Material distributing valve externally provided with sealing pieces and replacing method of sealing pieces of material distributing valve

A technology of seals and distributing valves, which is applied in the direction of engine sealing, valve details, multi-way valves, etc., can solve the problems that affect the normal production work, the difficulty of replacing sealing strips, and the dead space of distributing valves, etc., to achieve replacement The effect of fast speed, long service life and avoiding the problem of material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through specific embodiments.

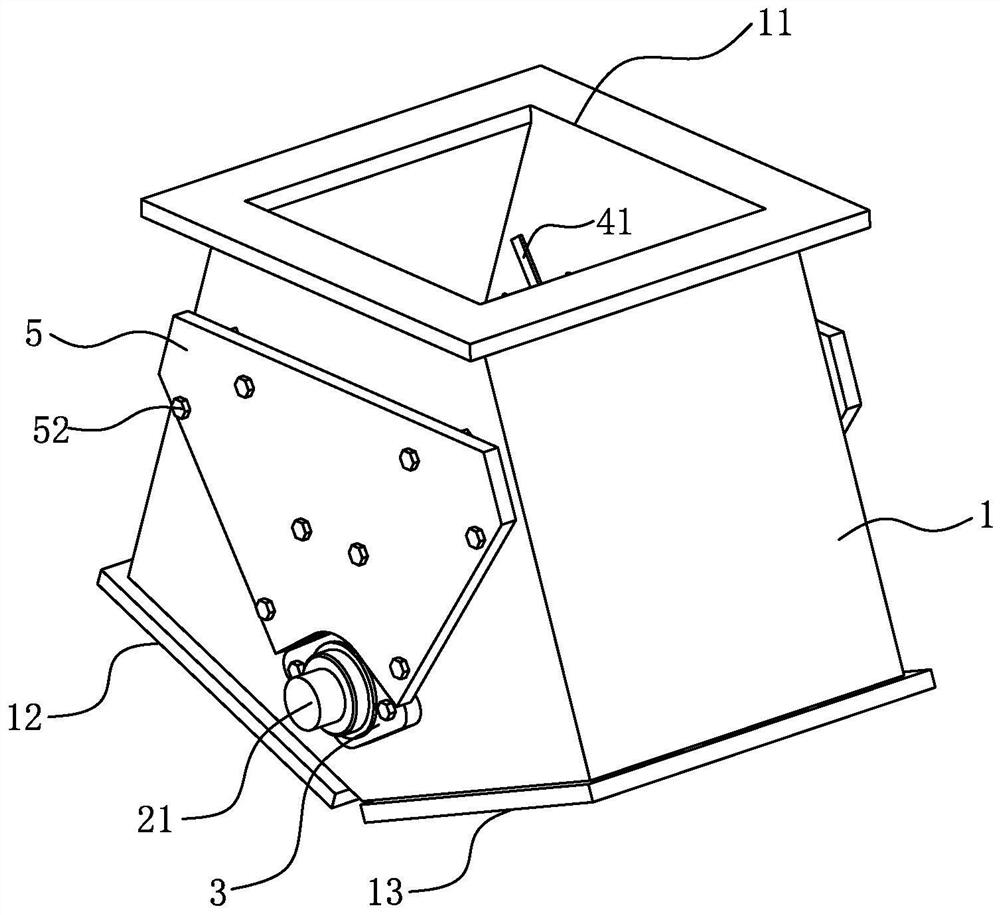

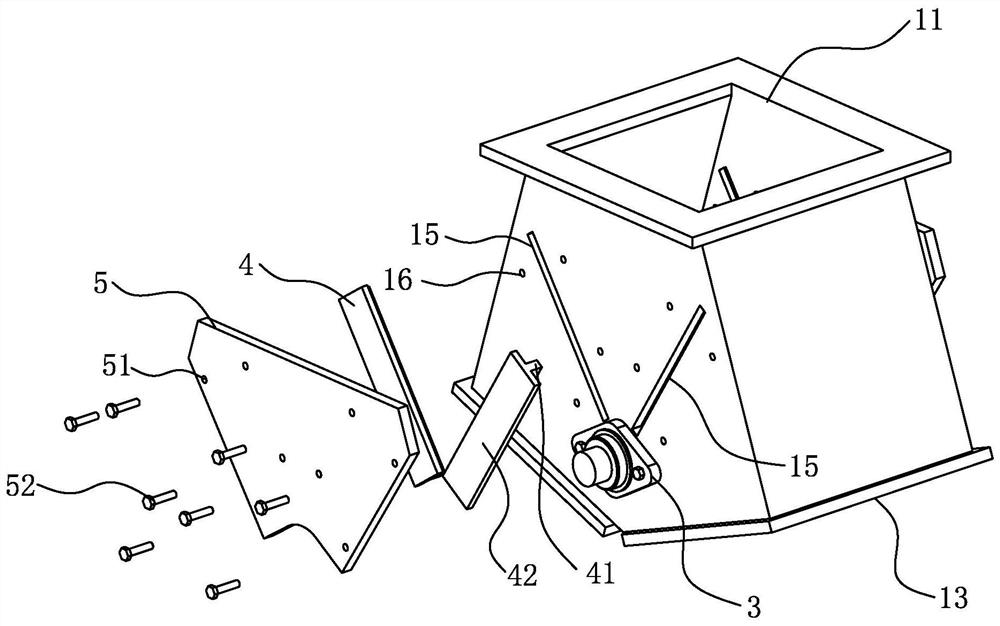

[0025] Take the three-way distribution valve as an example, refer to Figure 1 to Figure 6 As shown, a distributing valve with an external seal includes a valve body 1 , a valve plate 2 , a bearing seat 3 , a seal 4 , and a pressure plate 5 .

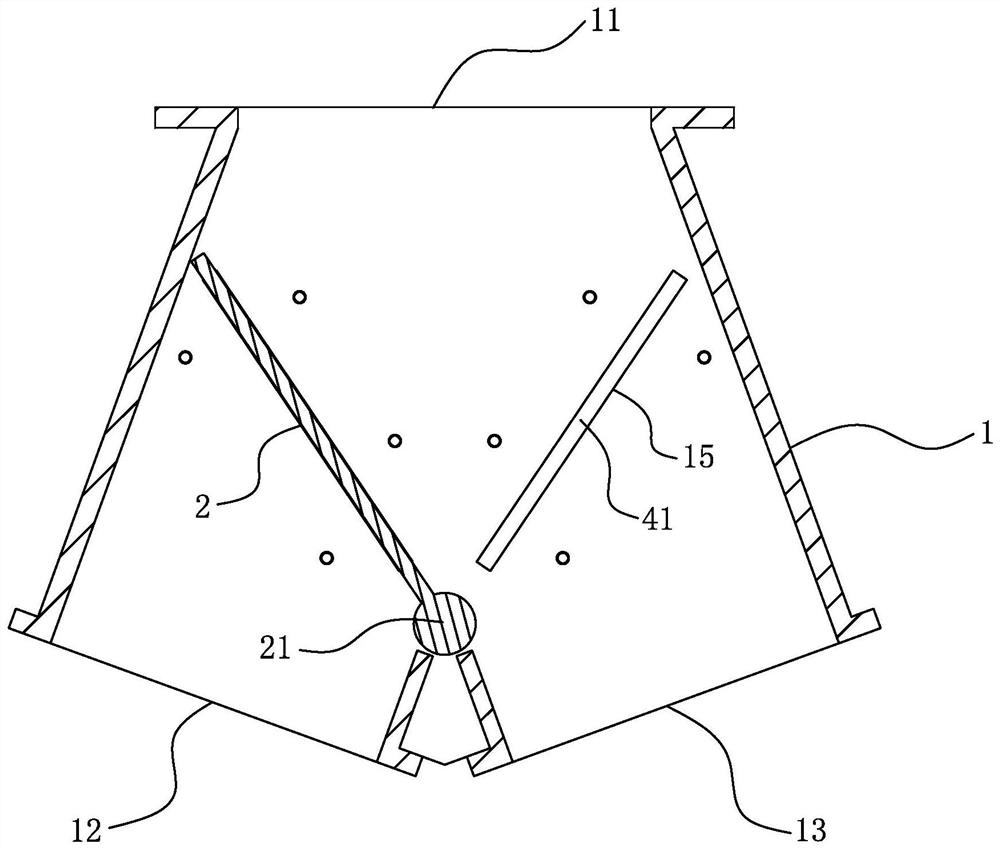

[0026] The valve body 1 includes an upper feed port 11, a lower first discharge port 12 and a second discharge port 13, the two side walls of the valve body 1 are provided with corresponding axial holes 14, and the bearing seat 3 Two bearing seats 3 are installed on the outer wall of the valve body 1 corresponding to the positions of the two shaft holes 14. The valve plate 2 includes a rotating shaft 21. 3 connection, so that the valve plate 2 is rotatably arranged in the valve body 1, and the valve plate 2 selectively closes the first discharge port 12 or the second discharge port 13 through rotation.

[0027] The valve body 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com