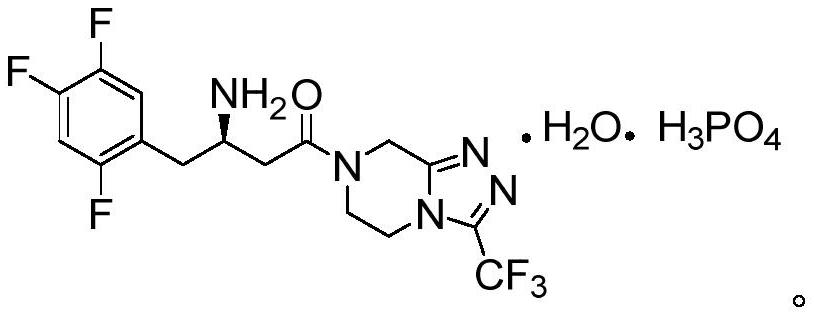

Post-treatment method for preparing sitagliptin by using enzyme method and sitagliptin free alkali

A technology of enzymatic preparation and free alkali, applied in the direction of organic chemistry, can solve the problems of low purity of sitagliptin solution, lack of better post-treatment methods, undisclosed post-treatment procedures, etc., and facilitate commercial production and sales, low cost, and easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Add 6mM HCl to the reaction solution for preparing sitagliptin by enzymatic method to adjust the pH to 1-2 to terminate the reaction, add diatomaceous earth and suction filter to remove the enzyme, and extract the filtrate twice with dichloromethane to remove impurities and unreacted raw materials .

[0052] (2) Use liquid caustic soda to adjust the pH to 7, distill under reduced pressure, steam out 20% of water, and remove dichloromethane dissolved in water.

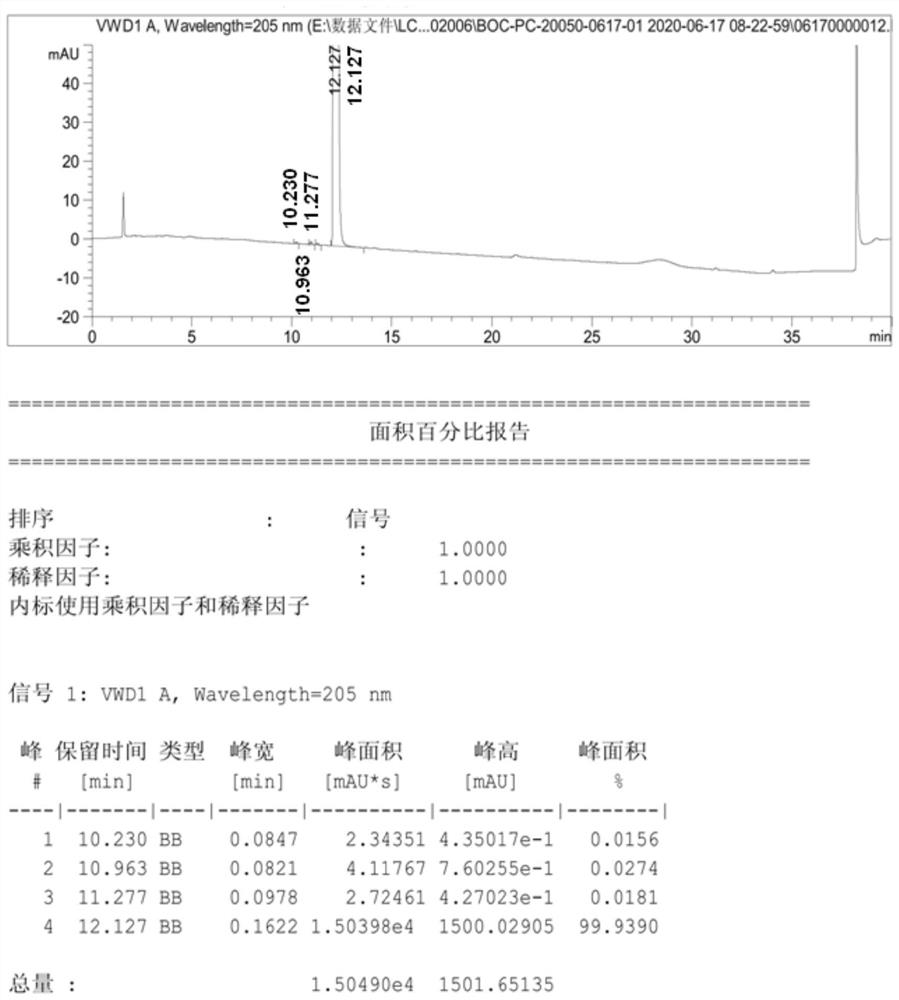

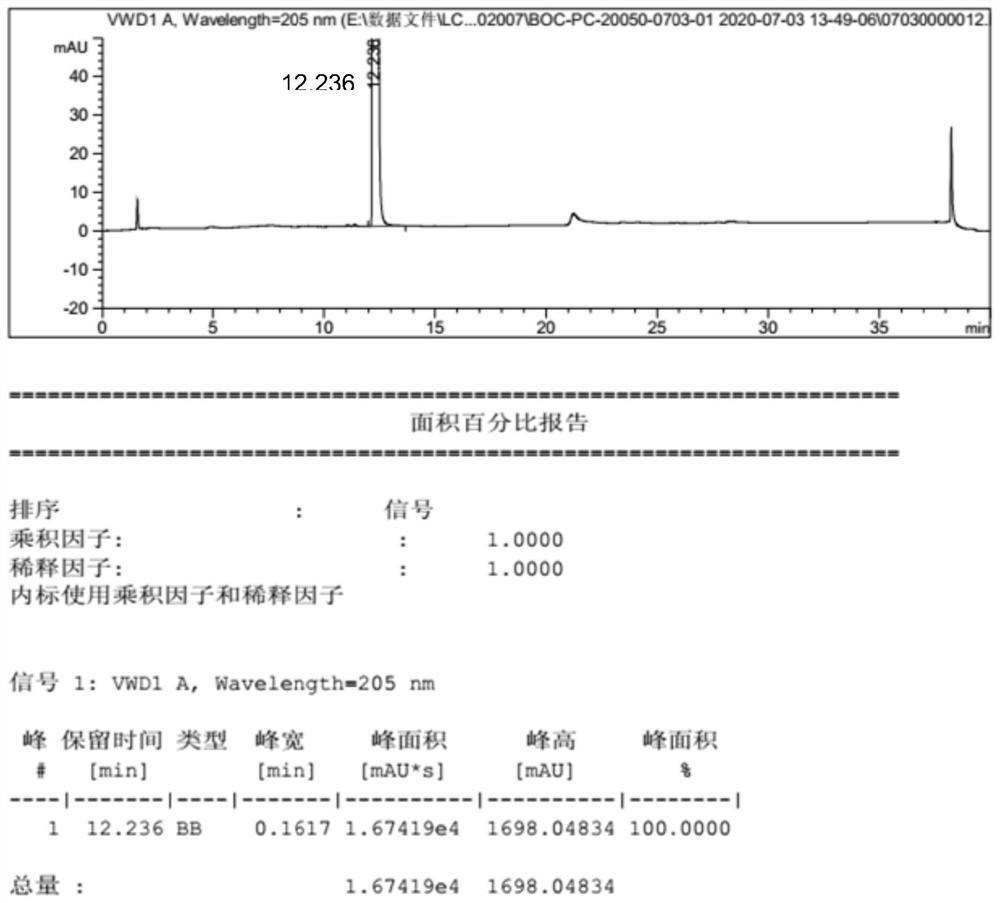

[0053] (3) Cool down to room temperature, adjust the pH to 12 with liquid caustic soda, stir for 16 hours, and after the viscous material is solidified and dispersed, filter with suction and dry at 60° C. for 4 hours to obtain 14.66 g of sitagliptin free base, with a yield of 72%. , 99.5% purity.

Embodiment 2

[0055] (1) Add 6mM HCl to the reaction solution for preparing sitagliptin by enzymatic method to adjust the pH to 1-2 to terminate the reaction, add diatomaceous earth and suction filter to remove the enzyme, and extract the filtrate twice with dichloromethane to remove impurities and unreacted raw materials .

[0056] (2) Use liquid caustic soda to adjust the pH to 7, and perform long-pressure distillation to steam out 30% of water, and remove the dichloromethane dissolved in water.

[0057] (3) Cool down to room temperature, adjust the pH to 12 with liquid caustic soda, stir for 8 hours, and after the viscous material is solidified and dispersed, filter with suction and dry at 70°C for 8 hours to obtain 16.08 g of sitagliptin free base, with a yield of 79%. , 99.6% purity.

Embodiment 3

[0059] (1) Add 6mM HCl to the reaction solution for preparing sitagliptin by enzymatic method to adjust the pH to 1-2 to terminate the reaction, add diatomaceous earth and suction filter to remove the enzyme, and extract the filtrate twice with dichloromethane to remove impurities and unreacted raw materials .

[0060] (2) Use liquid caustic soda to adjust the pH to 7, distill under reduced pressure, steam out 40% of water, and remove dichloromethane dissolved in water.

[0061] (3) Cool down to room temperature, adjust the pH to 12 with liquid caustic soda, stir for 4 hours, and after the viscous material is solidified and dispersed, filter with suction and dry at 60° C. for 4 hours to obtain 17.29 g of sitagliptin free base, with a yield of 85%. , 99.9% purity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com