Multi-station full-automatic ultrasonic cleaning device

A cleaning device, ultrasonic technology, applied in the direction of dry gas arrangement, cleaning method and utensils, cleaning method using liquid, etc., can solve the problems of inconvenient product handling, poor cleaning effect, difficult one-time cleaning products, etc., to prevent Impact and scratch each other, improve efficiency, and have good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

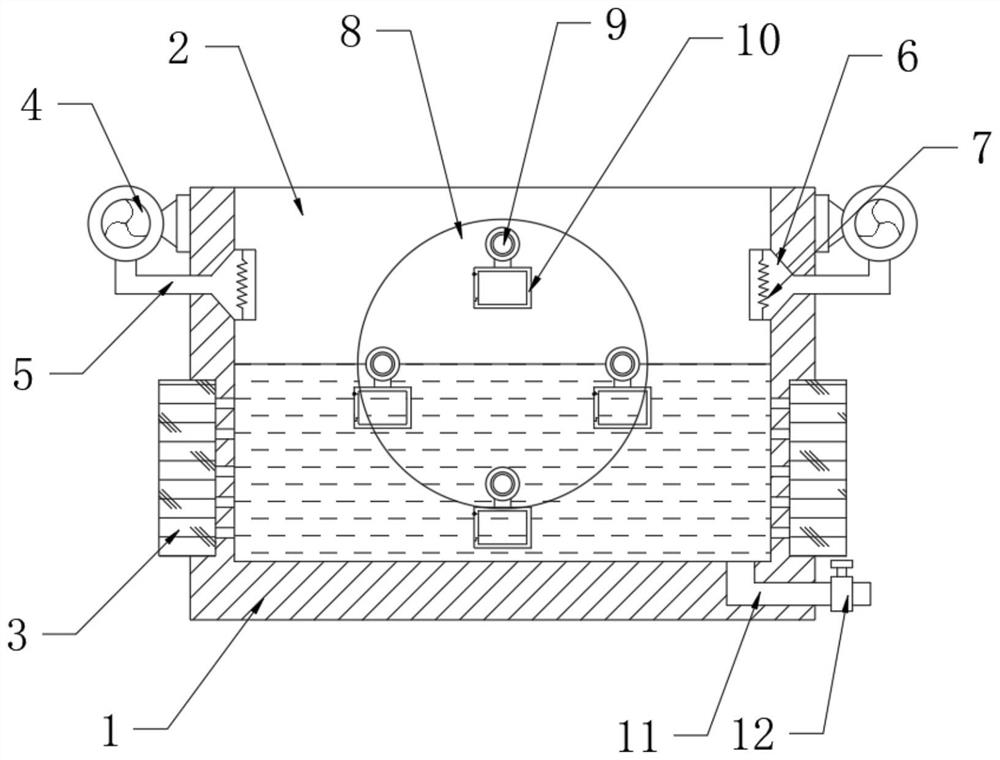

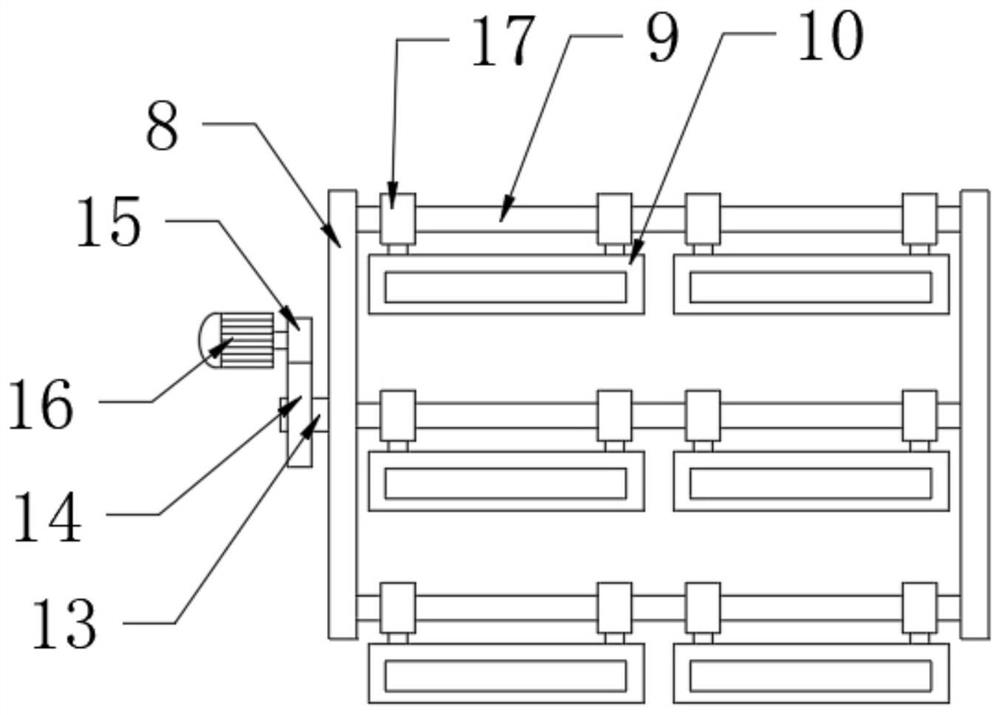

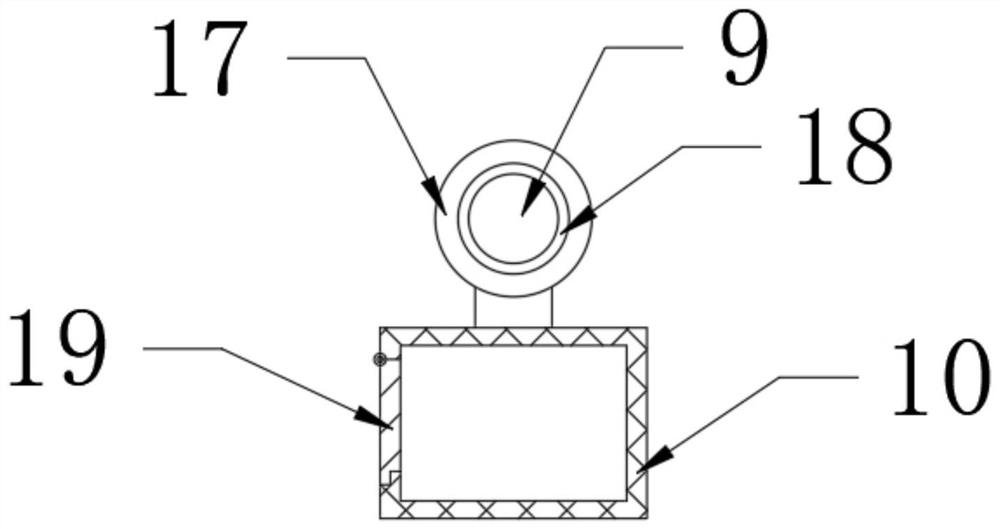

[0024] see figure 1 , figure 2 , image 3 , in an embodiment of the present invention, a multi-station automatic ultrasonic cleaning device includes a cleaning tank 1, a cleaning liquid is arranged inside the cleaning tank 1, a turntable 8 is installed in the middle of the cleaning tank 1 through a rotating shaft 13, and between the turntables 8 A support rod 9 is installed, and a storage grid 10 is installed on the support rod 9 through a connecting sleeve 17. There are multiple groups of the storage grid 10 and the support rod 9, which can store more products, and are convenient for washing and cleaning a large amount of products at one time. A cover door 19 is installed on one side of the rack 10, and a motor 16 is connected to one end of the rotating shaft 13. The motor 16 drives the turntable 8 and the rack 10 to rotate, so that the angle of cleaning can be adjusted, and it is convenient to remove the cleaned product from the washing machine. Taking and discharging fro...

Embodiment 2

[0031] see Figure 4 , figure 2 , image 3 , in an embodiment of the present invention, a multi-station automatic ultrasonic cleaning device includes a cleaning tank 1, a cleaning liquid is arranged inside the cleaning tank 1, a turntable 8 is installed in the middle of the cleaning tank 1 through a rotating shaft 13, and between the turntables 8 A support rod 9 is installed, and a storage grid 10 is installed on the support rod 9 through a connecting sleeve 17. There are multiple groups of the storage grid 10 and the support rod 9, which can store more products, and are convenient for washing and cleaning a large amount of products at one time. A cover door 19 is installed on one side of the rack 10, and a motor 16 is connected to one end of the rotating shaft 13. The motor 16 drives the turntable 8 and the rack 10 to rotate, so that the angle of cleaning can be adjusted, and it is convenient to remove the cleaned product from the washing machine. Taking and discharging fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com