Perovskite quantum dot film and preparation method thereof

A technology of quantum dot film and perovskite, applied in the field of perovskite quantum dot film and its preparation, can solve the problems of unfavorable industrialized production, long preparation process, etc. Effects of Industrialization and Commercialization Prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention provides a method for preparing a perovskite quantum dot film, comprising the following steps:

[0032] S1. Prepare a coating liquid with a fluorine-containing polyolefin and a halide composition; the halide composition includes at least an inorganic halide and at least one organic halide;

[0033] S2, uniformly coating the prepared coating solution on the surface of the substrate to form a wet film coating;

[0034] S3, drying and curing.

[0035] Specifically, the coating solution in step S1 is prepared by the following steps:

[0036] S101. Add the fluorine-containing polyolefin into the first organic solvent according to the first preset mass ratio and stir until completely dissolved to obtain solution A;

[0037] S102. Prepare a halide composition with an inorganic halide and at least one organic halide in a second preset molar ratio;

[0038] adding the halide composition into the second organic solvent, heating and stirr...

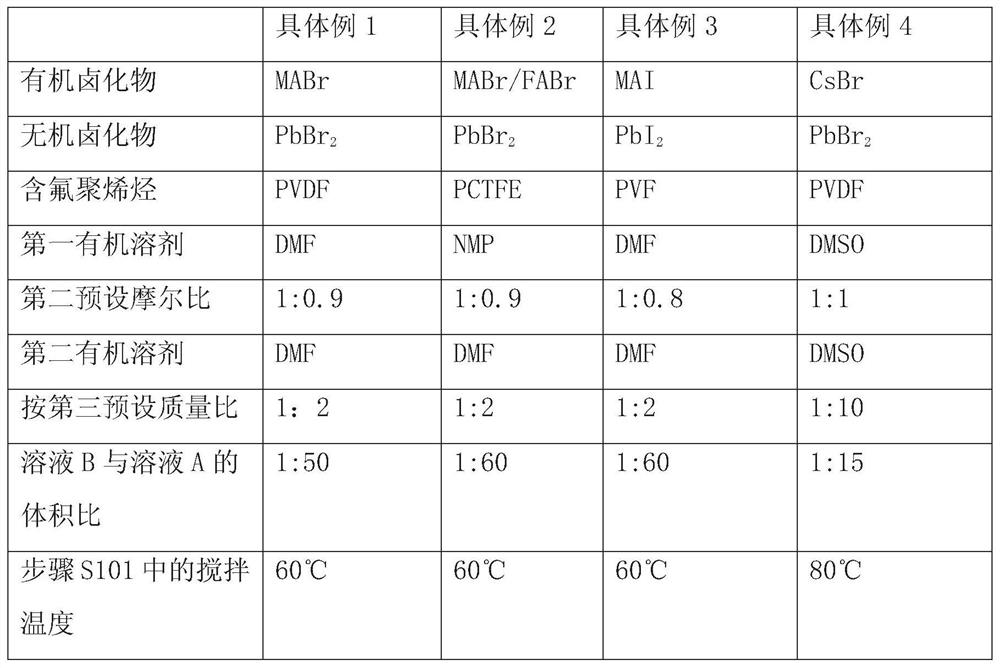

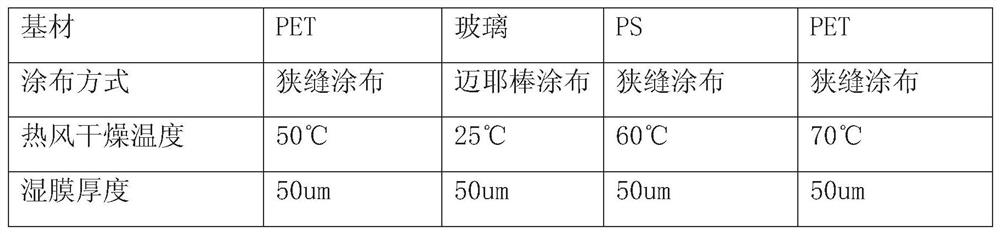

specific example 1-4

[0051]

[0052]

[0053] The present invention has the following beneficial effects:

[0054] 1. The process steps of the preparation method of the perovskite quantum dot film disclosed in the present invention are simple and easy to implement, especially without the need for a vacuum drying process, which greatly reduces the preparation process and reduces the preparation cost;

[0055] 2. The preparation method of the perovskite quantum dot film disclosed in the present invention is more suitable for industrial production and has better industrialization and commercialization prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com