Internal heating type coking furnace for briquette coal cracking

An internal heating type, coking furnace technology, applied in coking ovens, special forms of dry distillation, petroleum industry, etc., can solve problems such as waste of resources, affecting product quality, affecting heat transfer efficiency, etc., to reduce waste of resources, improve product quality, contact The effect of smaller area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

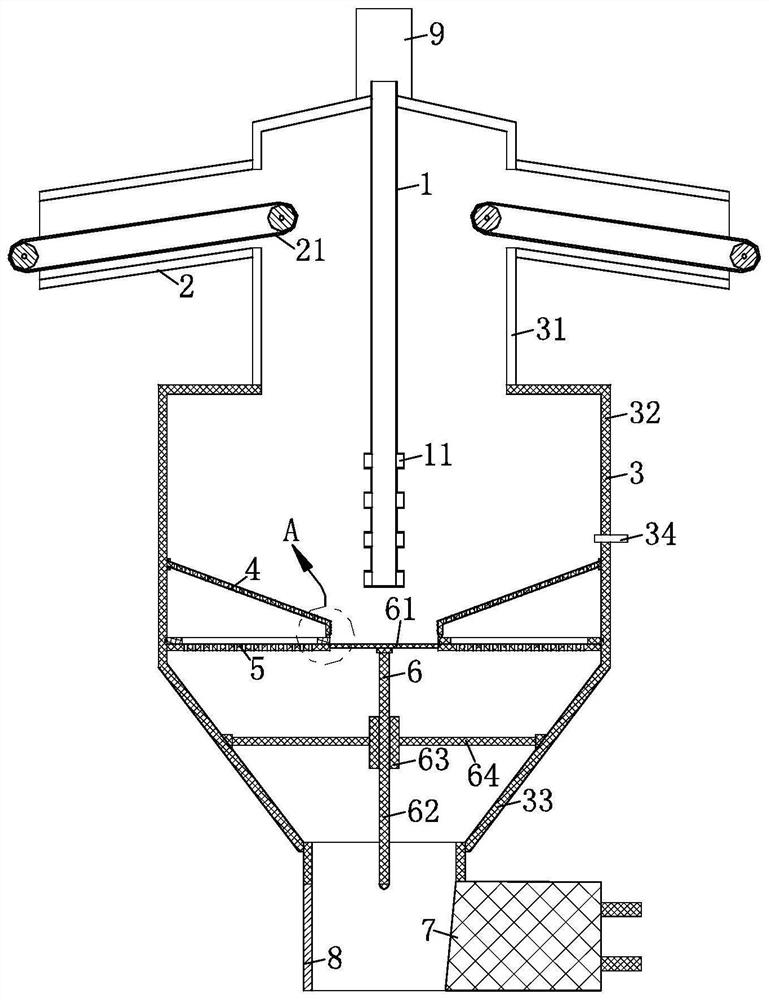

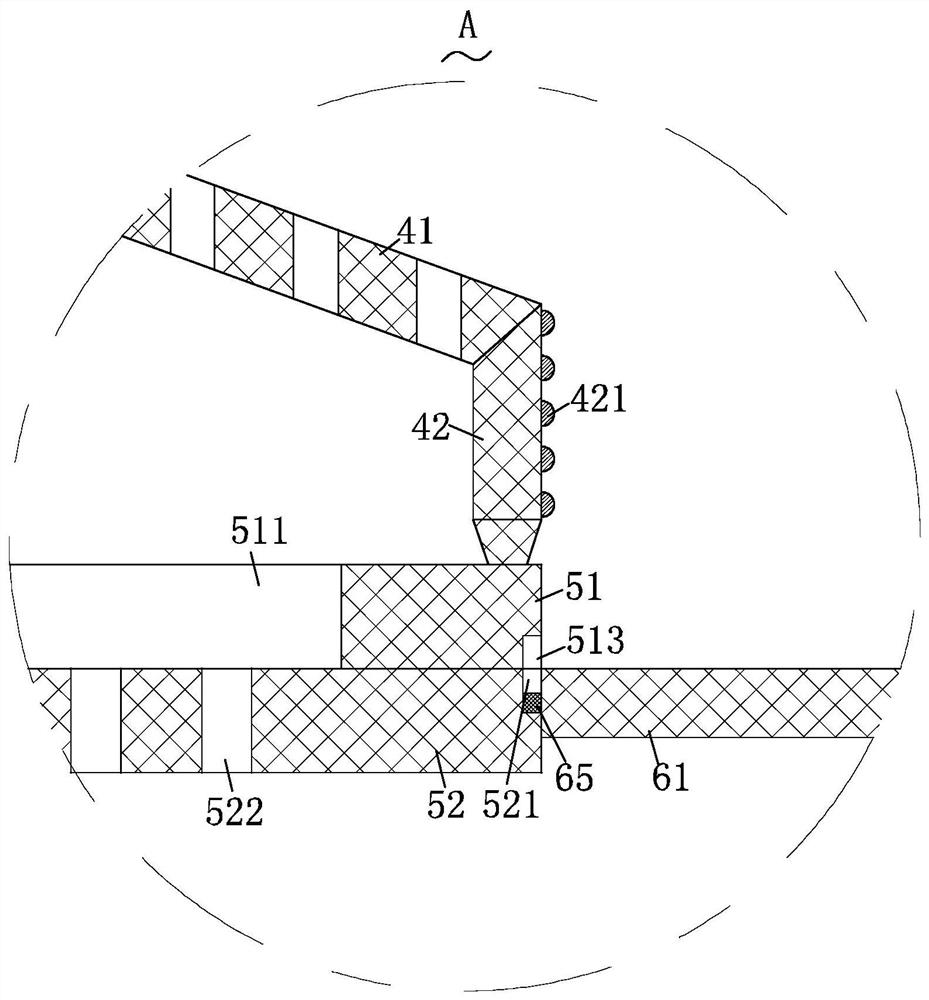

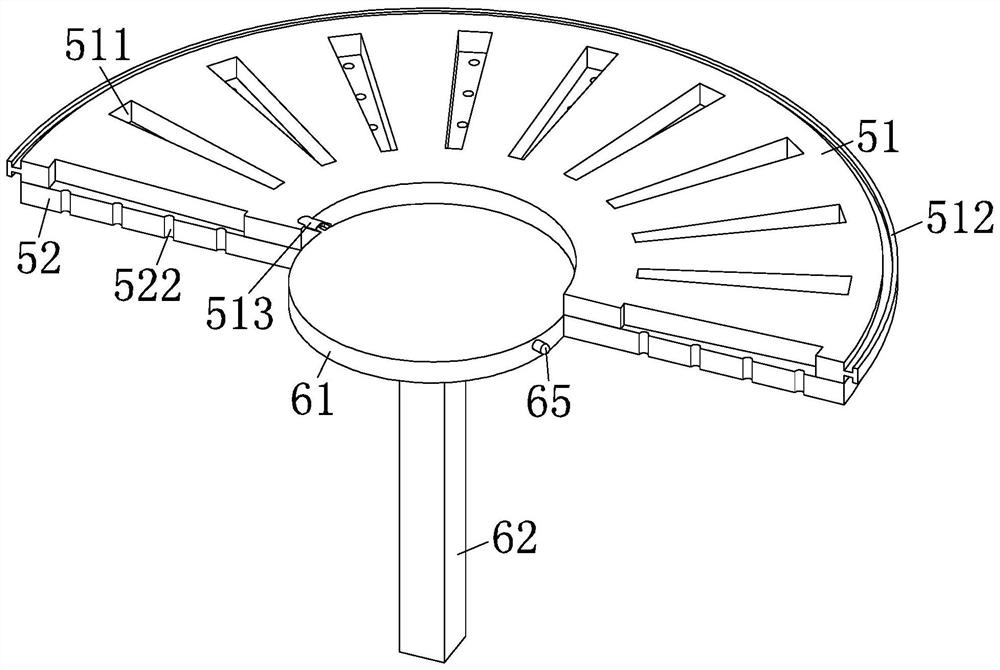

[0019] Such as Figure 1-Figure 4 As shown, a kind of internal heat type coking furnace for briquette cracking according to the present invention includes a furnace 3, and the furnace 3 includes a preheating zone 31, a combustion zone 32 and a maturing zone 33 arranged sequentially from top to bottom. The top of the preheating zone 31 is in the shape of an inverted funnel, and the top of the preheating zone 31 is provided with a smoke exhaust pipe 9 for exhausting flue gas, and the side of the preheating zone 31 is provided with a feed pipe 2. The feed pipe 2 is provided with a conveyor belt 21 for transporting briquettes, and the top of the preheating zone 31 is also provided with an air inlet pipe 1 for ventilation, and one end of the air inlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com