Light beam pointing control system based on conical mirror and deviation correction method thereof

A beam pointing and control system technology, applied in optics, optical components, instruments, etc., can solve problems such as the influence of detection accuracy, deviation of detector installation position, complex structure of beam pointing control system, etc., to achieve stable detection results and lower accuracy requirements , the effect of reducing the resolution requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

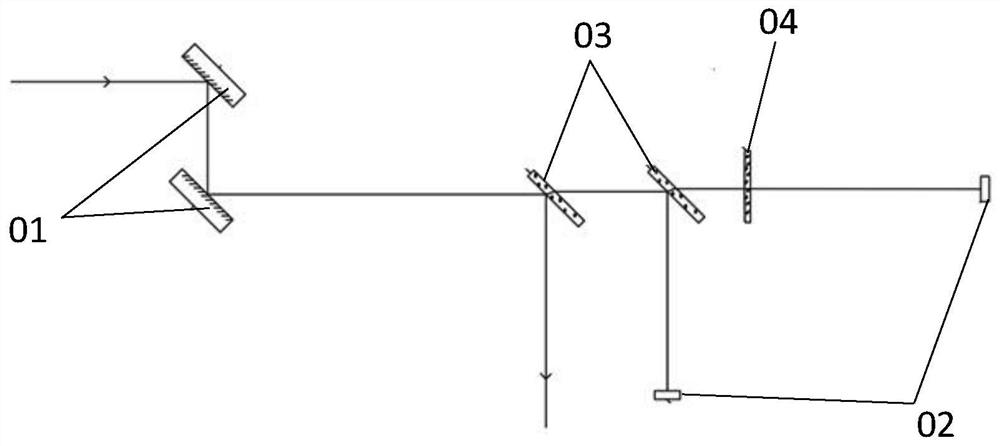

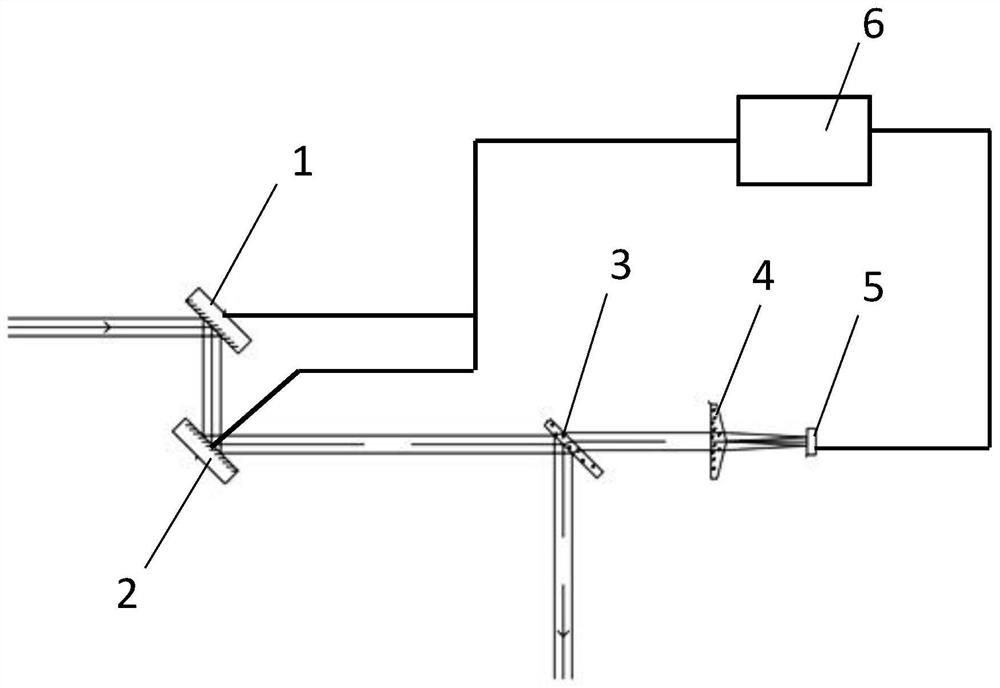

[0037] A beam pointing control system based on axicon mirrors. First, two fast deflecting mirrors are set in the laser light path to fine-tune the angle and position offset of the laser beam. After the fast deflecting mirrors, a beam splitter 3 is used to split a beam of light It is used as a sample laser beam to judge the offset of the laser beam. The sampled laser beam split by the beam splitter 3 is shaped into a Bessel beam after passing through the cone mirror 4, and a high-resolution detector 5 is set within the focal depth range of the Bessel beam to detect the position and position of the beam. energy distribution.

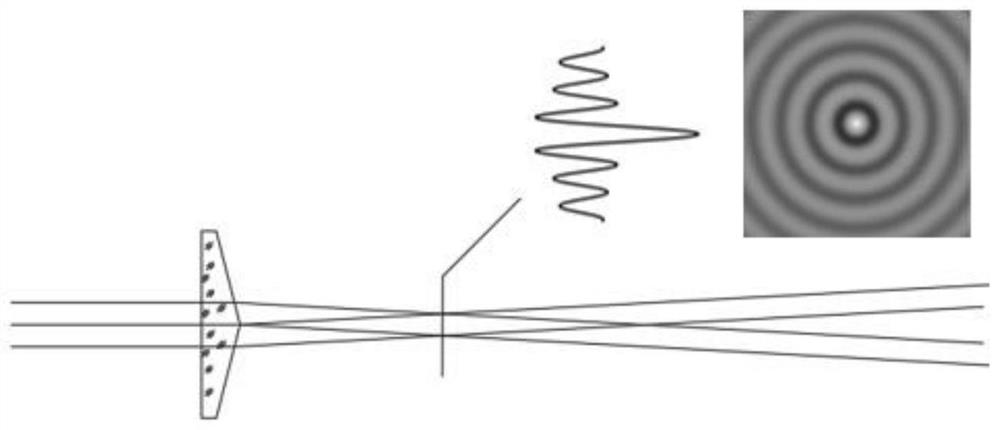

[0038] The principle of Bessel beam generation is as follows figure 2 As shown, the light beam passes through the axicon 4 and is divided into two beams of light. At the same time, the two beams of light have a certain angle and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com