A kind of composite material battery box manufacturing process

A manufacturing process and composite material technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of restricting the application of metal bushing forming methods, increasing the size and weight of metal bushings, and low heating efficiency of materials. Achieve the effects of shortening the cycle time of curing and molding, ensuring product structure design, and high process feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the above-mentioned features and advantages of the present invention easier to understand, the following specific embodiments are given and the accompanying drawings are described in detail as follows, but the present invention is not limited thereto.

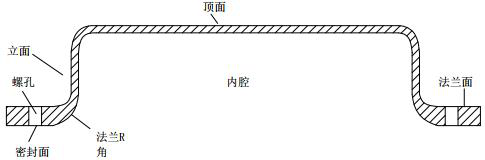

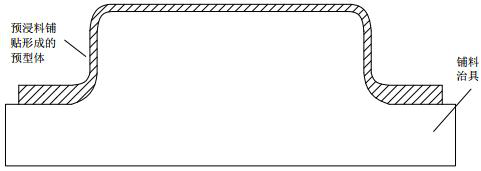

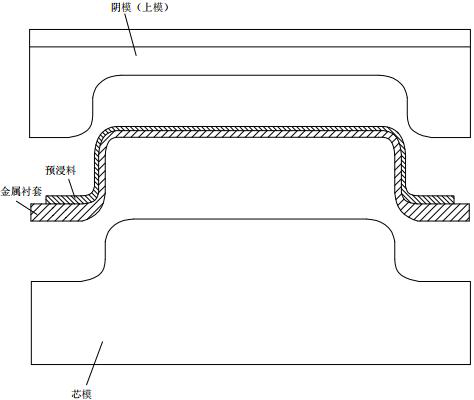

[0056] Generally, in order to meet the structural design requirements, the prepreg used in the PCM battery box can be designed with large fabrics, surrounding flanges and flange thickening materials with thickened R corners, and the R corners of the facade are reinforced. materials, and other materials with structural design significance. Taking the PCM battery box with the flange thickness of about 2.5mm, the R angle thickness of the facade about 1.6mm, and the thickness of the remaining parts about 0.9mm as an example, the prepreg sheet with a glass fiber surface density of 400gsm and a resin content of about 40% is used. When it is used, the large fabric is 3-layer material, the flange thickening mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com