Aromatic hydrogenation catalyst and preparation method thereof

A technology for hydrogenation of aromatics and catalysts, applied in the fields of hydrogenation and refining of aromatics, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of complex preparation process and poor sulfur resistance, Achieve the effects of simple preparation method, strong anti-sulfur poisoning ability, and shortened preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

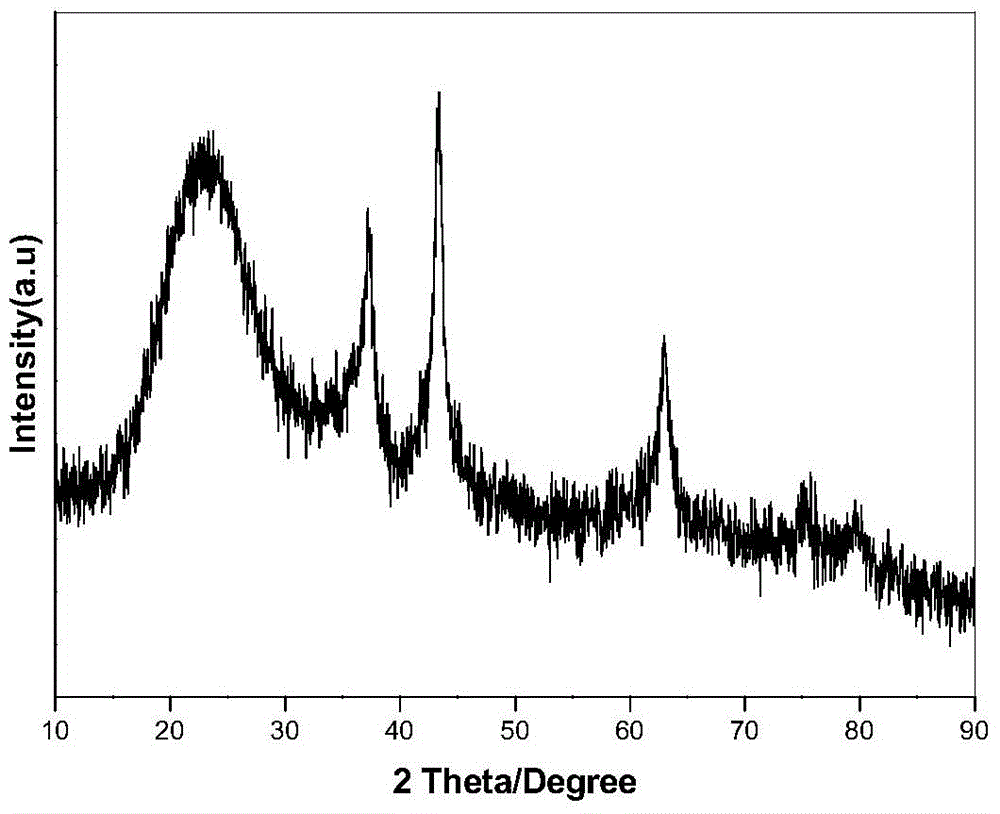

Image

Examples

Embodiment 1

[0041] The preparation process of aromatic hydrocarbon hydrogenation catalyst is as follows:

[0042] 1) according to the proportioning of each component in the catalyst prepared as required, measure 13.5mL of nickel nitrate solution of 1mol / L, 172mL of boric acid solution of 1mol / L, 45mL of tetraethyl orthosilicate solution of 4.4mol / L; Measured 13.5mL nickel nitrate solution, 152mL boric acid solution and 45mL tetraethyl orthosilicate solution were uniformly mixed to obtain the mixed material;

[0043] 2) Stir the mixed material in step 1) at 60°C for 5h, then dry at 110°C for 12h;

[0044] 3) Take the dried solid matter in step 2) and place it in a muffle furnace, heat it up to 400°C at a rate of 10°C / min, and then roast it at a constant temperature for 4 hours;

[0045] 4) Take the roasted solid matter in step 3), mix it with 1g of binder pseudo-boehmite and the remaining 20ml of boric acid solution with a concentration of 1mol / L in step 1), and place it in the muffle In...

Embodiment 2

[0049] The preparation process of aromatic hydrocarbon hydrogenation catalyst is as follows:

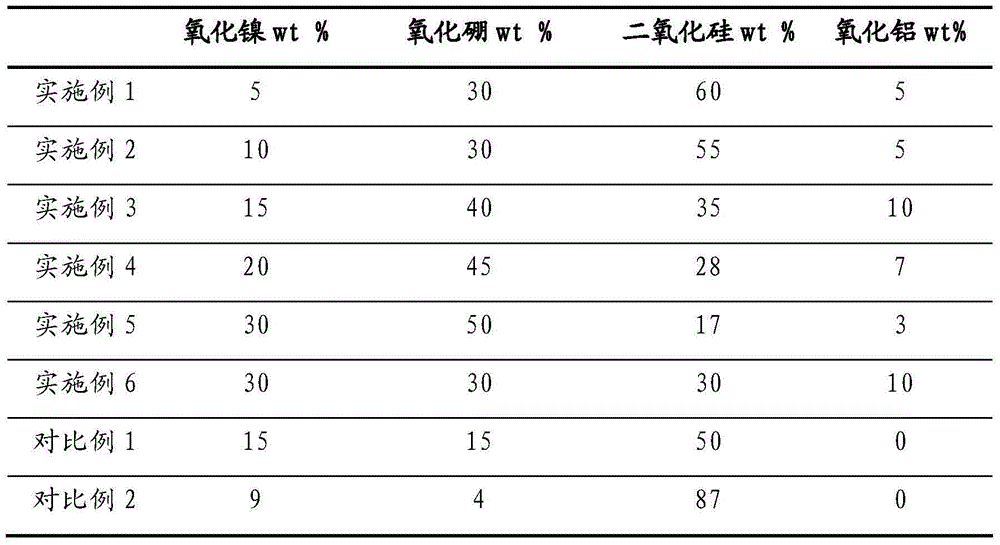

[0050] The difference between embodiment 2 and embodiment 1 is: in step 1), measure the tetraethyl orthosilicate solution of the nickel nitrate solution 33.5mL of 1mol / L, the boric acid solution 360mL of 1mol / L, 4.4mol / L 52mL; the measured 33.5mL nickel nitrate solution, 225mL boric acid solution and 52mL tetraethyl orthosilicate solution are uniformly mixed to obtain a mixed material; in step 4), the solid matter after roasting in step 3) is mixed with 1g of After the boric acid solution of 1mol / L is mixed in the remaining 135ml concentration of binder pseudo-boehmite and step 1), it is placed in a muffle furnace for roasting; all the other are with embodiment 1, and the content of each component of the catalyst obtained is as follows: Table 1 shows.

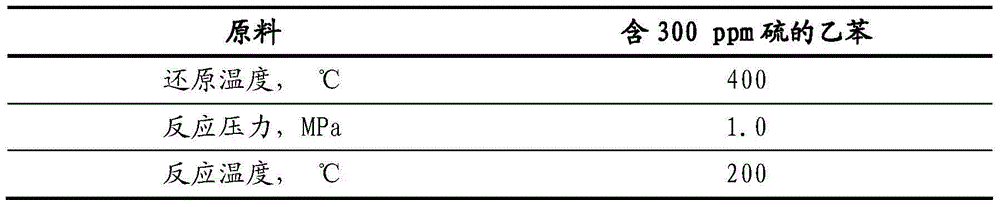

[0051] The activity evaluation process of the obtained aromatic hydrocarbon hydrogenation catalyst is the same as in Example 1, and...

Embodiment 3

[0053] The preparation process of aromatic hydrocarbon hydrogenation catalyst is as follows:

[0054] The difference between embodiment 3 and embodiment 1 is: in step 1), measure 80 mL of nickel nitrate solution of 1 mol / L, 460 mL of boric acid solution of 1 mol / L, 53 mL of tetraethyl orthosilicate solution of 4.4 mol / L ; 80mL nickel nitrate solution, 300mL boric acid solution and 53mL tetraethyl orthosilicate solution are uniformly mixed to obtain the mixed material; in step 4), the solid matter after roasting in step 3) is bonded with 4g Remaining 160ml concentration in the agent pseudo-boehmite and step 1) is after the boric acid solution of 1mol / L mixes, and is placed in the muffle furnace to roast; All the other are with embodiment 1, and the content of each component of the catalyzer that obtains is as table 1 shown.

[0055] The activity evaluation process of the obtained aromatic hydrocarbon hydrogenation catalyst is the same as in Example 1, and the reaction results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com