Spine correction mattress is convenient for clinical nursing

A mattress and spine technology, applied in the field of spine correction mattresses, can solve the problems of short time, deformation of the spine, and discomfort of patients, and achieve scientific structural design, easy acceptance of deformation and curvature, and significant curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

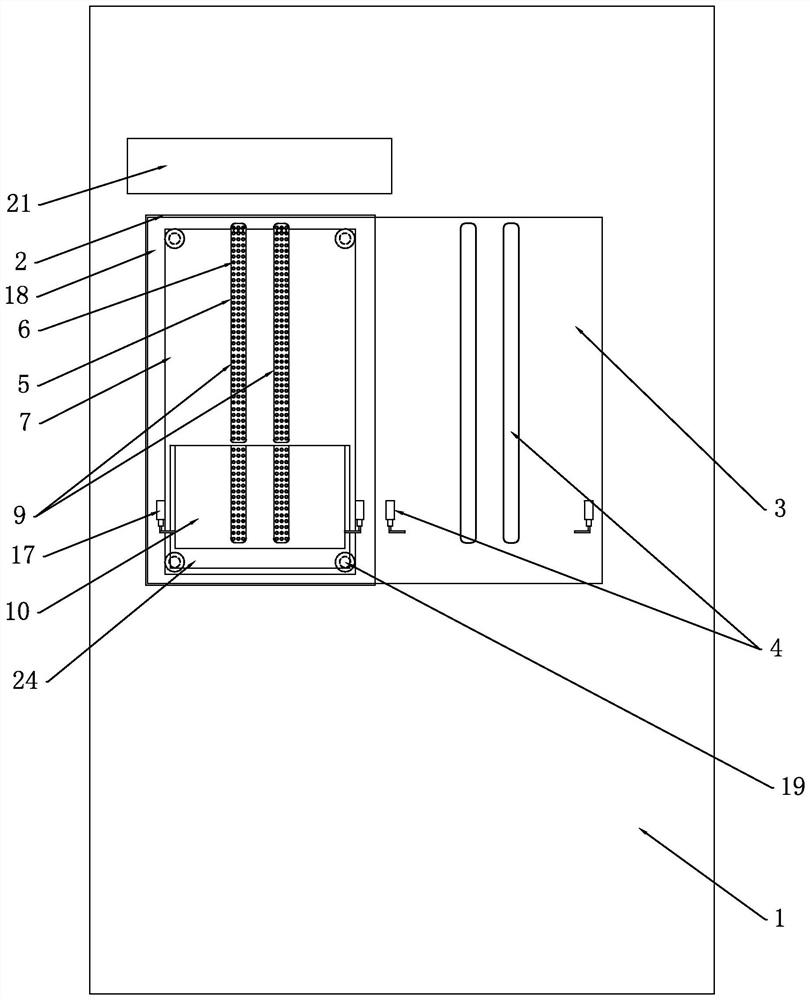

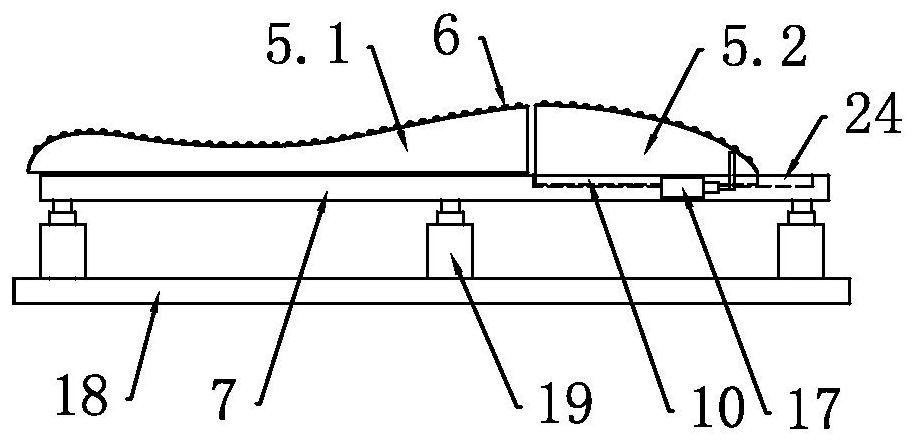

[0044] Such as Figure 1-2 As shown in , 9, the spinal correction mattress that is convenient for clinical nursing use includes a mattress body 1, on which an accommodating cavity 2 and a cover structure 3 that covers the top of the accommodating cavity are arranged; in the accommodating cavity There is a spine posture correction pad structure that can be lifted and adjusted in the cavity; a concave groove 4 matching the top surface of the spine posture correction pad structure is arranged on the inner side of the cover pad structure, and the cover pad structure is connected with the spine posture correction pad through the concave groove. After the posture pad is matched, it is flatly covered with the position of the accommodating cavity of the mattress body, and the cover pad structure 3 is sewn and connected with one side of the mattress body 1, which is convenient to open and close.

[0045] The above-mentioned spine posture correction pad structure includes a curvature co...

Embodiment 2

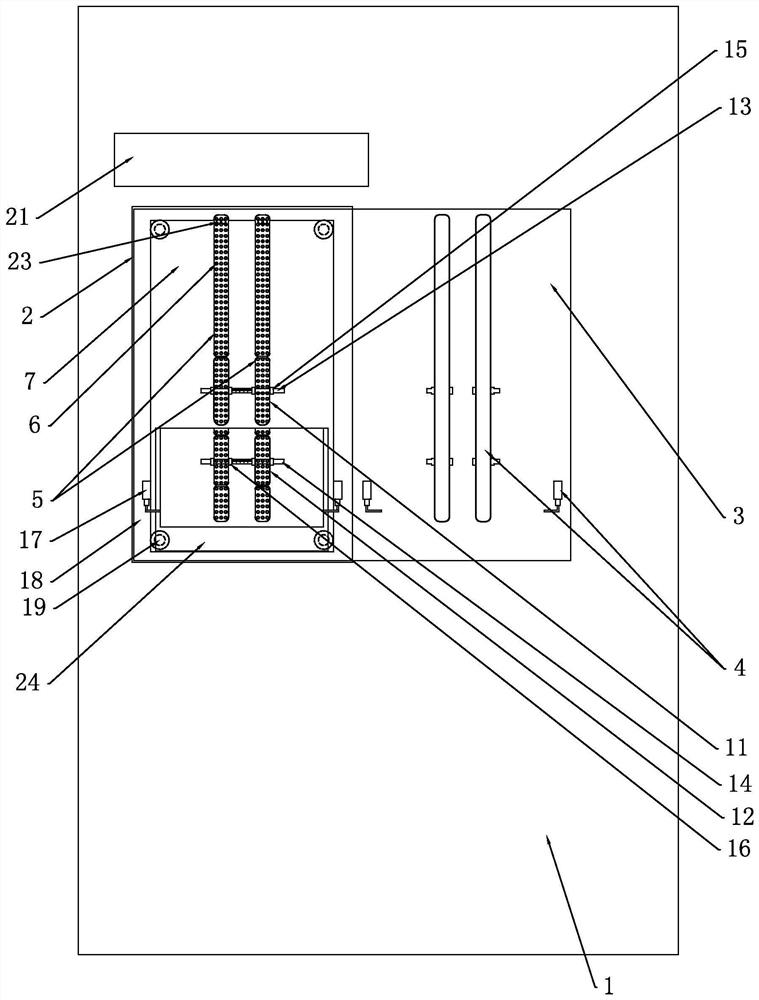

[0056] Such as Figure 3-9 As shown, the orthopedic mattress that is convenient for clinical nursing use includes a mattress body 1, which is provided with an accommodation chamber 2 and a cover structure 3 that covers the top of the accommodation chamber; There is a spine posture correction pad structure that can be adjusted up and down inside; a concave groove 4 matching the top surface of the spine posture correction pad structure is set on the inner side of the cover pad structure, and the cover pad structure is connected to the spine posture correction pad through the concave groove. After matching, it is flatly covered with the position of the accommodating cavity of the mattress body, and the cover pad structure 3 is sewn and connected with one side of the mattress body 1, which is convenient to open and close.

[0057] The above-mentioned spine posture correction pad structure includes a curvature convex seat 5 arranged along the curvature of the human spine, and sever...

Embodiment 3

[0071] Such as Figure 10 As shown, the orthopedic mattress that is convenient for clinical care is the same as the orthopedic mattress in Example 2, the difference is that an accommodating cavity 25 is also provided on the mattress body corresponding to the opened cover structure, and the accommodating cavity 25 is also provided in the accommodating A cushion body 26 is arranged in cooperation with the concave cavity. When in use, the pad body is taken out and used for placing the cover pad structure after opening, so that after the cover pad structure is opened, the flat state of the mattress body outside the accommodation cavity on the mattress body is guaranteed, which is convenient for the patient to move in the accommodation cavity. Lie down on the outer mattress body first, and then move to the position of the accommodating cavity, which can eliminate the inconvenience that may exist during use when the cover pad structure is opened and slightly higher than the mattress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com