Permanent magnet motor and oil pumping device using the permanent magnet motor

A technology for permanent magnet motors and components, applied in electromechanical devices, synchronous motors with stationary armatures and rotating magnets, magnetic circuits, etc. structure and other issues, to achieve the effect of high reliability and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

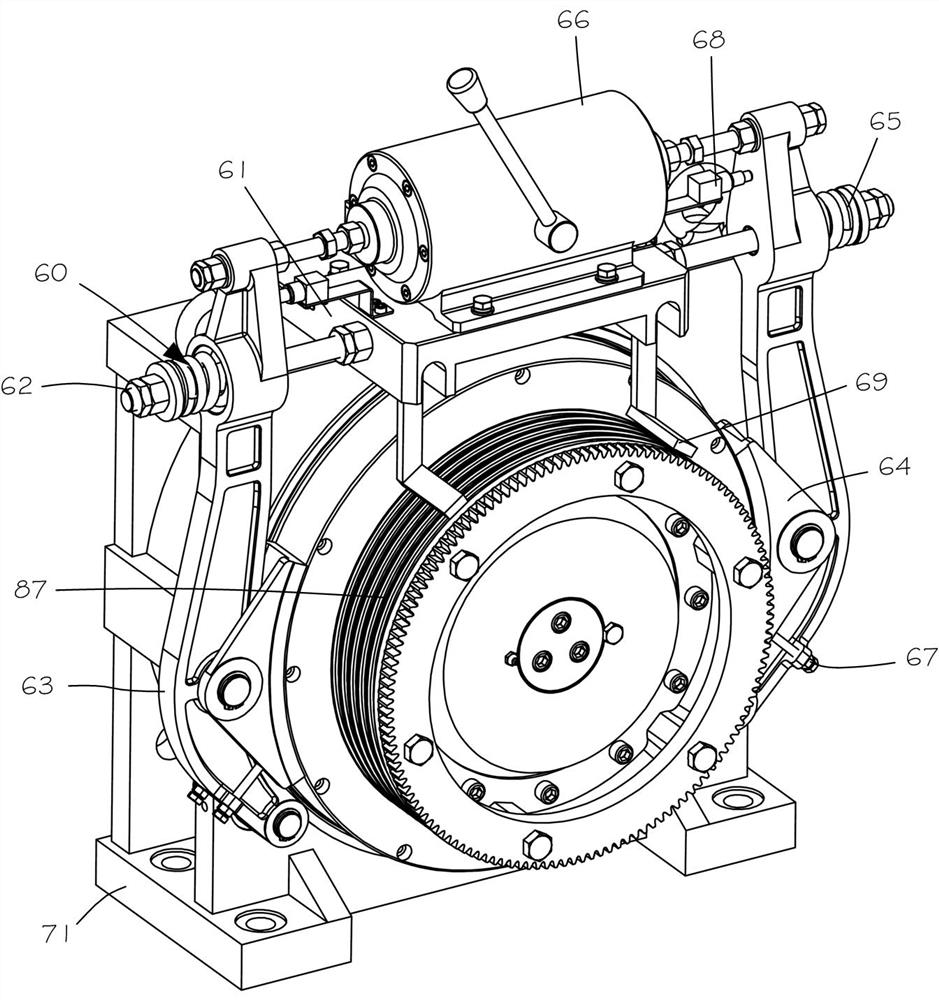

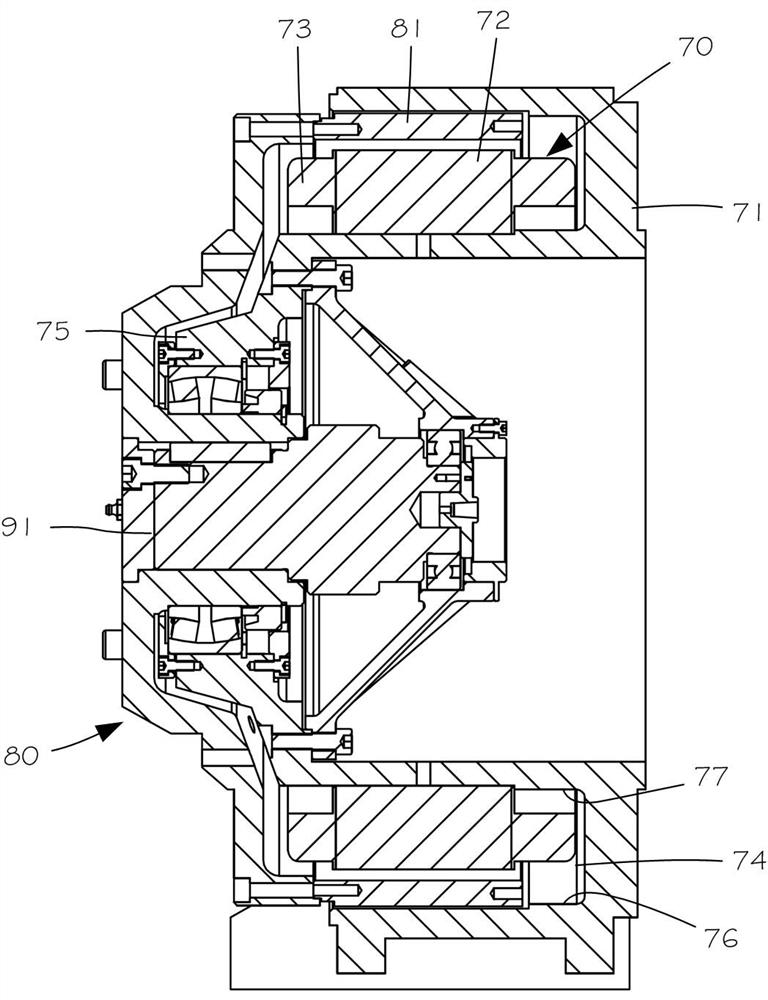

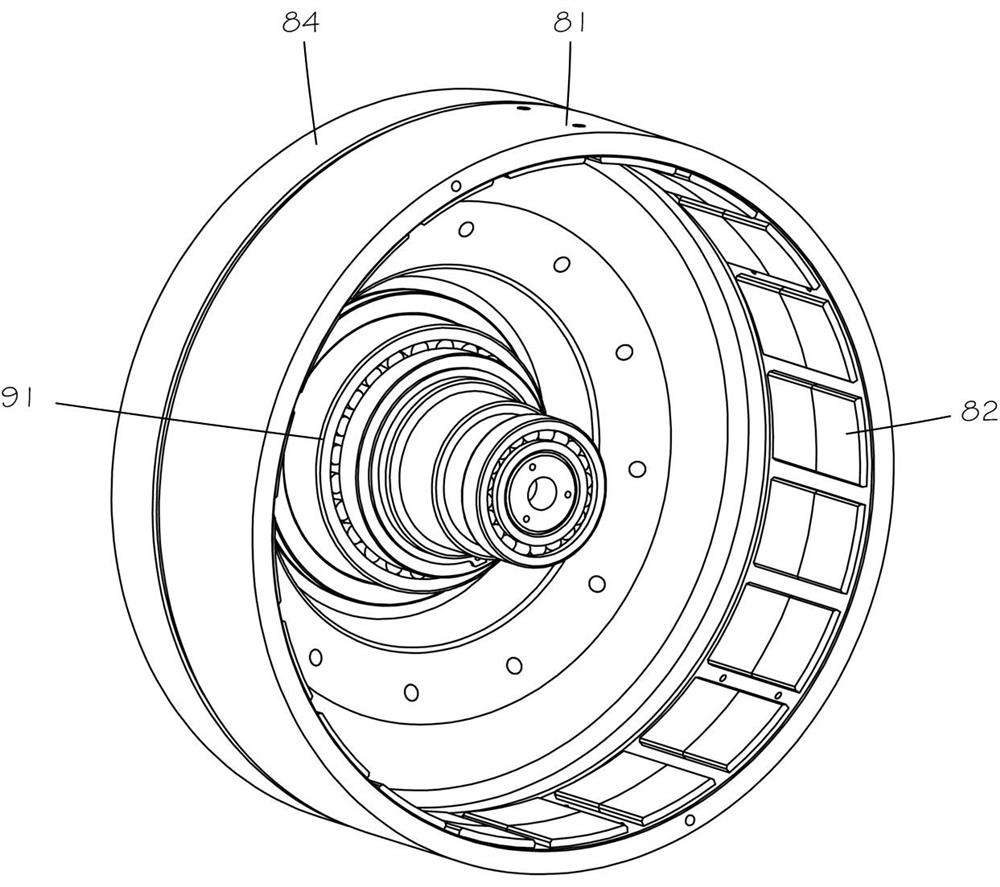

[0029] Such as Figures 1 to 6 The shown permanent magnet motor 11 of the present invention includes a stator assembly 70 , a rotor assembly 80 , and a braking assembly 60 . The stator assembly 70 includes a housing 71 , a stator core 72 , and a stator winding 73 . The housing 71 has a coaxial annular groove 74 and a support column 75 . The annular groove 74 has a large-diameter wall surface 76 and a small-diameter wall surface 77 , and the small-diameter wall surface 77 is the outer surface of the support column 75 . The stator core 72 is sleeved on the support column 75 , and the stator winding 73 is installed on the stator core 72 . An alternating magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com