Thermally driven resonant micropump

A thermally driven and resonant technology, applied in the direction of variable displacement pump components, pumps with flexible working elements, pumps, etc., can solve the problems of high cost, high processing difficulty, difficult to prepare piezoelectric materials, etc., to reduce processing costs, Optimizing the machining process, the effect of constant fluid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

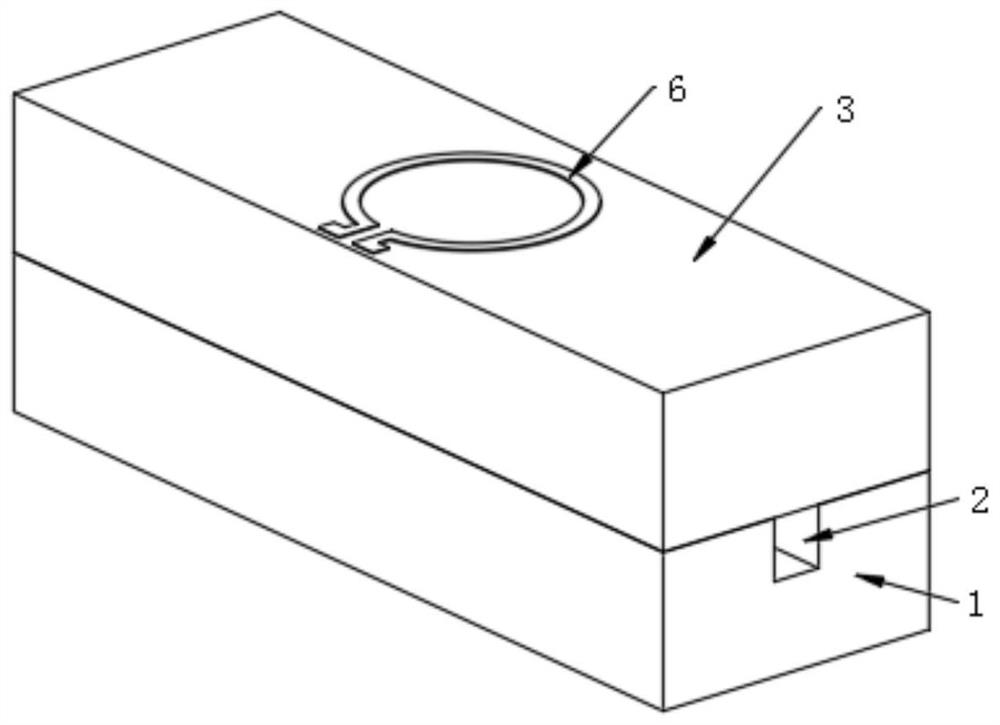

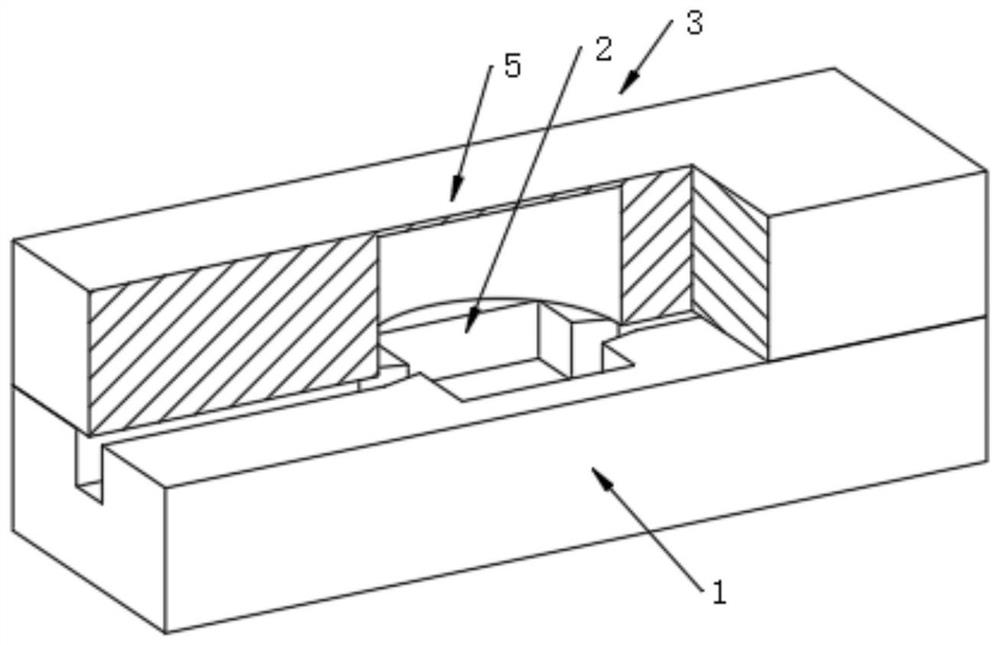

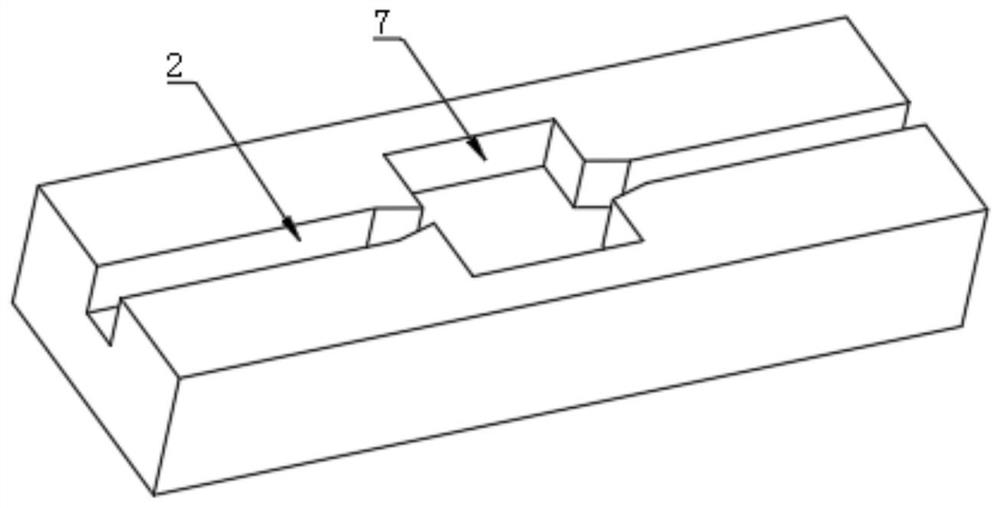

[0030] EXAMPLES: A thermally driven resonant micropump, such as figure 1 with figure 2 As shown, including the substrate 1, the upper surface of the substrate 1 is provided with the flow path 2 for the microfluid through the microfluid, and the substrate 1 is provided with a cover 3 for the closure flow path 2, and passed over the block 3 Eroching forming cavity 4, cavity 4 communication passage 2, unclosed substrate 1 of the cavity 4 above the upper surface of the diaphragm 5, the upper surface of the diaphragm 5 is provided with a hot wire 6, the thickness of the diaphragm 5 is 10 -200um.

[0031] When the microfluid is passed through the flow path 2, the cycle voltage is applied to the electric wire 6 with a frequency F0, and the heat transfer output of the frequency F0 generates the frequency F0, the diaphragm 5 is heat-generating periodic thermal stress of the frequency F0, when the thermal stress When the frequency F0 is close to the inherent frequency f1 of the vibrating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com