Energy-saving cable material curing device

A curing and cable technology, which is applied in the field of curing devices, can solve the problems of difficult uniform and effective curing and low efficiency of cable materials, and achieve the effects of saving electric energy, improving the curing effect, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

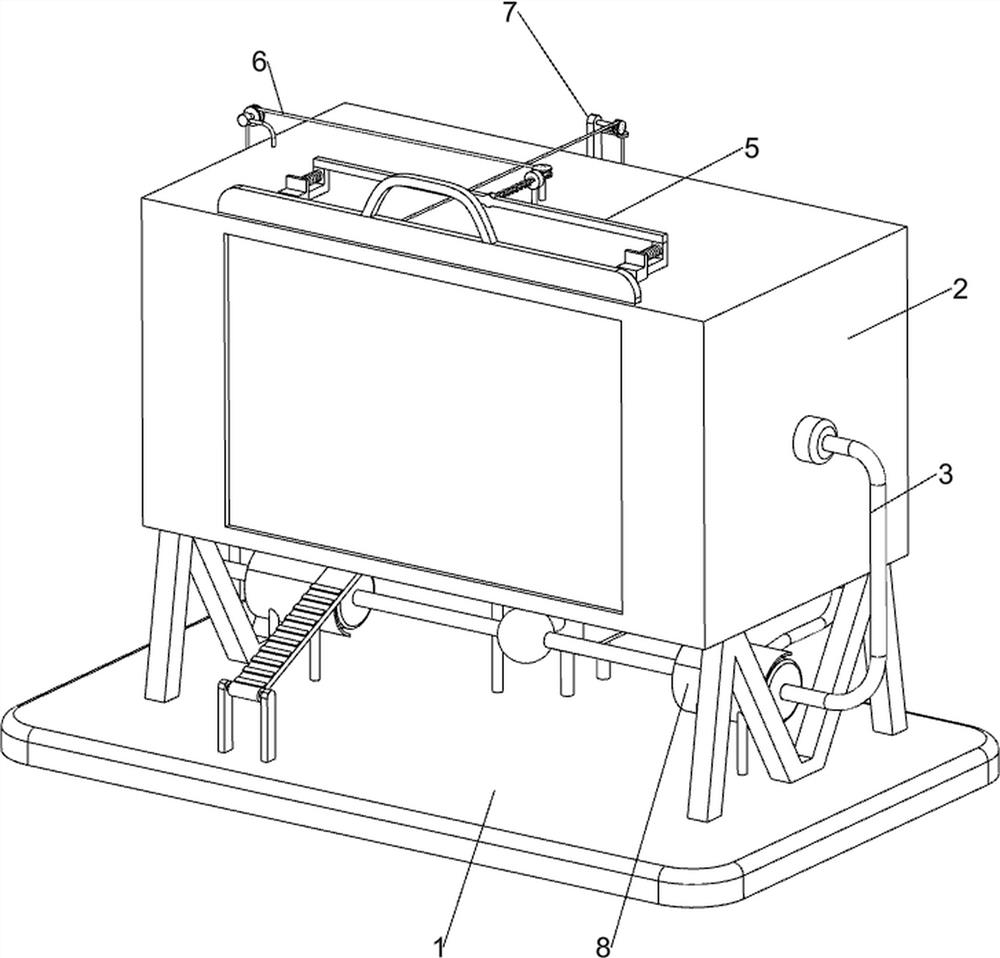

[0088] An energy-saving cable material aging device, such as figure 1 As shown, it includes a base 1 , a curing mechanism 2 and a heating mechanism 3 , the curing mechanism 2 is arranged on the top of the base 1 , and the heating mechanism 3 is arranged between the top of the base 1 and the curing mechanism 2 .

[0089] When people need to mature and heat the cable material, first put all the cable material into a certain part of the curing mechanism 2, and then start a certain part of the heating mechanism 3, and the heating mechanism 3 matures and heats the cable material. , turn off a certain part of the heating mechanism 3, and then take out the cable material after aging and heating.

Embodiment 2

[0091] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the curing mechanism 2 includes a bracket 20, a curing box 21, a cover plate 22 and a handle 23. The left and right sides of the top of the base 1 are symmetrically provided with brackets 20, and a curing box 21 is arranged between the tops of the brackets 20. The front part of the curing box 21 The sliding type is provided with a cover plate 22, and the corners of the rear side of the cover plate 22 are all provided with square holes, and a handle 23 is provided in the middle of the top of the cover plate 22.

[0092] When people need to ripen and heat the cable material, pull the handle 23 upwards, and the handle 23 drives the cover plate 22 to move upwards, then all the cable materials are put into the curing box 21, then push the handle 23 downwards to reset, and the handle 23 Drive the cover plate 22 to move down and reset, and then start a certain part of th...

Embodiment 3

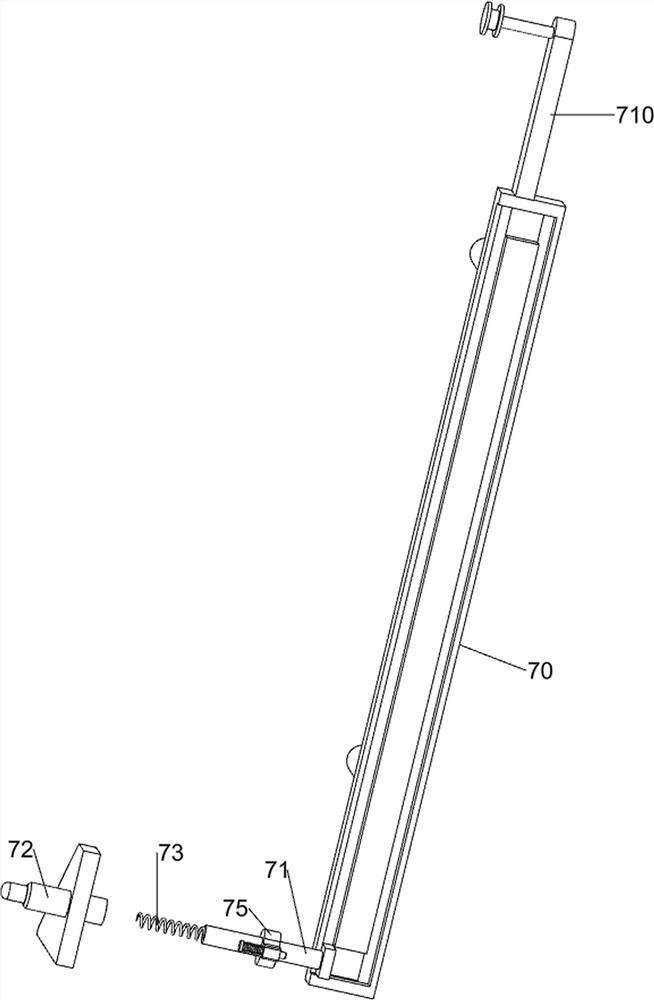

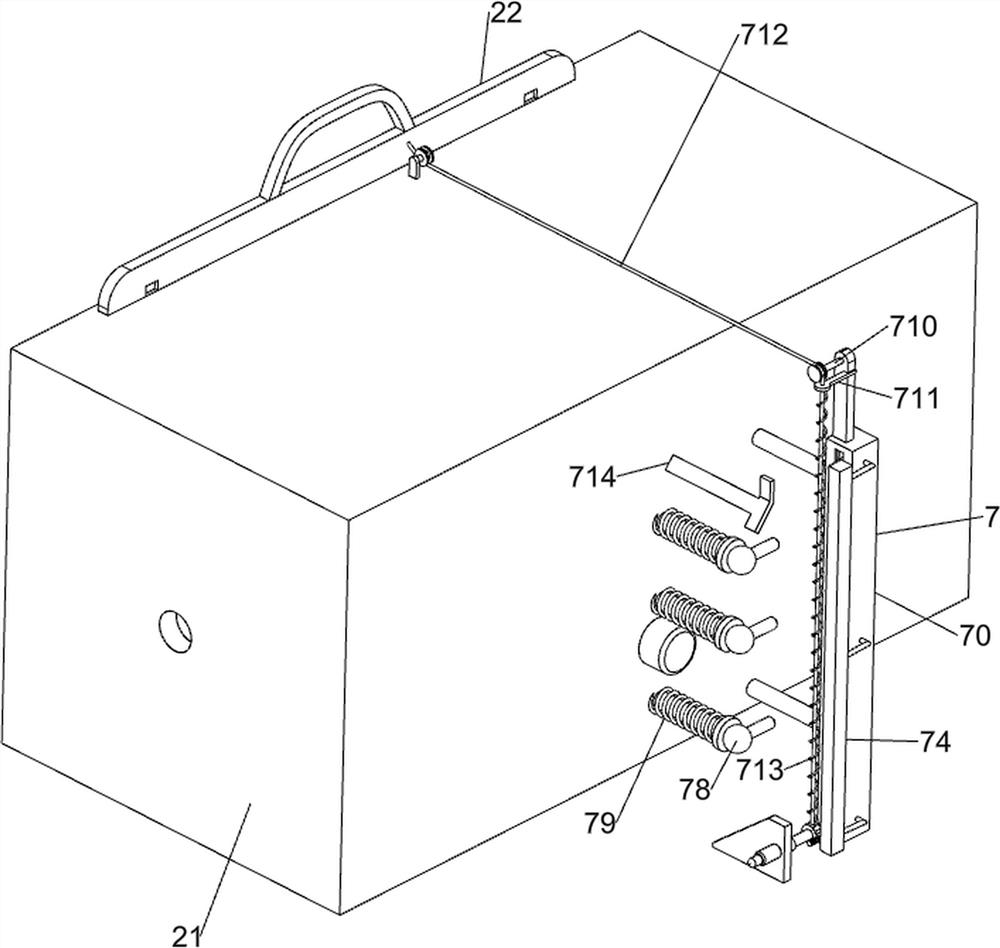

[0100] On the basis of Example 2, such as Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, it also includes a stepping assembly 6, and the stepping assembly 6 includes a sliding sleeve 60, a first winding wheel 61, a sliding shaft 62, a slide plate 63, a top plate 64, a pedal 65, a pull cord 66 and a compression spring 67, and the curing box 21 A sliding sleeve 60 is arranged in the middle of the rear side of the top, and a first winding wheel 61 is arranged on the left and right sides of the left part of the top rear side of the curing box 21. The rear portion of the rear portion is symmetrically provided with a slide shaft 62, a slide plate 63 is provided slidingly between the top of the slide shaft 62, a top plate 64 is provided on the right side of the bottom of the slide plate 63, and a pedal 65 is provided on the left side of the top front side of the base 1. The rotary type is provided with a pedal 65. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com