Printing and dyeing wastewater treatment device and control method thereof

A technology for printing and dyeing wastewater and treatment equipment, which is applied in the direction of separation methods, chemical instruments and methods, and the preparation of test samples. It can solve problems such as socket damage, poor performance, and cumbersome operations for operators, and achieve replacement or maintenance. Easy, increase the service life, the effect of high service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further expressed below in conjunction with drawings and embodiments.

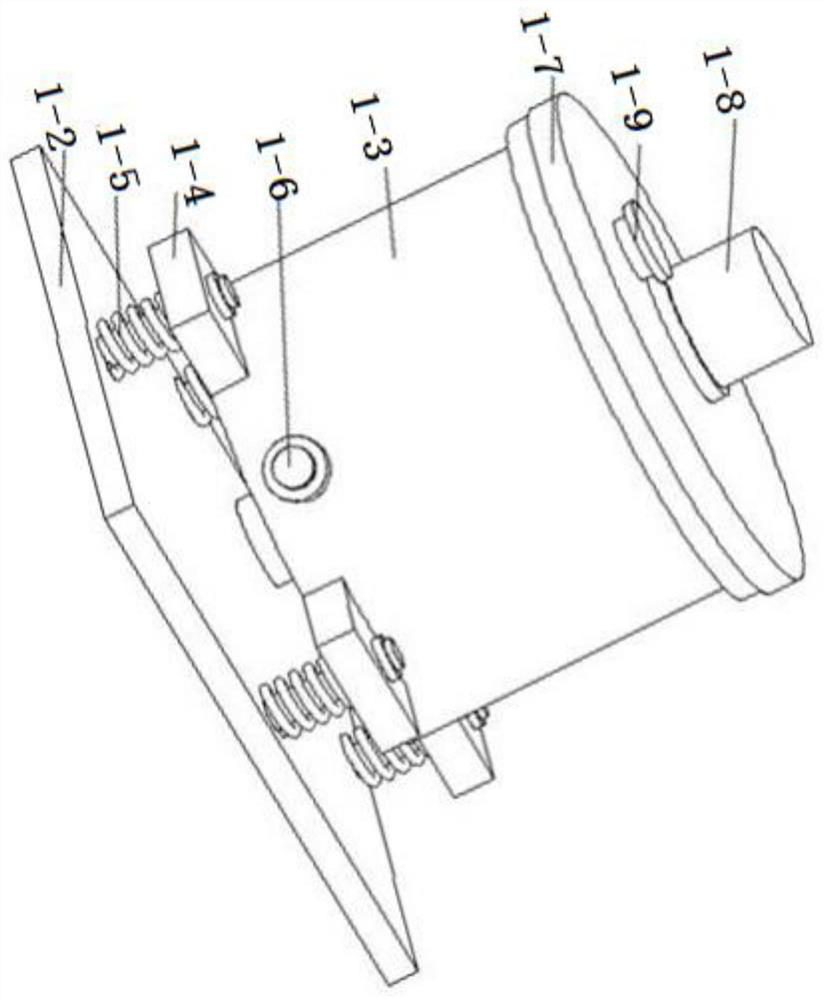

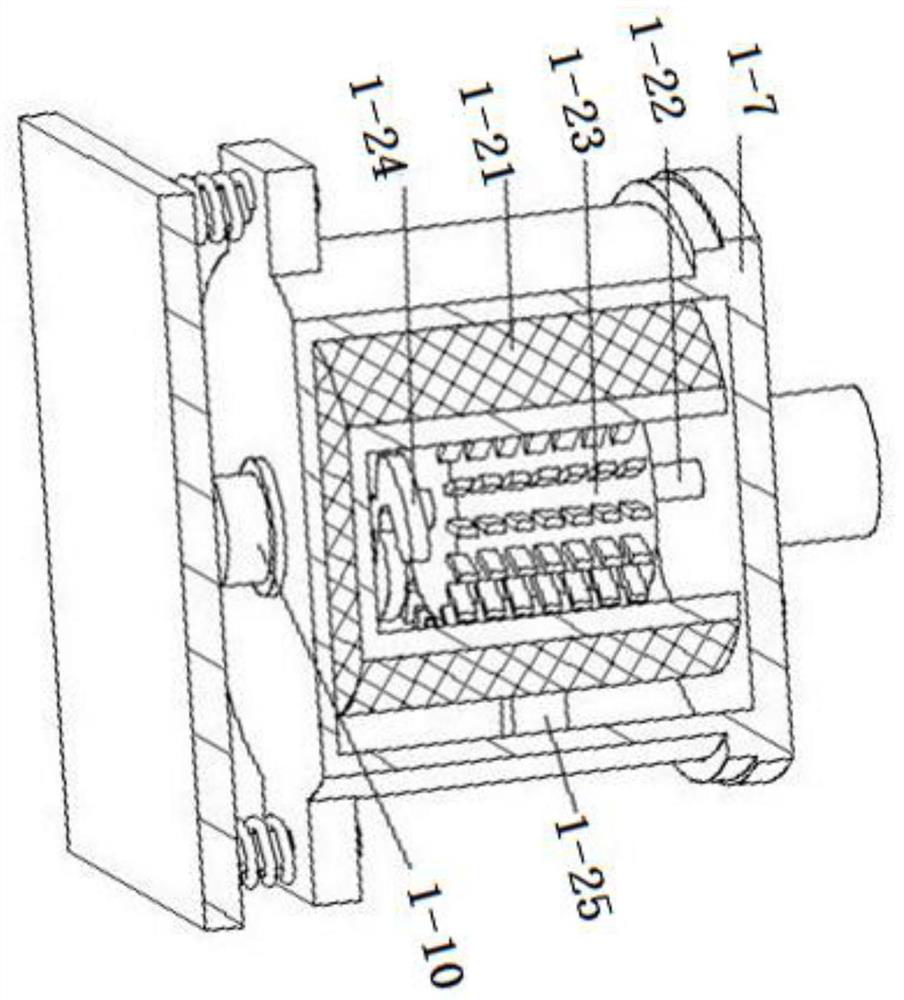

[0037] Such as Figure 1-Figure 5 As shown, the treatment devices for printing and dyeing wastewater include:

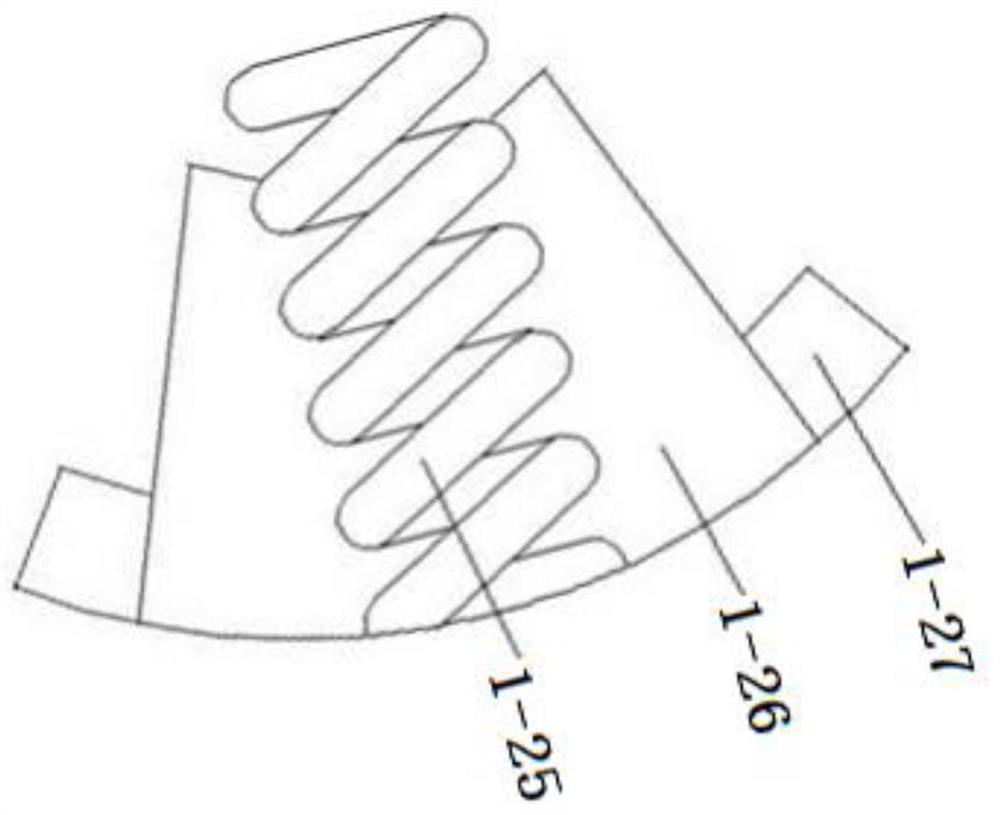

[0038] The sampling detection device used in the printing and dyeing wastewater treatment system, the sampling detection device used in the printing and dyeing wastewater treatment system includes a sampling inlet pipe for the sampling detection device in the printing and dyeing wastewater treatment system, used to remove impurities in the printing and dyeing wastewater buffer filter and a detection box for detecting the transmittance of printing and dyeing wastewater; the output end of the sampling water inlet pipe is connected to the detection box, and the buffer filter is arranged on the sampling water inlet pipe on the front side of the detection box; The detection box for the light transmittance of the printing and dyeing wastewater includes a box body, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com