Stone crushing device for hydraulic engineering

A technology of crushing device and water conservancy engineering, applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of reduced crushing efficiency, entry of gravel, low crushing efficiency, etc., and achieve the effect of improving crushing efficiency and avoiding clogging of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

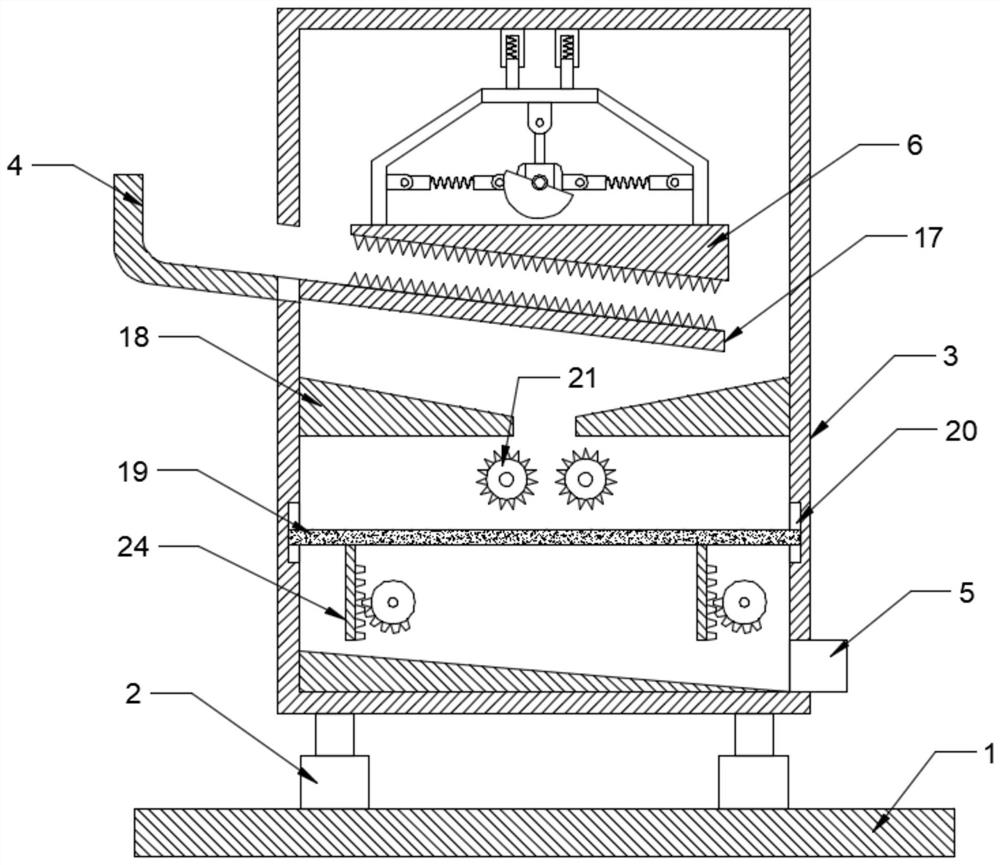

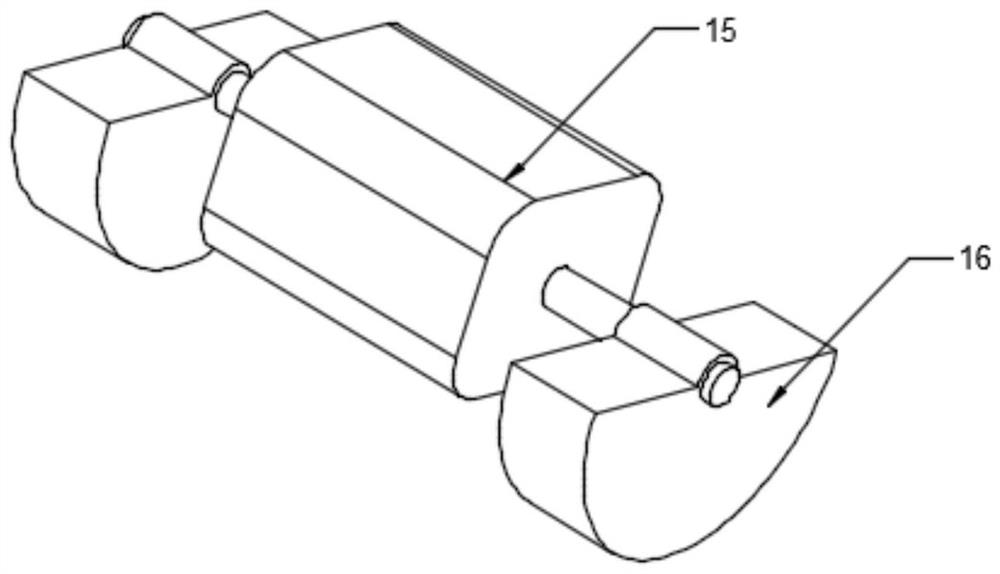

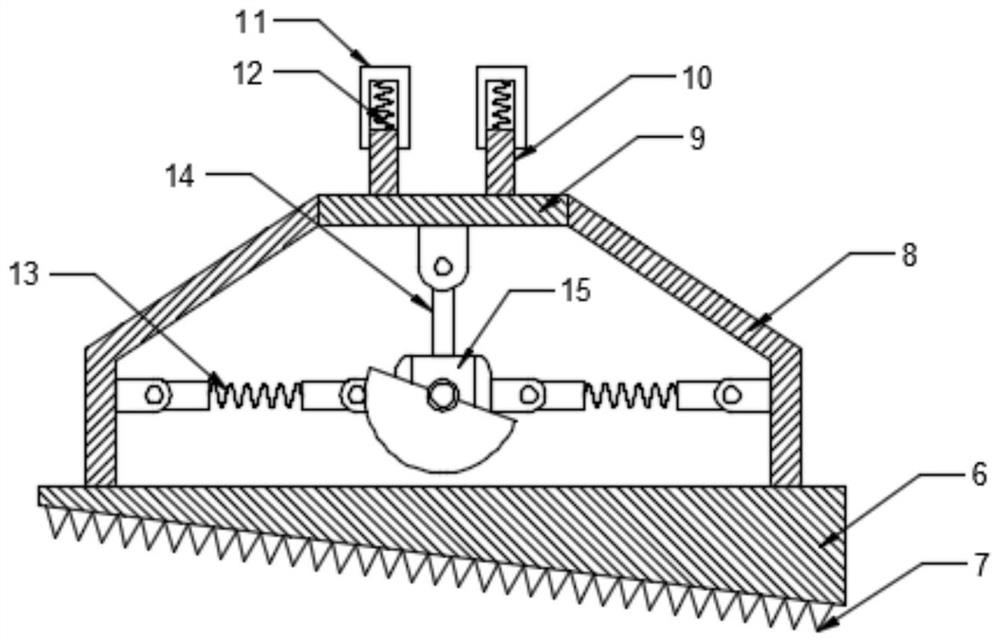

[0024] see Figure 1-4 , a stone crushing device for water conservancy projects, comprising a bottom plate 1 and a crushing box 3, a feed hopper 4 is connected to one side of the crushing box 3, a stone crushing assembly is arranged in the crushing box 3, and the stone crushing assembly The specific type is not limited. In this embodiment, preferably, the stone crushing assembly includes a vibrating plate 6, crushing teeth 7, a fixed frame 8, a fixed plate 9, a sleeve rod 10, a sleeve 11, a first damping spring 12, Connecting rod 14, biaxial motor 15, swing block 16 and extrusion plate 17, both swing blocks 16 are fan-shaped blocks and are symmetrically installed on the two output ends of biaxial motor 15, and the top of biaxial motor 15 is hinged by connecting rod 14 On the fixed plate 9, one end of a plurality of sleeve rods 11 is fixedly installed above the fixed plate 9, and the other end is movably sleeved in the sleeve 11 and a first damping spring 12 is arranged between...

Embodiment 2

[0032] In order to improve the crushing quality, this embodiment is further improved on the basis of Embodiment 1. The improvement is that a screening assembly is arranged under the crushing roller 21, and the specific type of the screening assembly is not limited. In this embodiment, preferably Yes, the screening assembly includes a sieve plate 19, a lift trough 20, a rack guide post 24, a rotating shaft 25, a transmission belt 26 and an incomplete gear 28, the lift trough 20 is set on the side wall of the crushing box 3, and the two ends of the sieve plate 19 are movably installed on the In the lifting groove 20, the rack guide post 24 is fixedly installed under the sieve plate 19 and intermittently cooperates with the incomplete gear 28. The incomplete gear 28 is fixedly installed on the rotating shaft 25, and the rotating shaft 25 is installed in the crushing box 3 in rotation. And one end extends to the outside of the crushing box 3 and is driven and connected with one of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap