Method for quickly predicting critical failure stress of subgrade soil

A failure stress and prediction method technology, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, instruments, etc., can solve the problems of insufficient consideration of critical failure stress influencing factors, complex and time-consuming prediction process, etc., to achieve The effect of high marketing value, reducing test time consumption, and reducing test difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

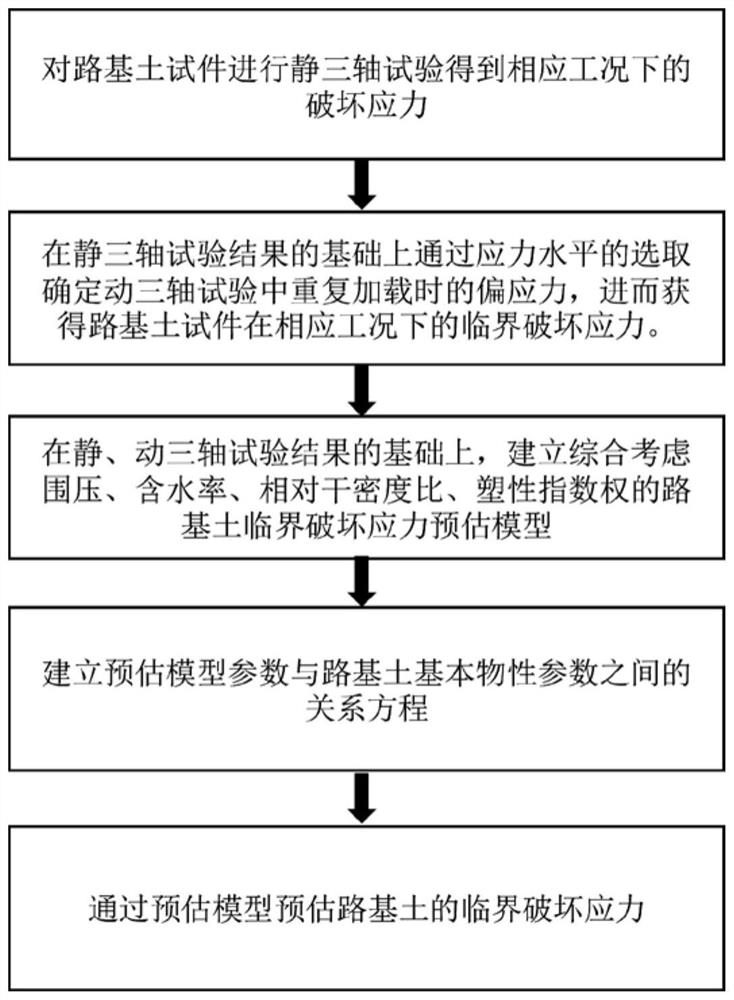

[0051] A rapid prediction method for the critical failure stress of subgrade soil, the process is as follows figure 1 As shown, the specific steps are as follows: the subgrade soil specimens were made with high liquid limit clay from Changsha, Hunan, and the basic physical parameters are shown in Table 1:

[0052] Table 1 Physical property index of high liquid limit clay

[0053]

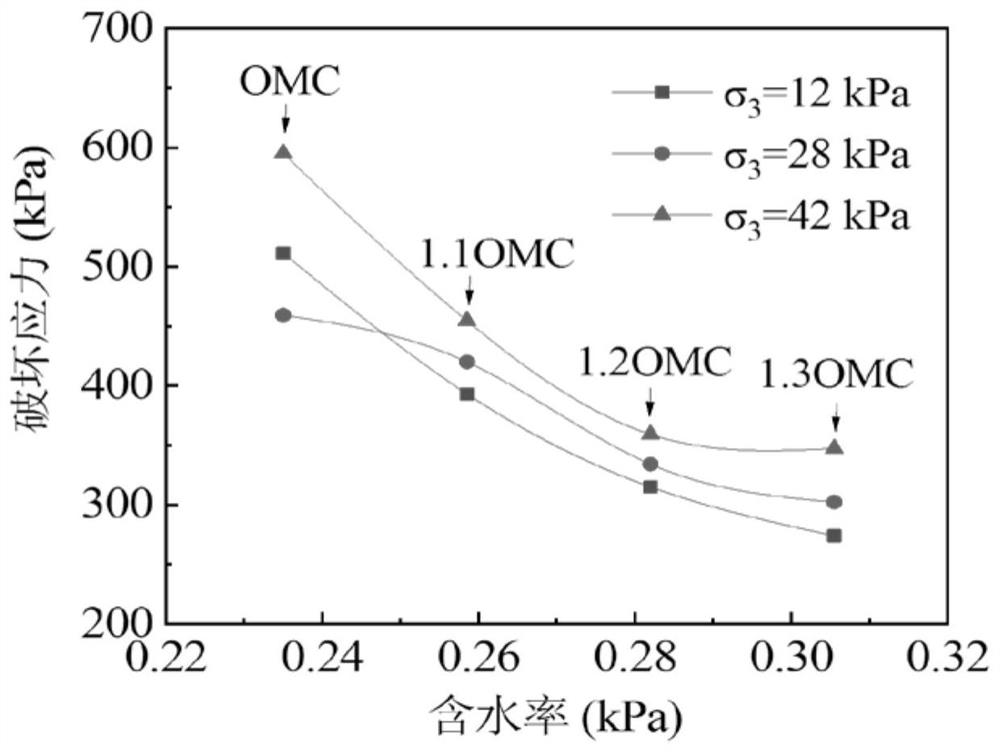

[0054] Step a: According to the maximum dry density and optimal moisture content determined by the compaction test results, prepare the selected subgrade soil according to the target compaction degree of 96% and the target moisture content of OMC, 1.1OMC, 1.2OMC, and 1.3OMC Subgrade soil test piece, the size of which is 10cm×20cm (diameter×height), is statically formed by a universal hydraulic testing machine. The static triaxial test is loaded with a strain rate of 0.02mm / s. If the specimen failure occurs before the axial strain reaches 15%, the peak point of the axial stress is taken as the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com