Foaming filling reinforced sealing material for coal field fire extinguishing grouting and application thereof

A technology for grouting and coalfields, which is applied in fire prevention equipment, fire prevention, safety devices, etc., and can solve problems such as poor fluidity, high risk of recombustion, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

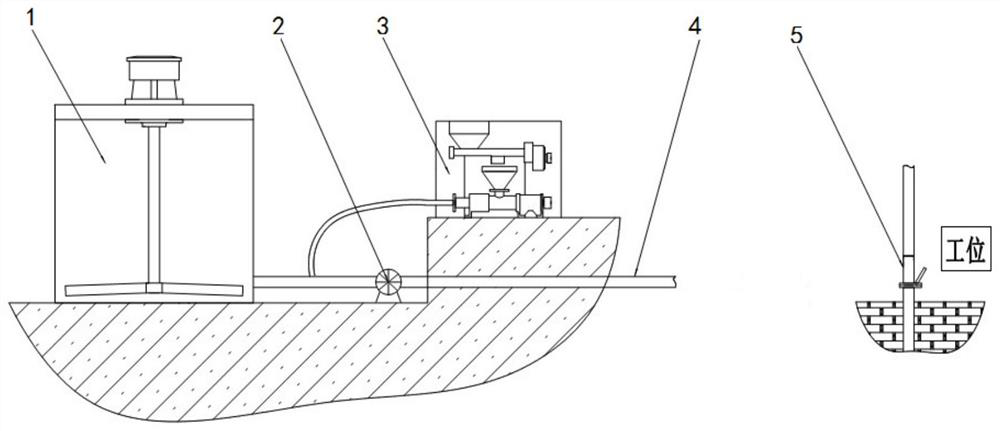

Image

Examples

preparation example Construction

[0022] In a preferred embodiment, it is prepared by the following method: the cement, gypsum, alumina, fly ash, quicklime, foaming agent, foam stabilizer, gelling agent, retarder, expansion Type flame retardant, antistatic agent, pulverized, mixed and stirred evenly to form a powdery solid, and the foaming filling reinforcement airtight material for coal field fire extinguishing grouting is obtained. The preparation method of the foaming filling and reinforcing sealing material for coal field fire extinguishing grouting is simple, and is beneficial to cost saving.

[0023] Another aspect of the present invention provides the application of the foam filling reinforcement sealing material for coal field fire extinguishing grouting described in any of the above embodiments in coal field fire extinguishing. The technical scheme of the present invention obtains the foaming filling reinforcement airtight material for grouting for coal field fire extinguishing by improving the compon...

Embodiment 1

[0029]Foaming filling reinforcement airtight material for coal field fire extinguishing grouting, including the following raw materials by weight: 30 parts of cement, 10 parts of gypsum, 15 parts of alumina, 15 parts of fly ash, 15 parts of quicklime powder, foaming agent α-ene Sodium sulfonate (AOS) 3 parts, foam stabilizer nitrilotriacetic acid (SH-193) 1 part, gelling agent 1 part, retarder lignosulfonate 2 parts, intumescent flame retardant (IFR) 1 part, 1 part of antistatic agent (ASA).

Embodiment 2

[0031] Foaming filling reinforcement airtight material for coalfield fire-fighting grouting, including the following raw materials by weight: 35 parts of cement, 15 parts of gypsum, 20 parts of alumina, 20 parts of fly ash, 20 parts of quicklime powder, foaming agent α-ene Sodium sulfonate (AOS) 5 parts, foam stabilizer nitrilotriacetic acid (SH-193) 2 parts, gelling agent 2 parts, retarder lignosulfonate 3 parts, intumescent flame retardant (IFR) 2 parts, 2 parts of antistatic agent (ASA).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com