Method for repairing trenchless coating lining of large-diameter drainage pipeline

A technology for drainage pipes and repair methods, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve problems such as prominent safety risks, large environmental pollution, and pipe leakage, and achieve small safety risks and resource investment Less, the effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0036] In conjunction with the accompanying drawings.

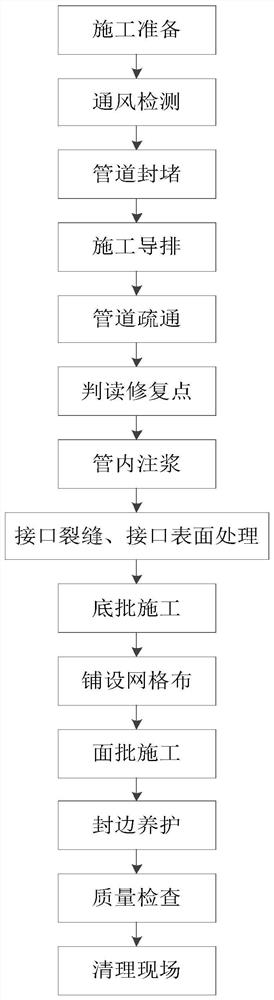

[0037] The non-excavation coating lining repair method for large-diameter drainage pipelines includes the following steps:

[0038] (1) Construction preparation: Before the official construction, it is necessary to go through the administrative approval procedures for road-occupying construction, and carry out traffic evacuation and construction site layout according to the approval situation.

[0039] (2) Ventilation detection: Set up a blower fan and an exhaust fan at the two wellheads of the construction section to continuously supply air and ventil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com