Adjustable bidirectional linkage combined tool

A two-way linkage and combined tool technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve problems such as the inability to quickly remove screws, achieve the effects of enhancing safe operation and safe maintenance, improving power supply reliability, and avoiding irregular operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

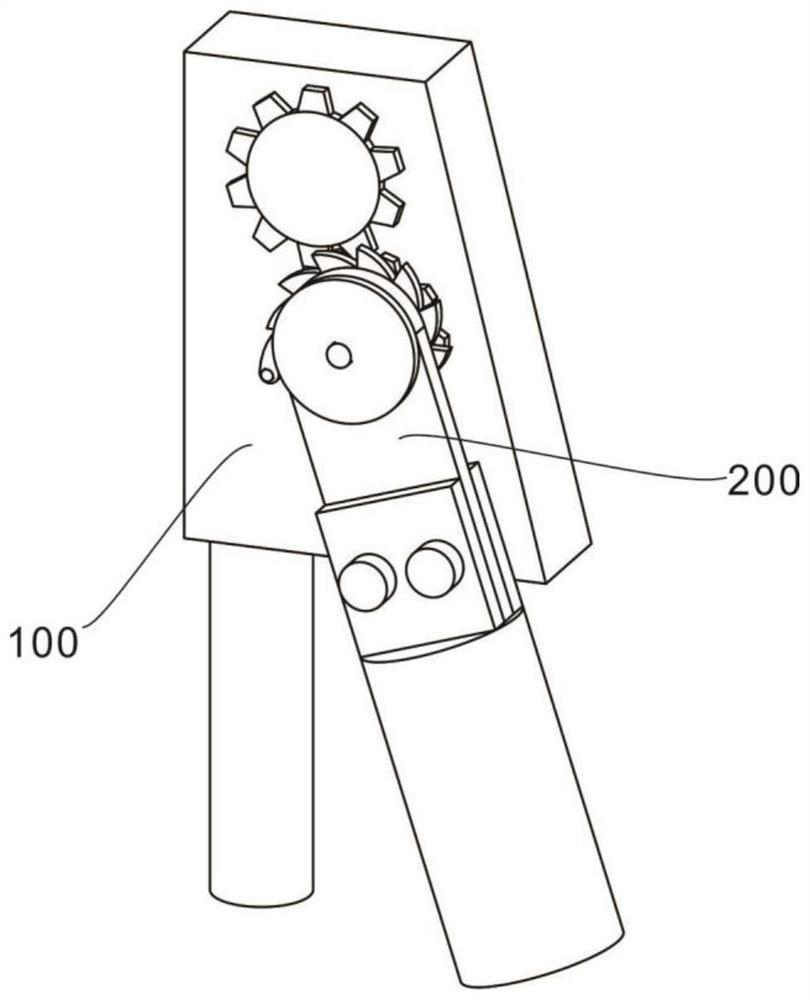

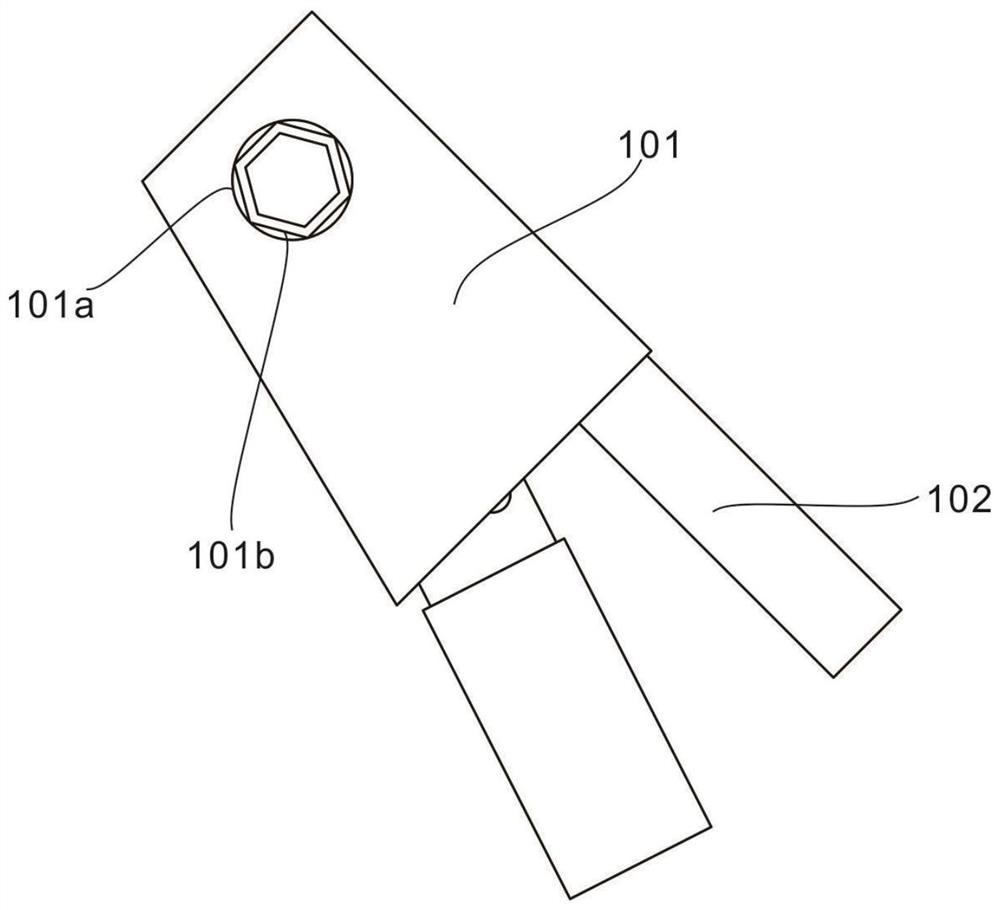

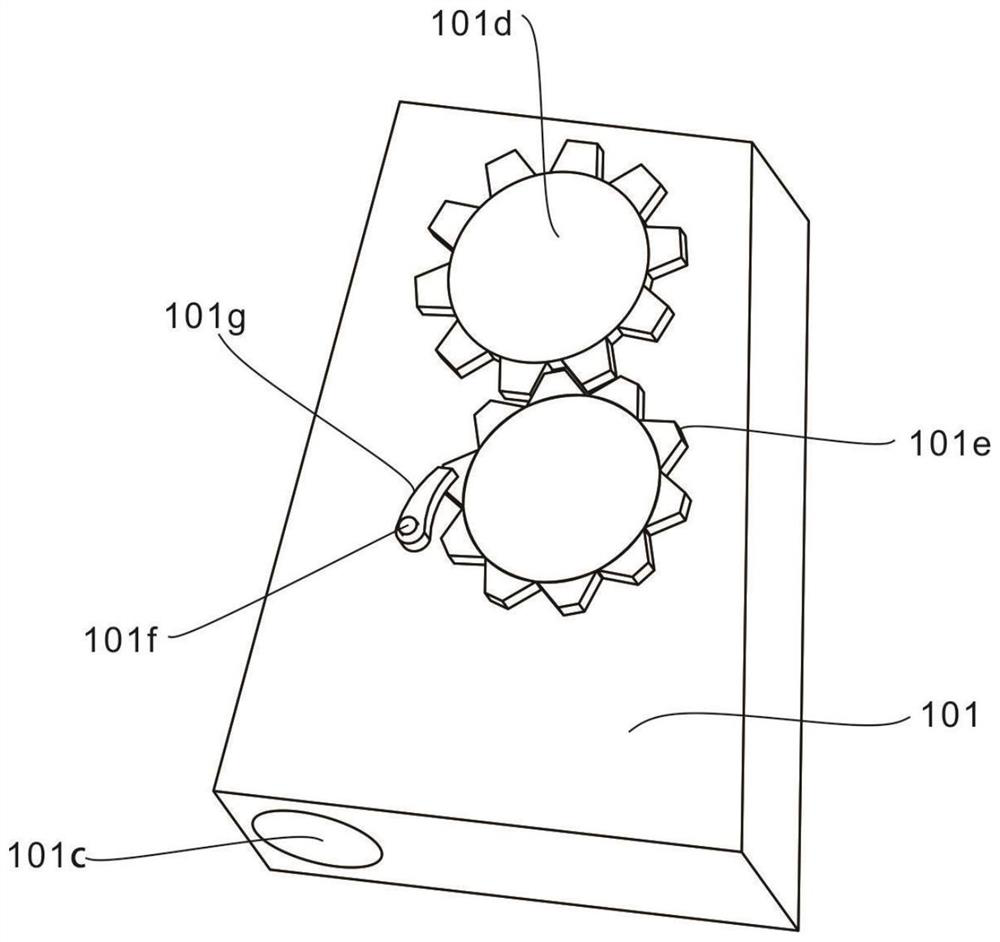

[0028] refer to Figure 1-5 , provides a schematic diagram of the overall structure of an adjustable two-way linkage combination tool, such as Figure 1-5 , an adjustable two-way linkage combination tool includes a card and assembly 100 for limiting the screw, a base 101 for bearing and limiting, a handle 102 for limiting the base 101, and a transmission that provides power for unscrewing the screw. The assembly 200 and the mounting block 201 for carrying and connecting, the limiting hole 101a and the limiting sleeve 101b for limiting the screw, the first threaded hole 101c for connecting the base 101 and the handle 102, and power transmission The first transmission tooth 101d and the second transmission tooth 101e, the first limit rod 101f that limits the brake pawl 101g, and the brake pawl 101g that limits the transmission assembly 200; The limit sleeve 101b located in the limit hole 101a in the component 100 limits the screw, and then the power is provided by the transmiss...

Embodiment 2

[0031] refer to Figure 4-5 , this embodiment is different from the first embodiment in that: the transmission assembly 200 that provides power for unscrewing the screw also includes a rotating shaft 202 that drives the transmission assembly 200 to rotate, drives the card and the second transmission tooth 101e in the assembly 100 to rotate The ratchet 203, the limit block 204 that limits the mounting block 201, the second limit lever 201a that limits the driving pawl 201b, the driving pawl 201b that drives the ratchet 203, and fixes the mounting block 201 The fixing block 205, the second threaded hole 205a and the screw 205b that fix the mounting block 201, and the pressing block 206 that drives the mounting block 201 to rotate, the present invention is located in the limiting hole 101a through the set card and assembly 100. The position sleeve 101b limits the screw, and then presses the pressing block 206 in the transmission assembly 200, so that the pressing block 206 drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com