An inner circulating cooling and cutting reducer of a horizontal axis roadheader

A technology for reducers and roadheaders, which is applied in gear lubrication/cooling, cutting machinery, mechanical equipment, etc. It can solve problems such as irreparable, small-diameter lubricating oil circuit blockage, high-speed stage temperature rise, etc., and achieve simple and convenient installation and operation , The effect of simple lubrication path and short lubrication path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the drawings

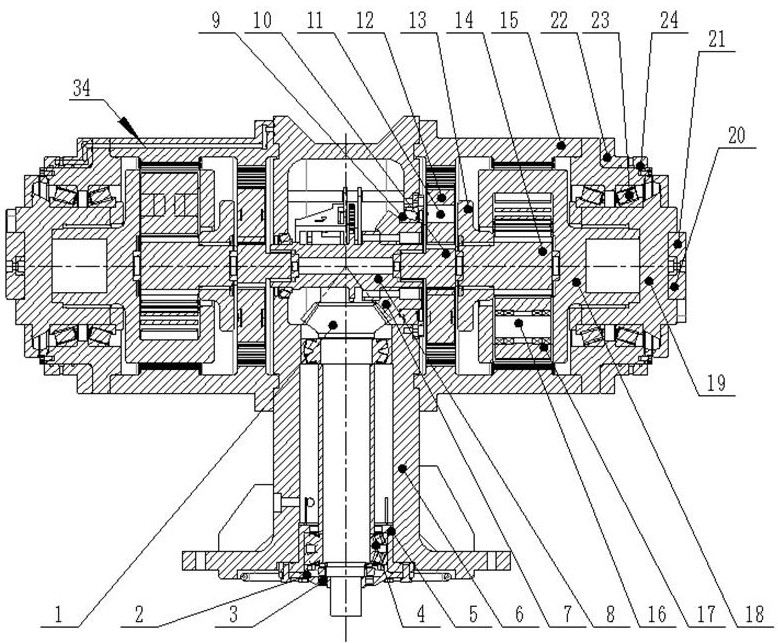

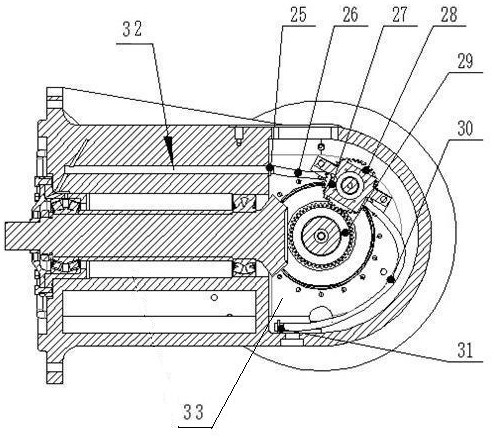

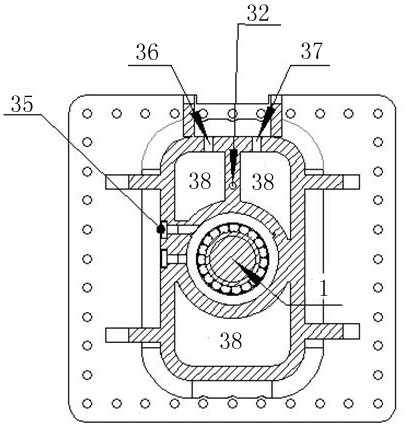

[0025] like figure 1 , figure 2 As shown, the first bevel gear 1 is connected with an external power source, the first bevel gear 1 is fixed on the bearing seat 5 through the bearing 4, the bearing seat 5 is installed in the housing 6, and the seal 3 is installed at the input end through the bearing cover 2 , to prevent the leakage of lubricating oil, the first bevel gear 1 meshes with the second bevel gear 7, the second bevel gear 7 is fixed to rotate with the horizontal shaft 8, the horizontal shaft 8 is fixed in the housing 6 through the bearing 9, the horizontal The shaft 8 is connected with the first-stage sun gear 10 to rotate together, the first-stage sun gear 10 is meshed with the first-stage planetary gear 12, and the first-stage planetary gear 12 is fixed on the first-stage planetary carrier 13 through the first-stage planetary shaft 11 , the first-stage planetary gear 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com