Preparation method of 2, 7-naphthalene disulfonic acid

A technology of naphthalene disulfonic acid and acidity, applied in the preparation of sulfonic acid, organic chemistry, etc., can solve the problems of low naphthalene utilization rate, low conversion rate, increased reaction cost, etc., and achieves improved conversion rate, improved purity, and high utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

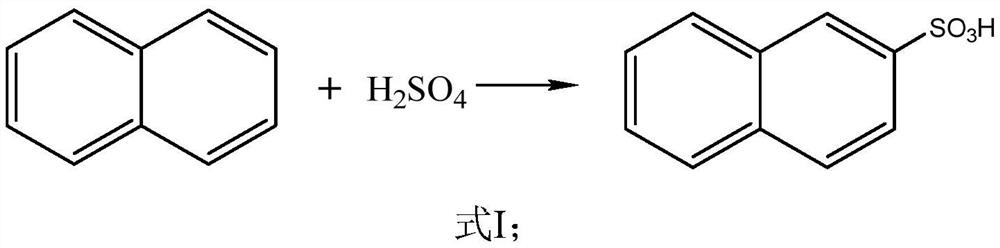

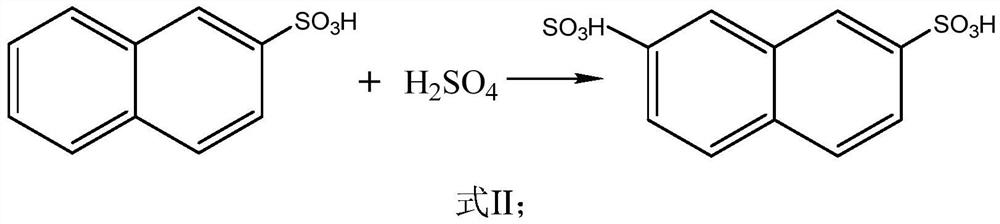

Method used

Image

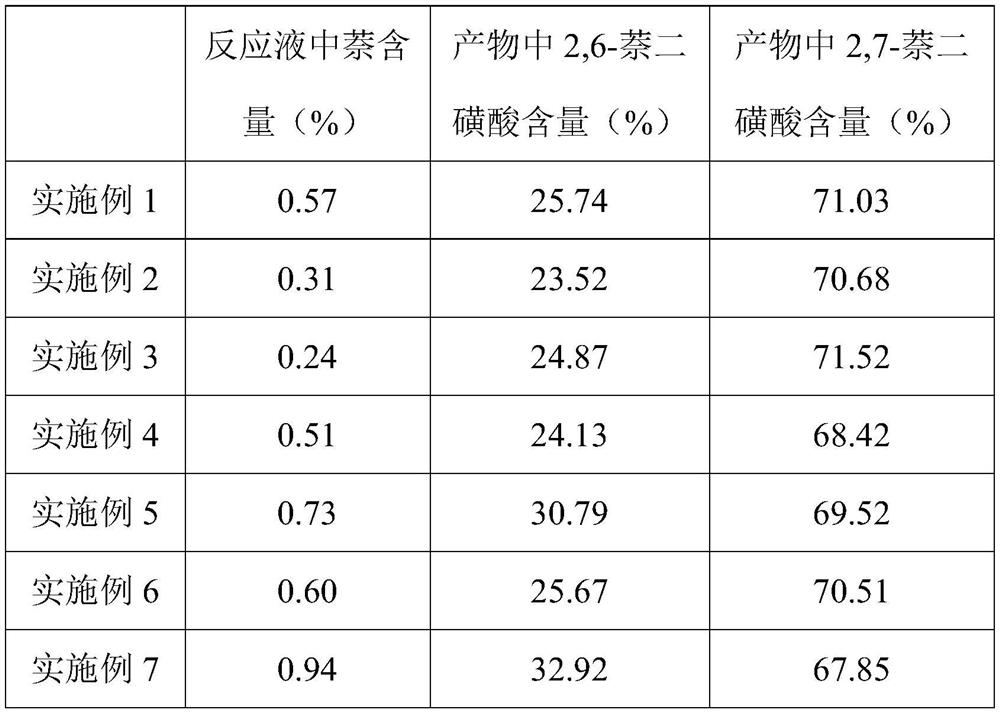

Examples

Embodiment 1

[0037] A kind of preparation method of 2,7-naphthalene disulfonic acid, specifically comprises the steps:

[0038] (1) Heating 1 mol of industrial naphthalene to 80° C., and after all of them melted, slowly added 1.15 mol of concentrated sulfuric acid with a concentration of 98%, raised the temperature to 90° C. under nitrogen protection conditions, and reacted for 150 minutes to obtain an intermediate product;

[0039] (2) Add 2 mol of concentrated sulfuric acid with a concentration of 98% to the intermediate product obtained in step (1), vacuumize, so that the negative pressure of the reaction is 10Pa, heat up to 135 ° C, after reacting for 6 hours, cool to 50 ° C, add water to control The acidity is 50 mgKOH / g, dissolved and filtered to obtain the 2,7-naphthalene disulfonic acid.

Embodiment 2

[0041] A preparation method of 2,7-naphthalene disulfonic acid, the only difference from Example 1 is that the concentration of 98% concentrated sulfuric acid in step (1) is added in an amount of 1.3mol, other components, consumption and process The parameters were all the same as in Example 1 to obtain the 2,7-naphthalene disulfonic acid.

Embodiment 3

[0043] A preparation method of 2,7-naphthalene disulfonic acid, the only difference from Example 1 is that the concentration of 98% concentrated sulfuric acid in step (1) is added in an amount of 1.55mol, other components, consumption and process The parameters were all the same as in Example 1 to obtain the 2,7-naphthalene disulfonic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com