Alloy material for petroleum valve rod and preparation method thereof

A technology of alloy materials and valve stems, which is applied in the field of alloy materials for petroleum valve stems and its preparation, can solve problems such as short service life, corrosion cracking, etc., and achieve the effects of prolonging service life, enhancing corrosion resistance, and reducing impurity inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

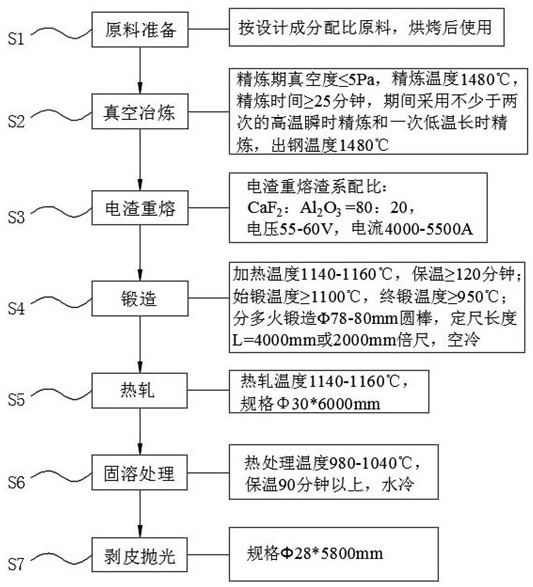

[0025] See figure 1 According to another aspect of the present invention, a method for preparing an alloy material for a petroleum valve stem is also provided, comprising the following steps:

[0026] Step S1: Raw material preparation: Proportion the raw materials according to the designed composition, polish the surface of all raw materials, and use them after baking; among them, the raw material nickel plate needs to be baked at 780°C for more than 4 hours. The dosing process needs to strictly control the dosing range of each element to ensure that the control of easily burnt elements is qualified during the electroslag remelting process and avoid the introduction of harmful elements. The operation of polishing the surface of raw materials can remove the oxide film or impurities on the surface of each raw material; baking each raw material can reduce the gas brought in during smelting, improve the purity of the alloy, and improve the overall performance of the alloy.

[002...

Embodiment 1

[0036] The chemical composition of an alloy material for a petroleum valve stem according to Example 1 of the present invention is: C: 0.04%, Si: 0.30%, Mn: 0.25%, P: 0.008%, S: 0.005%, Al: 0.60 %, B: 0.004%, Cr: 19.20%, Mo: 3.05%, Ni: 52.50%, Nb+Ta: 5.10%, Ti: 0.95%, Pb: 0.001%, Bi: 0.0001%, Ag: 0.0004%, Ca : 0.01%, Mg: 0.01%, Cu: 0.15%, Co: 0.90%, and the balance is Fe and unavoidable impurities.

[0037] The preparation method of a kind of alloy material for petroleum valve rod of embodiment 1 of the present invention comprises the following steps:

[0038] Step S1: Raw material preparation: Proportion the raw materials according to the designed composition, polish the surface of all raw materials, and use them after baking; among them, the raw material nickel plate needs to be baked at 780°C for more than 4 hours.

[0039] Step S2: Vacuum smelting: the raw materials are loaded into the furnace, and the furnace loading sequence is as follows: pure iron blocks and nickel bl...

Embodiment 2

[0046] The chemical composition of an alloy material for a petroleum valve stem according to Example 2 of the present invention is: C: 0.05%, Si: 0.28%, Mn: 0.30%, P: 0.010%, S: 0.008%, Al: 0.50 %, B: 0.005%, Cr: 19.50%, Mo: 3.10%, Ni: 52.0%, Nb+Ta: 5.20%, Ti: 1.05%, Pb: 0.001%, Bi: 0.0001%, Ag: 0.0005%, Ca : 0.008%, Mg: 0.008%, Cu: 0.20%, Co: 0.80%, and the balance is Fe and unavoidable impurities.

[0047] The preparation method of a kind of alloy material for petroleum valve rod of embodiment 2 of the present invention comprises the following steps:

[0048] Step S1: Raw material preparation: Proportion the raw materials according to the designed composition, polish the surface of all raw materials, and use them after baking; among them, the raw material nickel plate needs to be baked at 780°C for more than 4 hours.

[0049] Step S2: Vacuum smelting: the raw materials are loaded into the furnace, and the furnace loading sequence is as follows: pure iron blocks and nickel b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com