Fabricated steel-concrete combined rigid frame bridge and construction method thereof

A prefabricated, rigid-frame bridge technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of increasing the traffic interference of the lower roads, increasing the investment of construction units, and increasing the workload on site, so as to reduce the Use less steel, improve aesthetics, and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

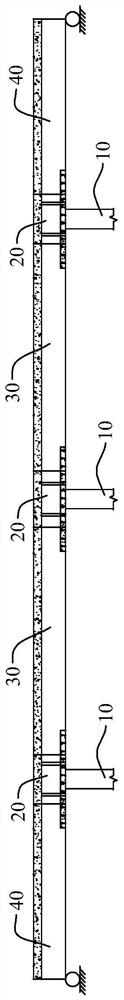

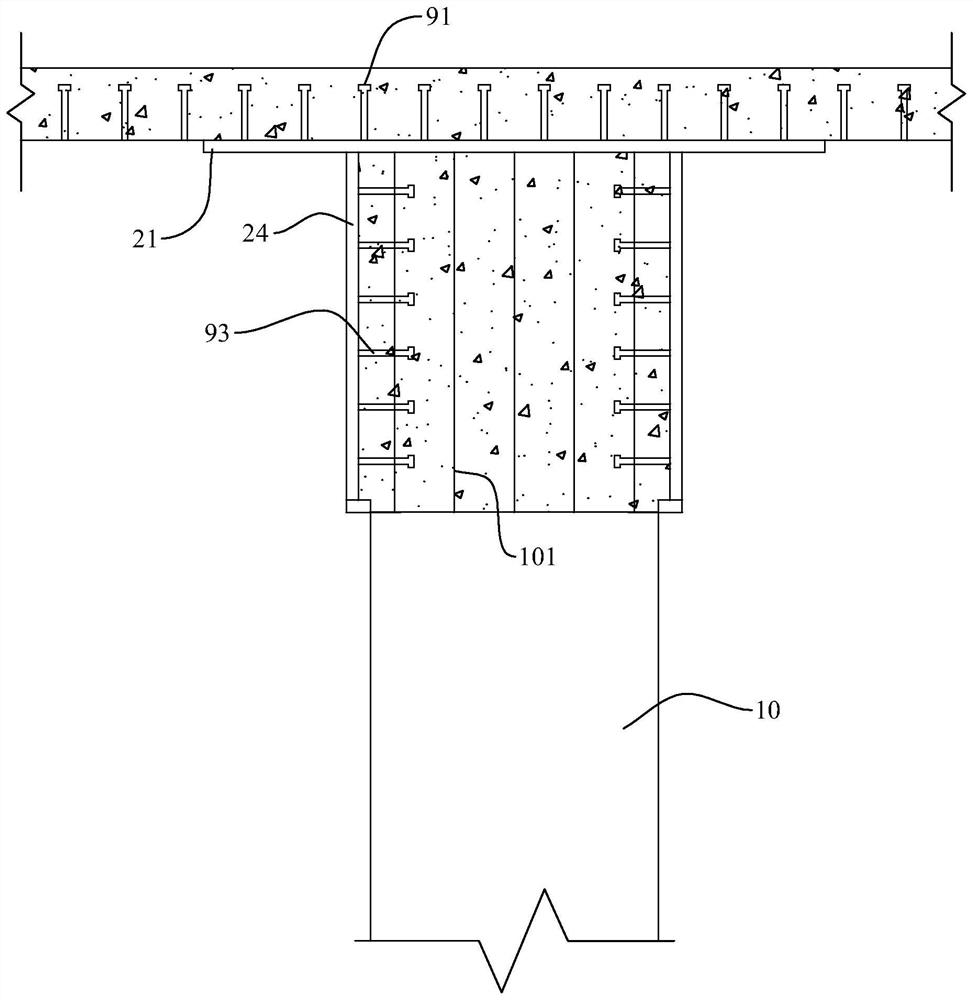

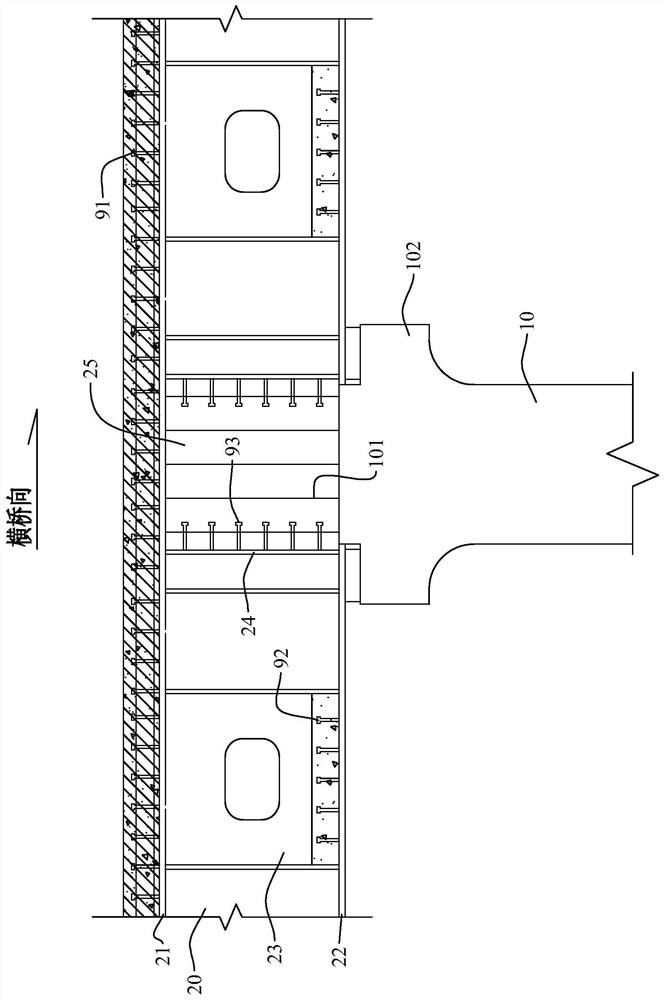

[0036] refer to Figure 1 to Figure 8 , the embodiment of the present invention provides an assembled steel-concrete composite rigid frame bridge, the assembled steel-concrete composite rigid frame bridge includes several prefabricated main girder segments, pier columns 10, prefabricated beams 20, longitudinal connecting sections 50 and transverse connecting sections 60.

[0037]The prefabricated main beam section can be divided into a prefabricated end section 40 and a prefabricated middle beam section 30 , and the prefabricated main beam section is mainly composed of steel beams, concrete slabs and several roof shear connectors 91 . The concrete slab is located above the top slab 21, and one end of the top slab shear connector 91 is welded on the top slab 21, and the other end is integrated with the main beam after pouring the concrete slab. The steel girder is mainly composed of a top plate 21, a bottom plate 22 and two web plates 23 welded together.

[0038] At the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com