A liquid crystal polymer substrate and its processing method

A technology of liquid crystal polymer and processing method, applied in the directions of instruments, nonlinear optics, optics, etc., can solve the problems of poor high-frequency characteristics of liquid crystal polymer film, low bonding strength, poor heat resistance of liquid crystal polymer film, etc. Excellent peel strength, high peel strength, effect of preventing interlayer separation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

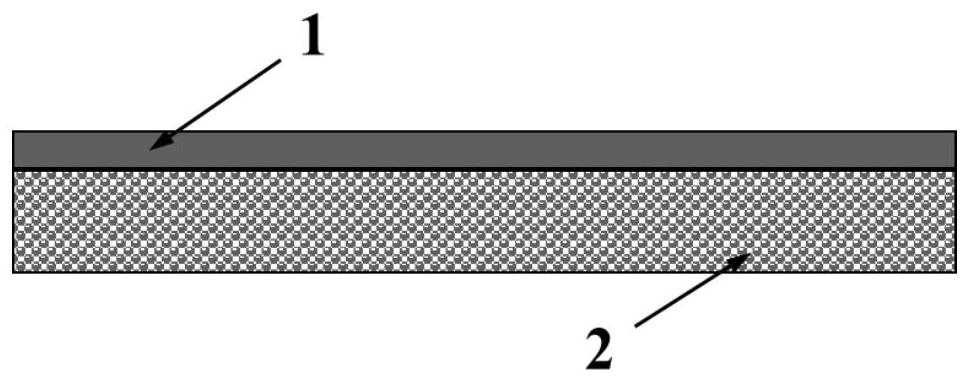

[0074] Melting point is T m1 The liquid crystal polymer is a liquid crystal copolyester of p-hydroxybenzoic acid, 4,4'-dihydroxybiphenyl and terephthalic acid with a melting point of 320 ° C, and a melting point of T m2 For the liquid crystal polymer, the liquid crystal copolyester of p-hydroxybenzoic acid and 6-hydroxy-2-naphthoic acid with a melting point of 280°C is selected, and the liquid crystal polymer material is dried and pretreated in a vacuum drying oven at a drying temperature of 150°C. The drying time is 5 hours, and the water content of the resin after drying is less than 300ppm. T according to melting point m2 The mass percentage of the liquid crystal polymer resin accounting for the total resin amount of the liquid crystal polymer film is 1.0%. The two liquid crystal polymers are evenly mixed, and then blended and granulated by a co-rotating twin-screw extruder, and blended to form The granulated liquid crystal polymer material is dried in a vacuum drying ove...

Embodiment 2

[0077] The difference from Example 1 is that the melting point is T m2 The liquid crystal polymer resin accounts for 5.0% by mass of the total resin amount of the liquid crystal polymer film.

Embodiment 3

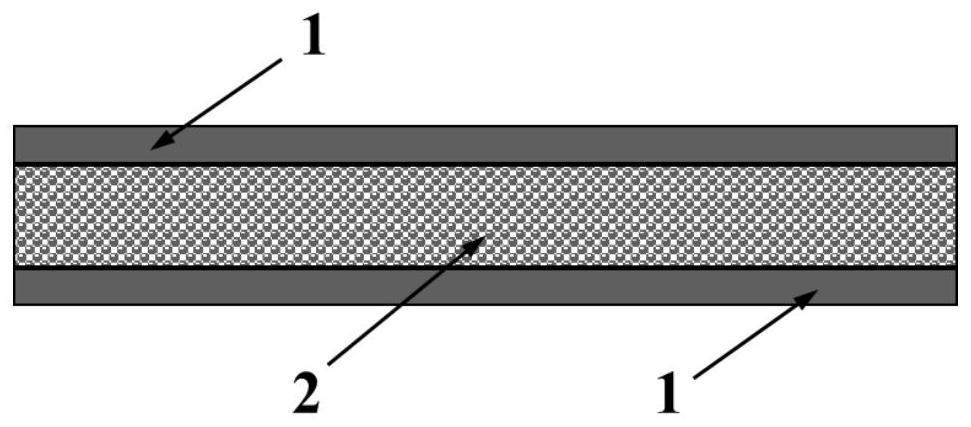

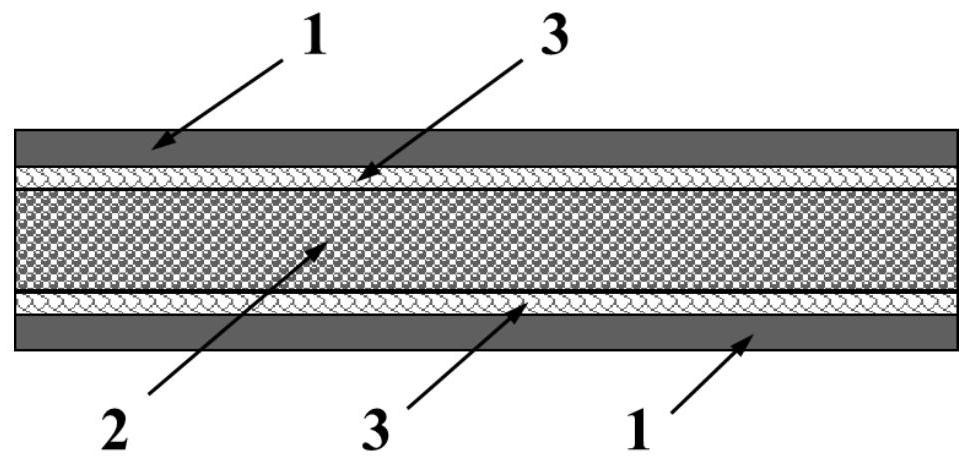

[0079] The difference from Example 2 is that both sides of the composite liquid crystal polymer film 2 are covered with copper foil, that is, they are stacked in the order of copper foil / composite liquid crystal polymer film 2 / copper foil, and then hot-pressed to obtain Liquid crystal polymer substrate (such as figure 2 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com