Heating assembly for round wire cut-off machine

A technology of heating components and cutting machines, which is applied in the direction of air heaters, fluid heaters, workpiece heating devices, etc., can solve the problems of welding material deformation, less plasticity, and single structure of heating components, so as to prolong the service life and reduce heat energy Divergent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The heating assembly of a round wire cutting machine according to the present invention will be further described in detail through specific embodiments below.

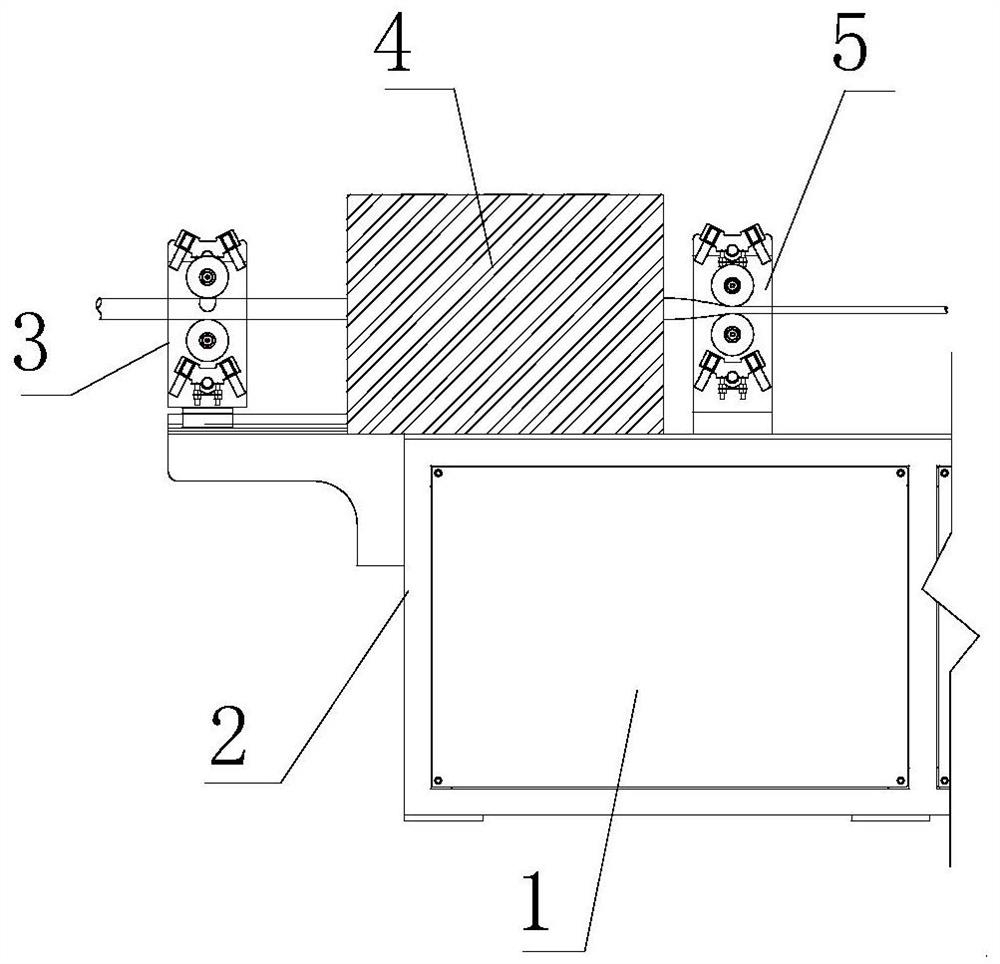

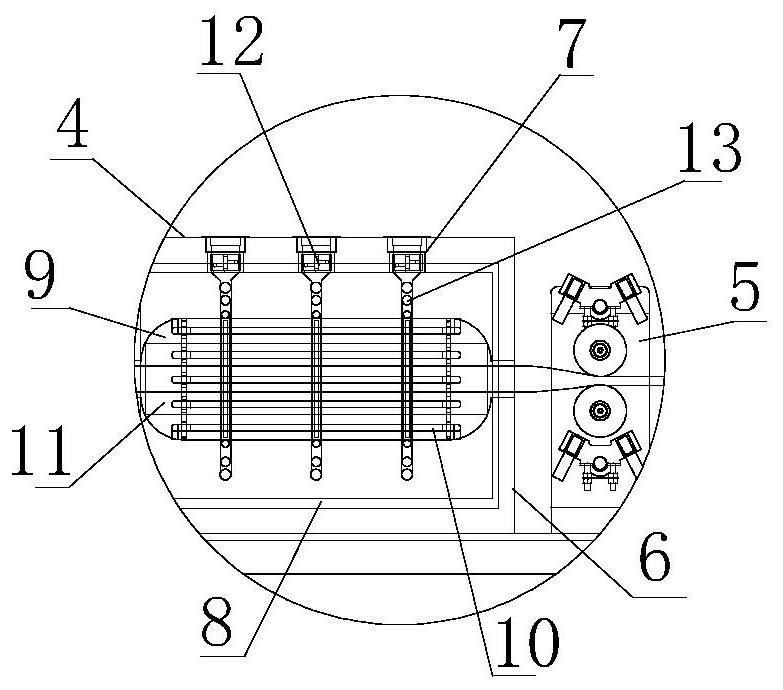

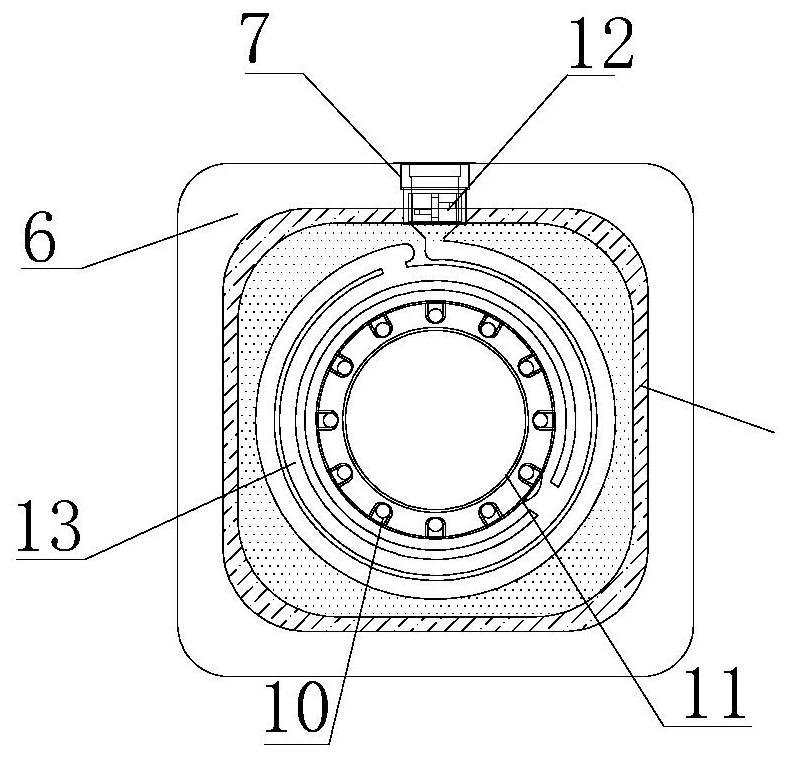

[0018] like Figure 1-3 As shown, the present invention provides a technical solution: a heating assembly of a round wire cutting machine, including a heating assembly body 1, a frame 2, a traction heating group 3, a heating device 4, a calendering heating group 5, a casing 6, a uniform Wind group 7, thermal insulation packing layer 8, inner cavity 9, heating pipe 10, protective net cover 11, blower fan 12, pipe groove 13, heating component body 1 includes frame 2 and the traction device fixed on the frame 2 from left to right The heating group 3, the heating device 4 and the calendering heating group 5, the heating device 4 includes a casing 6 and an even air group 7 embedded in the upper surface of the casing 6, a thermal insulation packing layer 8 is fixed in the wall of the casing 6, and the horizontal dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com