Drying temporary storage machine

A caching machine and drying technology, which is applied in the direction of conveyor objects, conveyor control devices, pretreatment surfaces, etc., can solve the problems of long length of double-speed chain conveyor line, large site occupation area, and slow speed, so as to save floor space , Guaranteed output, extended motion stroke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

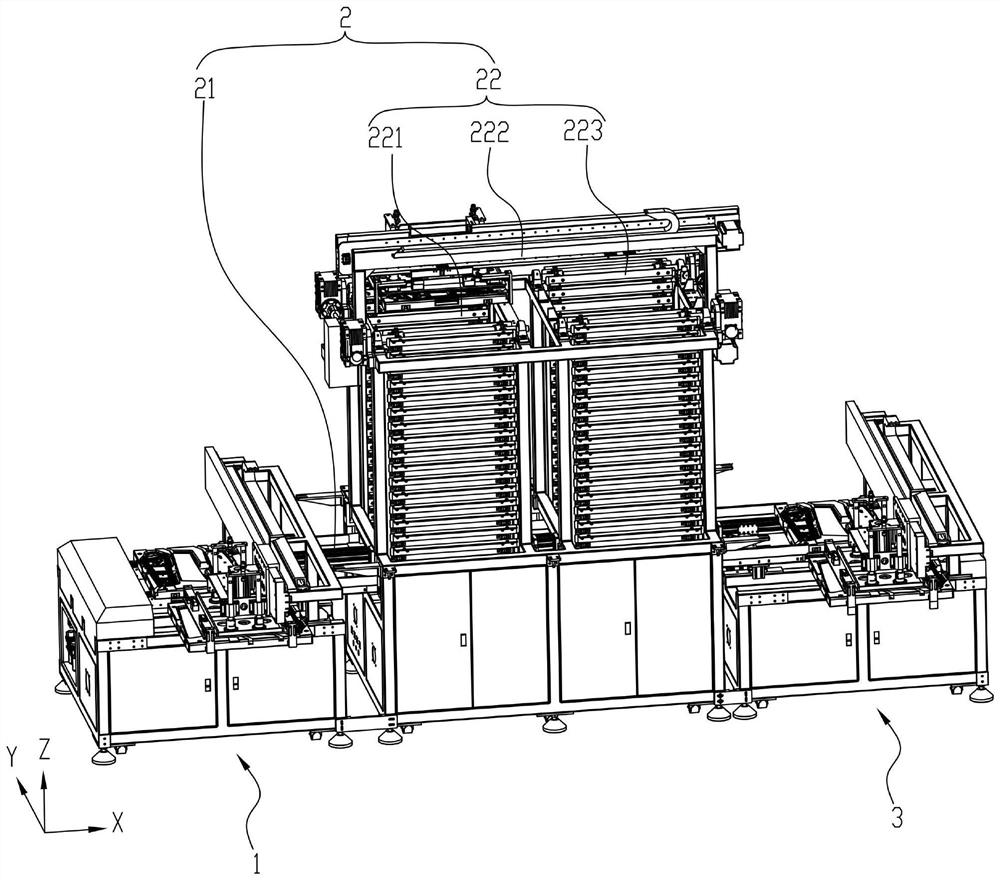

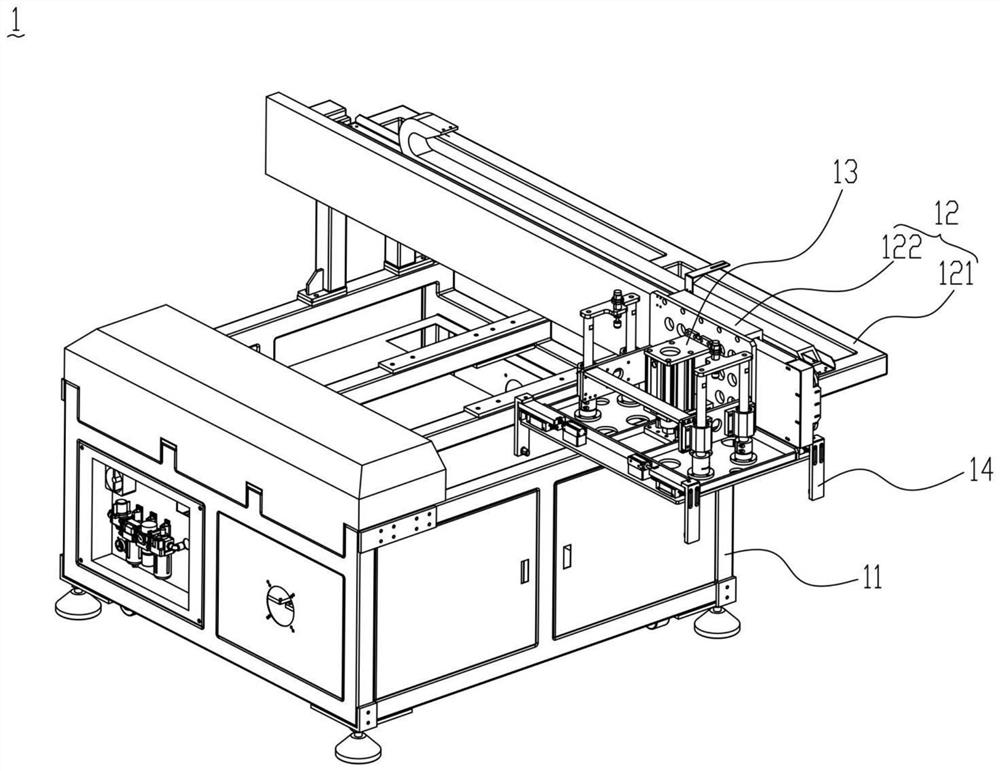

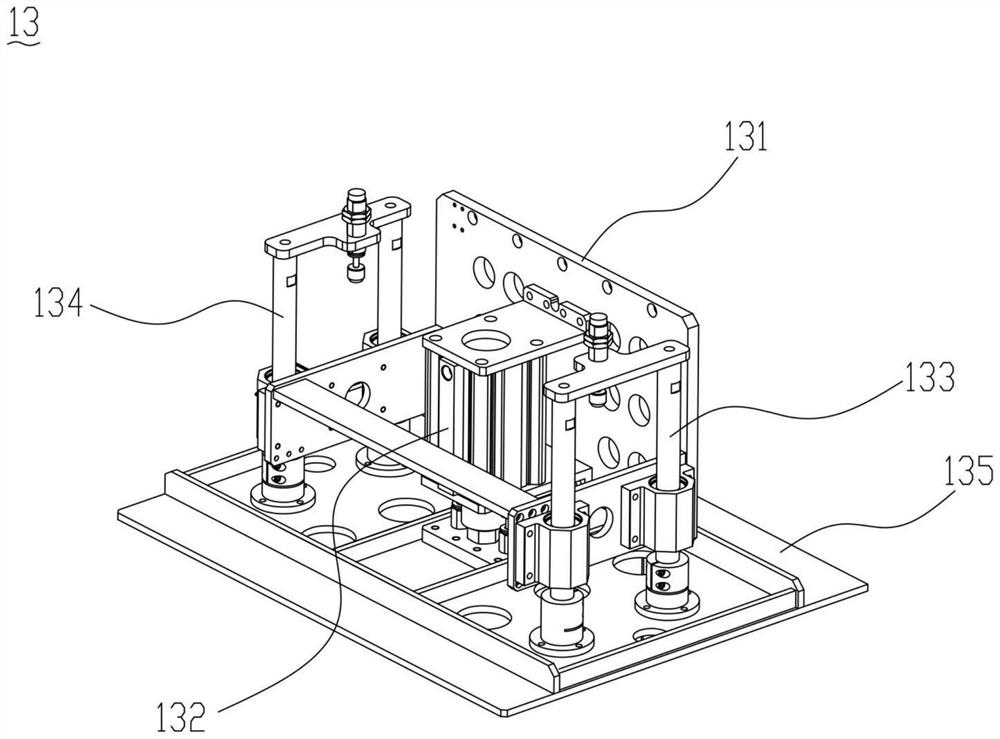

[0022] Please refer to figure 1 , a drying cache machine, including a feeding device 1, a natural air-drying device 2 and a feeding device 3, the natural air-drying device 2 is located between the feeding device 1 and the unloading device 3, and the natural air-drying device 2 is arrayed along the X-axis First, the natural air-drying equipment 2 includes an X-axis conveying device 21 and a vertical trajectory conveying device 22. The vertical trajectory conveying device 22 is arranged on the X-axial conveying device 21. The material mechanism 222 and the circulating lowering mechanism 223, the circulating lifting mechanism 221 and the circulating lowering mechanism 223 are successively arranged on the X-axis conveying device 21 along the conveying direction of the X-axis conveying device 21, and the material-transporting mechanism 222 is arranged across the X-axis On the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap