Lead-free low-temperature tin-based alloy soldering lug

A technology of tin-based alloys and low-temperature alloys, applied in welding media, welding equipment, metal processing equipment, etc., can solve the problems of poor reliability and low service temperature of solder joints, and achieve the effect of simplifying fusion and reducing the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

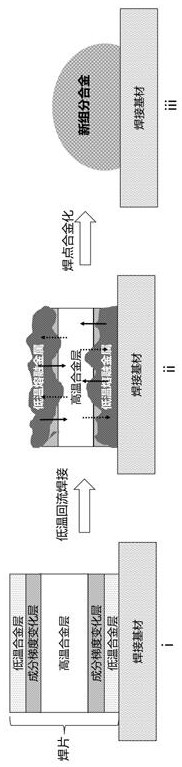

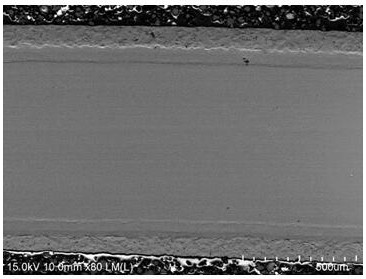

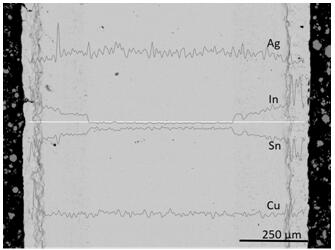

[0031] Embodiment 1: The lead-free tin-based alloy solder sheet in this embodiment consists of five layers of solder sheet, including the middle high-temperature tin-based alloy layer, the composition gradient metal layer located on both sides of the high-temperature tin-based alloy layer, and the composition gradient metal layer located on both sides of the high-temperature tin-based alloy layer. The low-temperature alloy layers on both sides of the layer, among which, the middle high-temperature tin-based alloy layer is Sn-3Ag-0.5Cu, and its solidus temperature is 218.2°C; the low-temperature alloy layer is Sn-52In eutectic alloy, and its solidus temperature is 120.1℃; the total thickness of the solder piece is 1.0 mm, and its structure is as follows figure 2 As shown; the thickness of the high-temperature tin-based alloy layer is 685µm, accounting for 68.5% of the total volume of the solder piece;

[0032] Solid-solid diffusion occurs between the low-temperature Sn-52In eu...

Embodiment 2

[0035] Embodiment 2: The lead-free tin-based alloy solder sheet is composed of five layers of solder sheet, including the middle high-temperature tin-based alloy layer, the composition gradient metal layer located on both sides of the high-temperature tin-based alloy layer, and the composition gradient metal layer located on both sides of the composition gradient change metal layer. The low-temperature alloy layer on the side, in which the middle high-temperature tin-based alloy layer is Sn-3Ag-0.5Cu, and its solidus temperature is 218.2°C; the low-temperature alloy layer on both sides is Sn-52In eutectic alloy, and its solidus temperature is 120.1 ℃; the total thickness of the solder piece is 0.75mm, and its structure is as follows Figure 6 As shown; the thickness of the high-temperature tin-based alloy layer is 504µm, accounting for 67.2% of the total volume of the solder piece;

[0036] The two DSC cycle curves of the solder piece are as follows Figure 7 As shown, the so...

Embodiment 3

[0038] Embodiment 3: The lead-free tin-based alloy solder sheet consists of five layers of solder sheet, including the middle high-temperature tin-based alloy layer, the composition gradient metal layer located on both sides of the high-temperature tin-based alloy layer, and the composition gradient metal layer located on both sides of the composition gradient change metal layer. The low-temperature alloy layer on the side, wherein the middle high-temperature tin-based alloy layer is Sn-0.7Cu, and its solidus temperature is 227.9°C; the low-temperature alloy layer on both sides is Sn-52In eutectic alloy, and its solidus temperature is 120.1°C; The total thickness of the solder tab is 0.75 mm, and its structure is as follows Figure 8 As shown; the thickness of the high-temperature tin-based alloy layer is 409µm, accounting for 54.5% of the total volume of the solder piece;

[0039] The two DSC cycle curves of the solder piece are as follows Figure 9 As shown, the solidus tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solidus temperature | aaaaa | aaaaa |

| Solidus temperature | aaaaa | aaaaa |

| Solidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com