A high-speed centrifugal pump with built-in impeller

A high-speed centrifugal, built-in technology, applied in the field of centrifugal pumps, to achieve the effect of improving anti-cavitation performance, light motor, and short axial distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

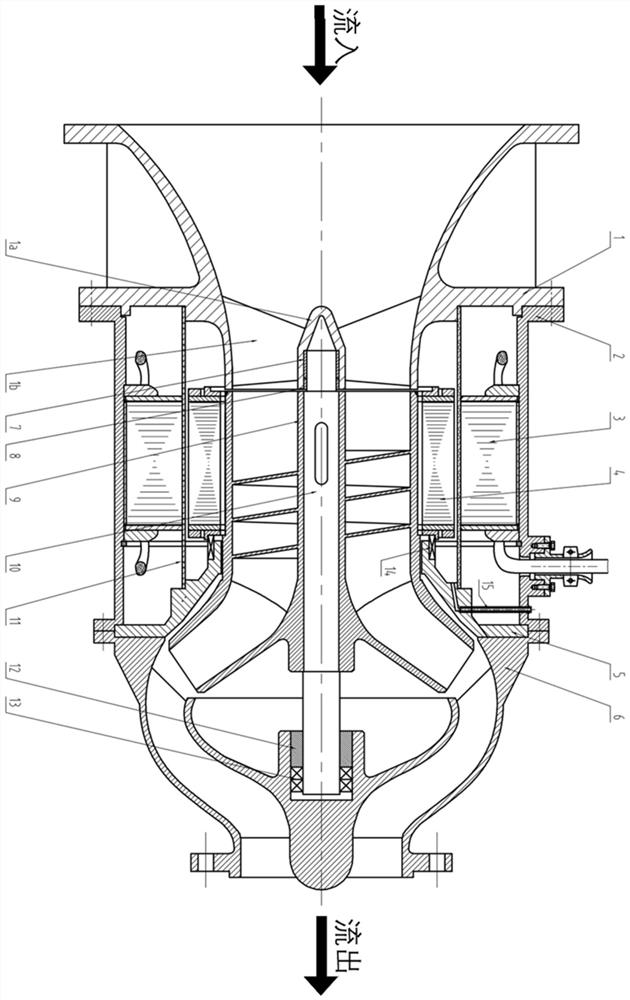

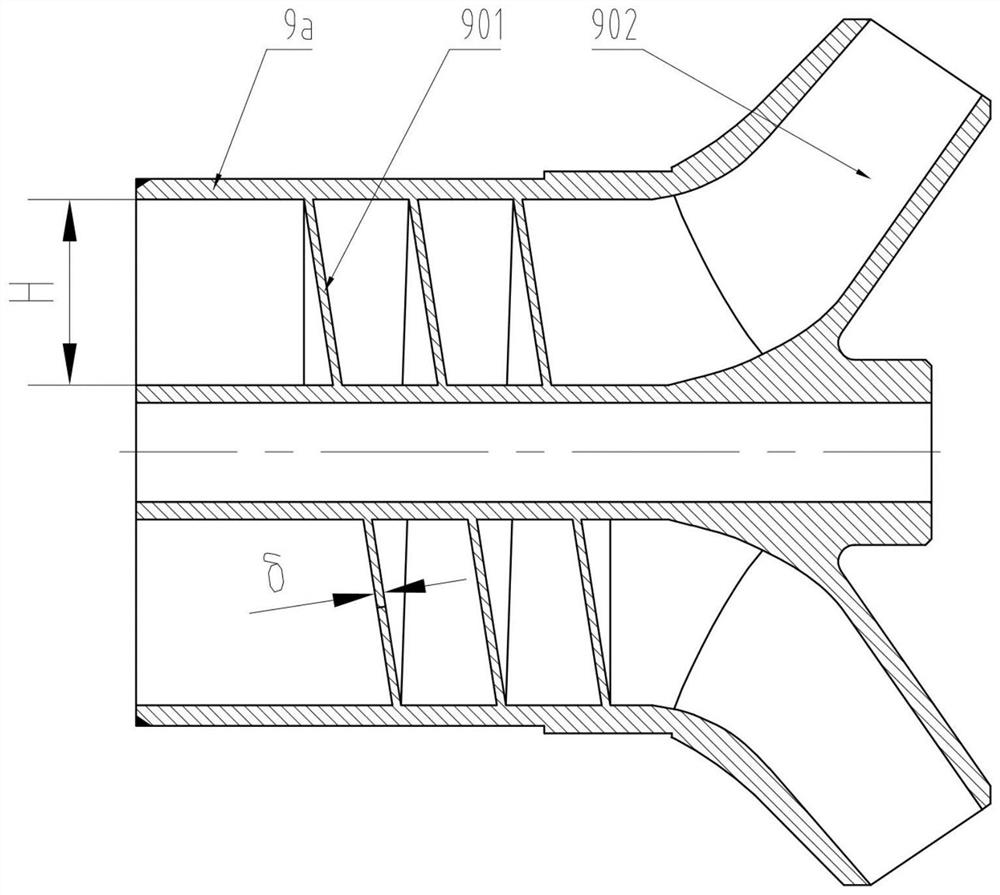

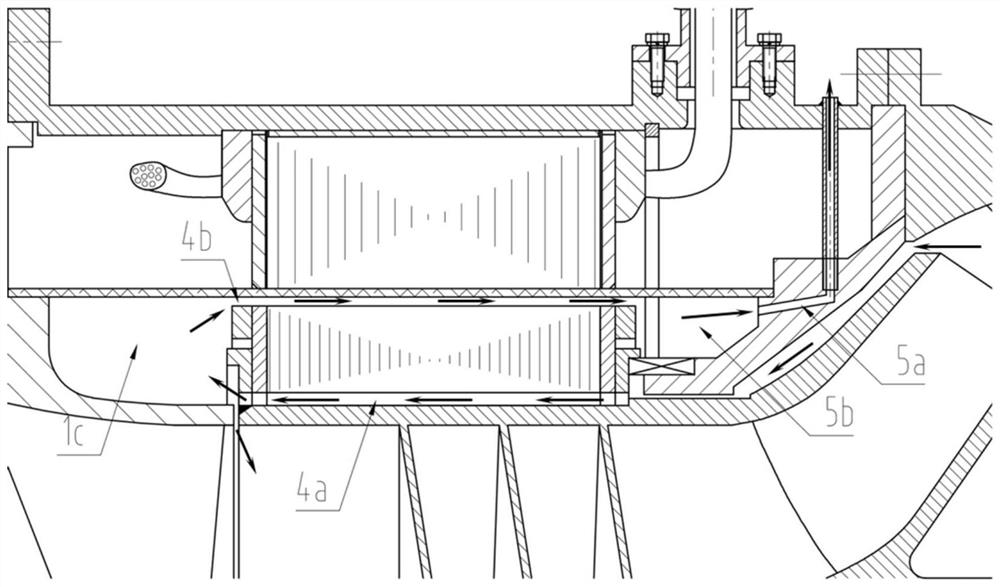

[0028] like figure 1 and figure 2 As shown in the figure, the impeller built-in high-speed centrifugal pump of the present invention includes a horn tube 1, a motor casing 2, a motor stator 3, a motor rotor 4, a motor baffle 5, a rear guide vane 6, a guide bearing 7, and a runner 9. , shaft 10 and bidirectional thrust bearing 13, the runner 9 is fixed on the shaft 10, and both ends of the shaft 10 are respectively installed with a guide bearing 7 and a bidirectional thrust bearing 13; The other end of the motor housing 2 is sequentially connected to the motor partition 5 and the rear guide vane 6 , and the motor stator 3 is fixed inside the motor housing 2 . The outer circle of the runner 9 is fixedly connected with the inner circle of the motor rotor 4. The runner 9 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com