Transmission type electronic control terahertz antenna based on liquid crystal material

A liquid crystal material and terahertz technology, applied in antennas, antenna arrays, antenna grounding devices, etc., can solve the problems of limited beam scanning range and terahertz antenna feed source occlusion, etc., and achieve the effect of convenient processing and simple design scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

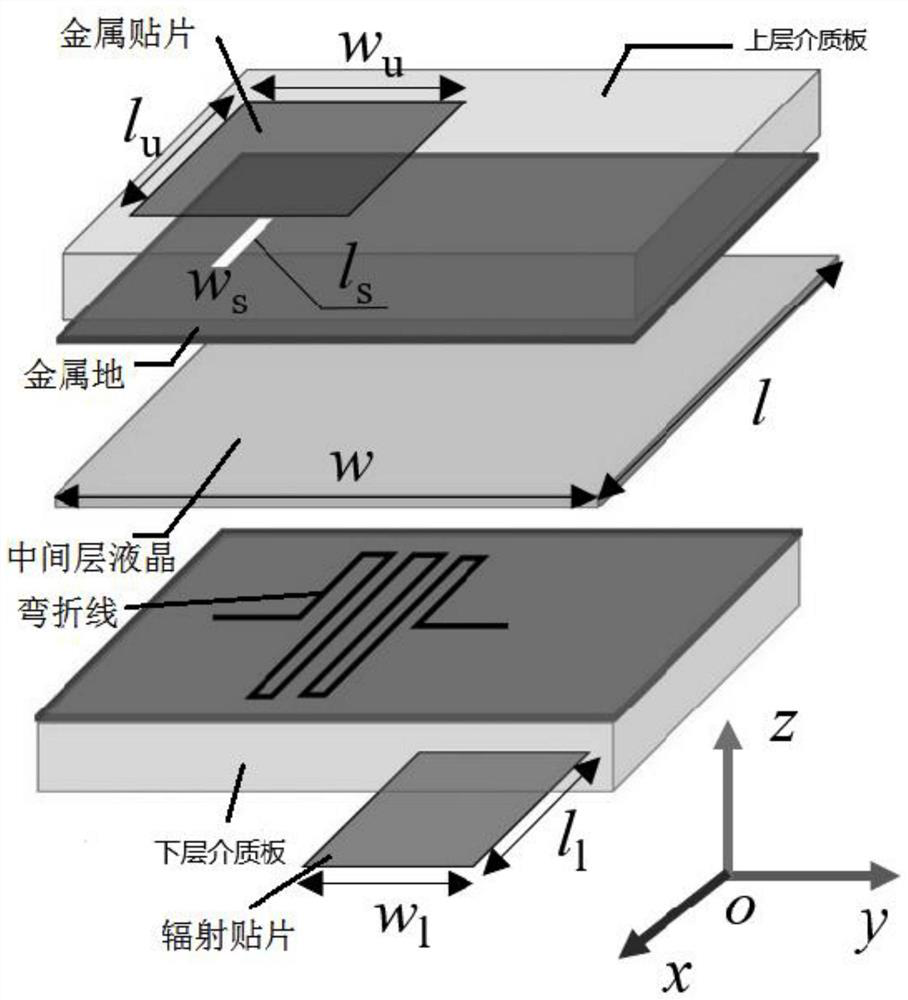

[0022] according to Figure 1 to Figure 5 As shown, the present invention provides a transmissive electronically controlled terahertz antenna based on liquid crystal materials, a transmissive electronically controlled terahertz antenna based on liquid crystal materials, and the terahertz antenna includes: an upper dielectric plate, a metal patch, a metal Ground, middle layer liquid crystal, bending line, radiation patch and lower dielectric board;

[0023] The metal patch and the metal ground are respectively etched on the upper surface and the lower surface of the upper dielectric board, the metal ground structure etches a slit structure, and the middle layer liquid crystal is encapsulated between the upper dielectric board and the lower dielectric board, and the curved The folding line is processed on the upper surface of the lower dielectric board, and the radiation patch is etched on the lower surface of the lower dielectric board.

[0024] The size of the gap structure i...

specific Embodiment 2

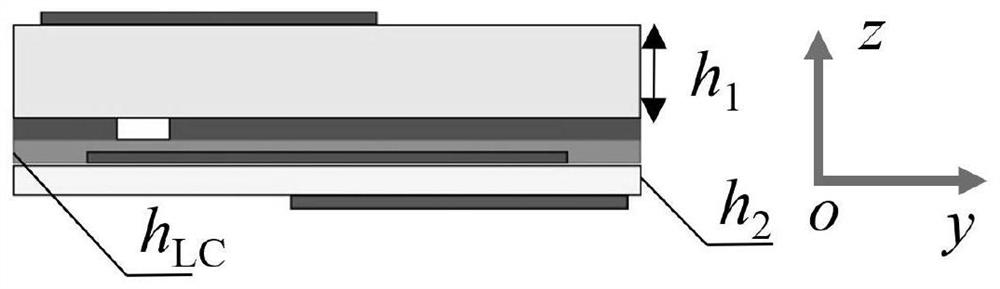

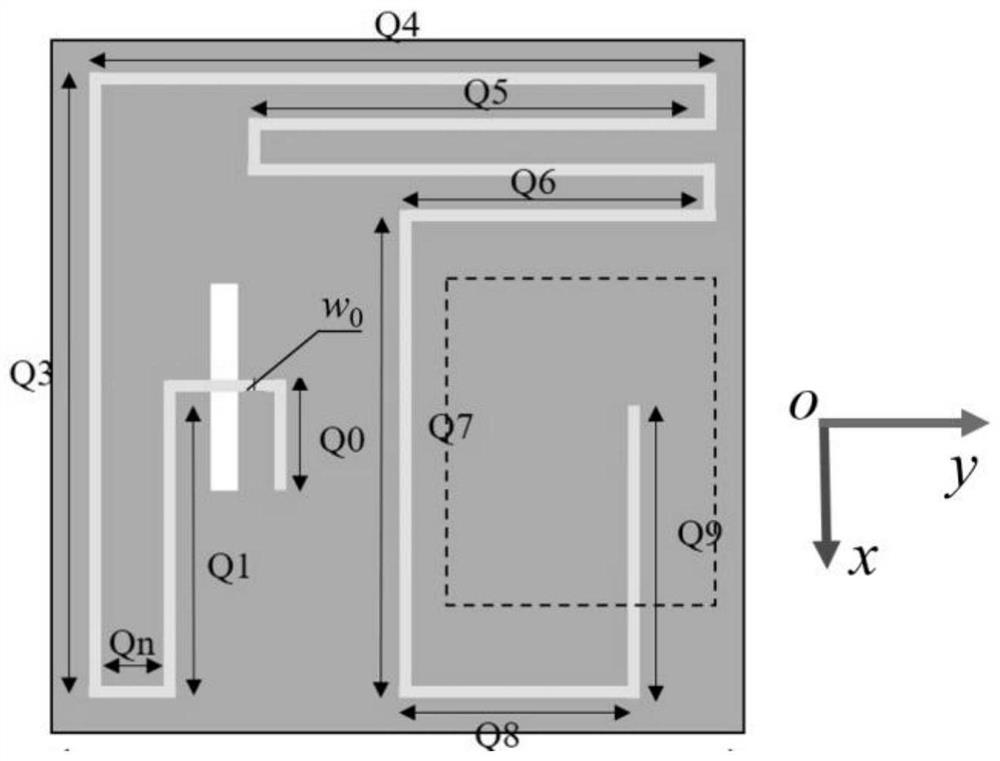

[0030] The structure of the transmissive liquid crystal electronically controlled terahertz antenna unit designed by the present invention is as follows: Figure 1-Figure 3 As shown, it can be seen that the unit structure is composed of an upper layer slot-coupled microstrip antenna, a middle layer liquid crystal, and a lower layer microstrip antenna. The upper slot-coupled microstrip antenna is composed of an upper dielectric plate, a metal patch, and a metal ground, and the lower layer microstrip antenna is composed of a lower dielectric plate, a bending line, and a radiation patch; among them, the metal patch and metal patch of the upper slot-coupled microstrip antenna The ground structures are respectively etched in the thickness h 1 The upper medium plate and the lower surface. By etching size w in the metal ground structure s × l s (value range: 0.01λ 0 ≤w s ≤0.02λ 0 and 0.25λ 0 ≤l s ≤0.35λ 0 ) gap structure to realize the coupling of the electromagnetic wave en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com