Structure for crushing meat stuffing

A technology of meat stuffing and mixing drum, which is applied in the direction of meat cutting/trimming, application, processing meat, etc. It can solve the problems of low crushing efficiency, achieve high crushing efficiency, increase the contact area, and improve the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

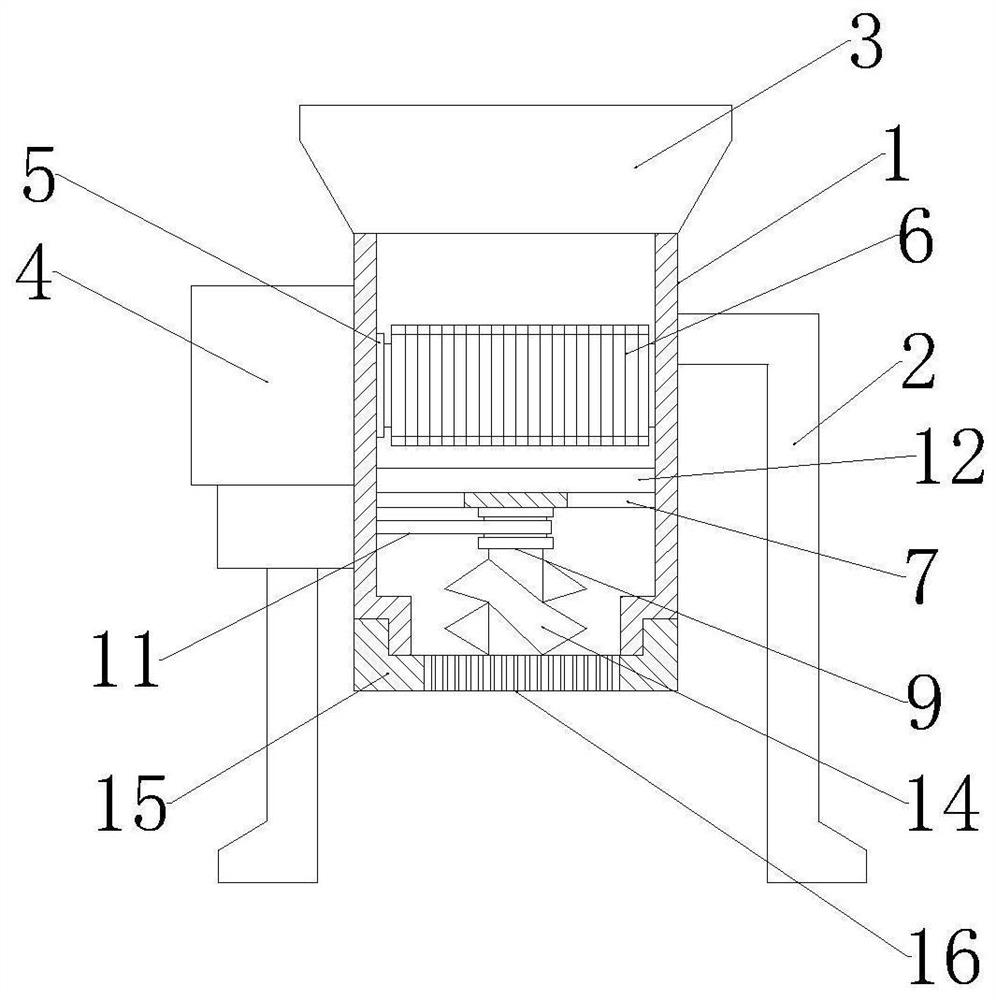

[0030] see Figure 1-4 , the present invention provides the following technical solutions: a structure for minced meat, comprising a mixing drum 1, the outer surface of the mixing drum 1 is fixedly connected with a support leg 2, the top of the mixing drum 1 is fixedly connected with a lower hopper 3, the mixing drum The outer surface of 1 is fixedly connected with a transmission motor 4;

[0031] In this embodiment: the mixing drum 1 is used to store a large amount of raw materials when in use, thereby reducing the number of cutting times, and the supporting legs 2 are used to support the entire device, so as to facilitate the collection of finished meat fillings, and the lower The hopper 3 is used for enlarging the feed inlet, thereby facilitating the placement of raw materials.

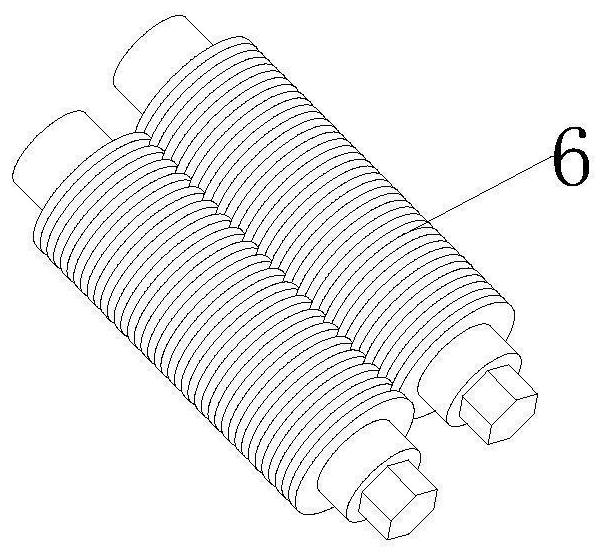

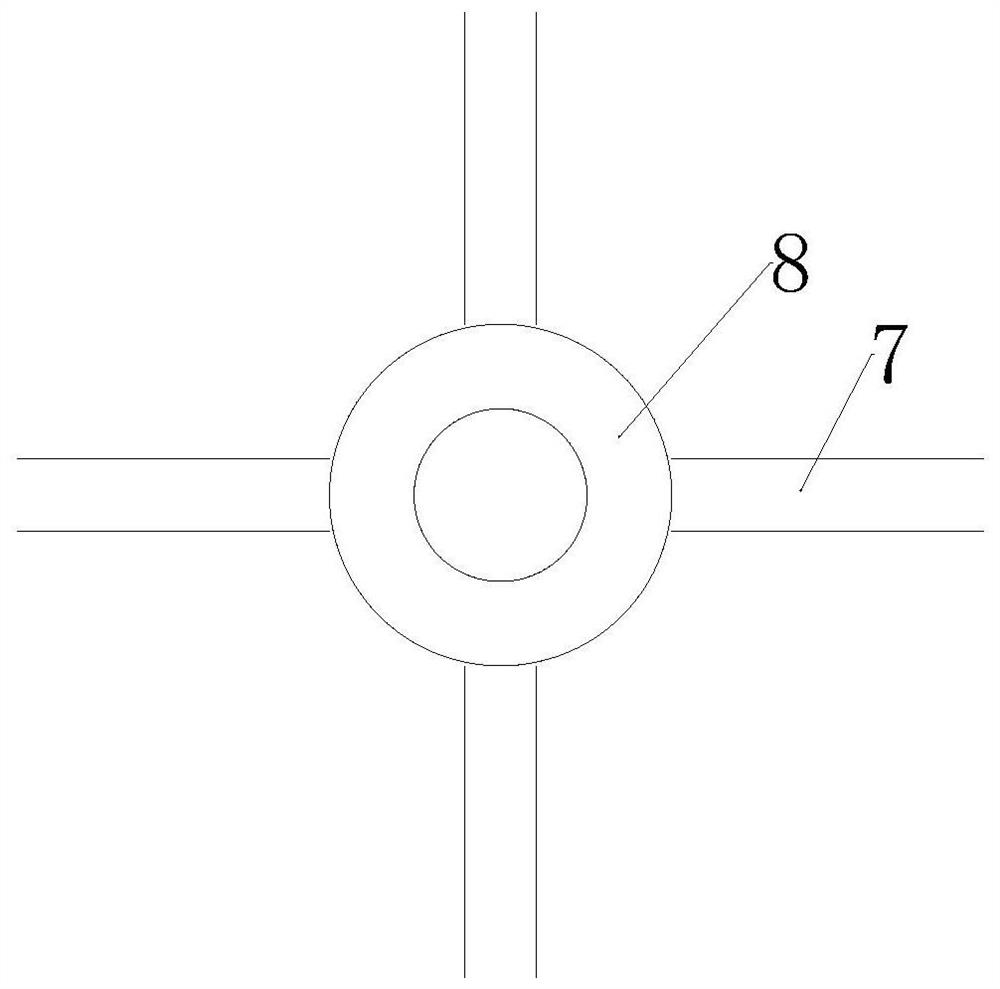

[0032] The inside of the mixing drum 1 is provided with a sealing gasket 5, and the inside of the mixing drum 1 is movably connected with a cutting roller 6;

[0033] In this embodiment: the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com