Manufacturing method of personalized lingual orthodontic appliance

A manufacturing method and a technology of aligners, which are applied in processing and manufacturing, manufacturing auxiliary devices, processing data acquisition/processing, etc., can solve the problems of insufficient length of anterior teeth, inability to fit in place, sliding left and right, etc., to improve the orthodontic effect , Easy to install, improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

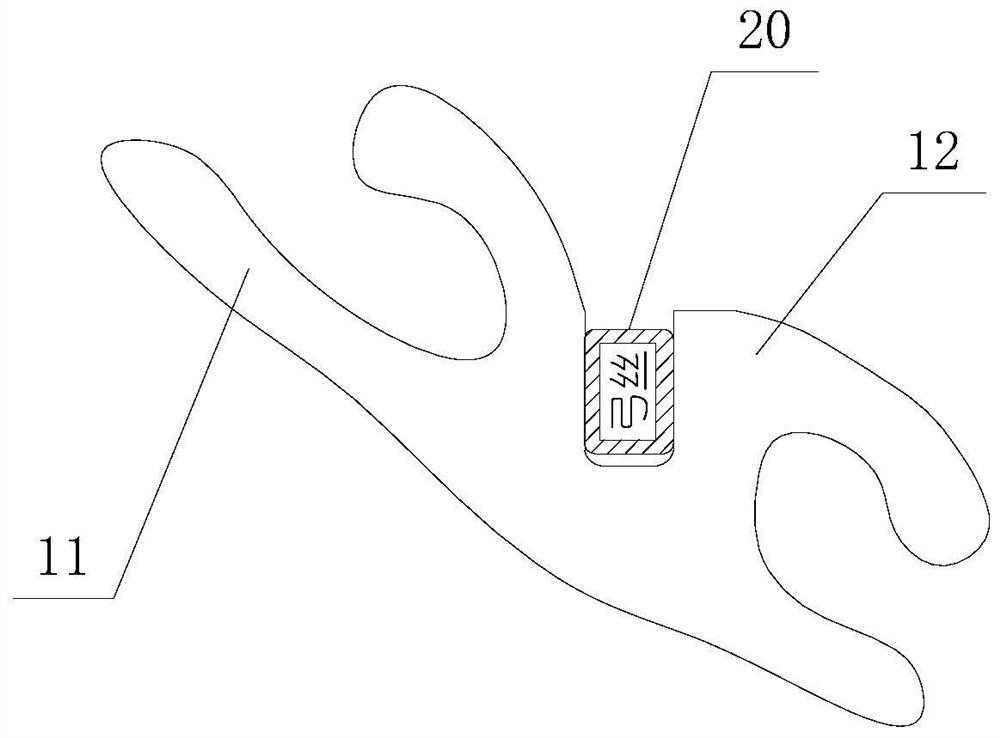

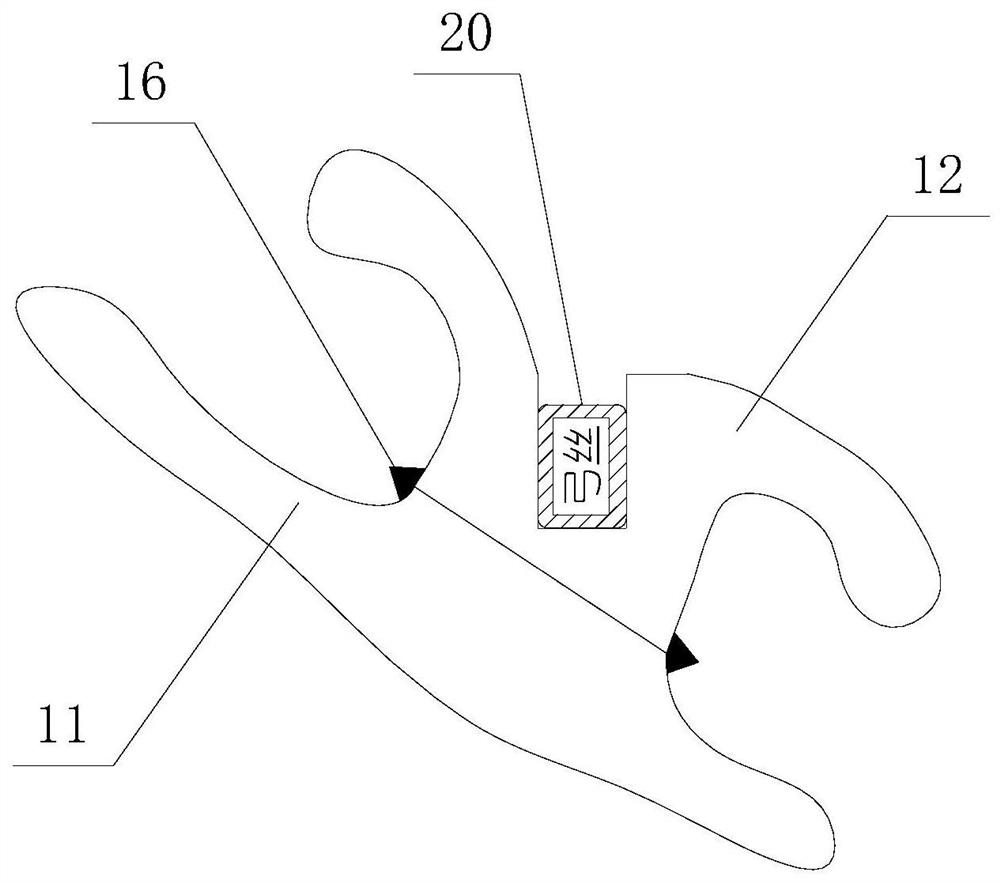

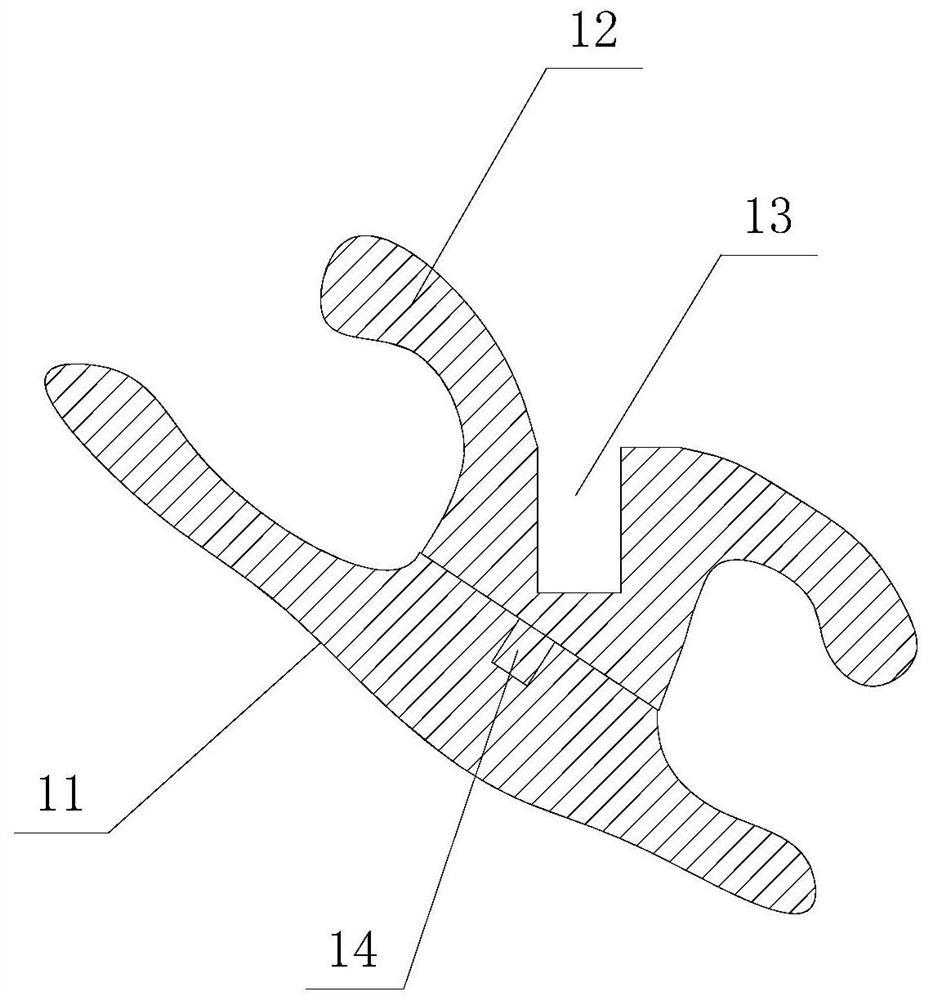

[0032] This embodiment provides a high-precision orthodontic bracket 10, including a bracket bottom plate 12 and a bracket body 11. The bracket body 11 adopts a high-precision bracket body 11 prepared by a mold process. The mold process refers to The mold is opened, and then the molten metal is introduced into the bracket body 11 made by the mold, such as figure 1 As shown, it is a bracket body 11 in the prior art, and the corner of the groove 13 of the bracket body 11 is a circular arc transition, Figure 2 to Figure 5 For the bracket body 11 provided in this embodiment, the corner of the groove 13 of the bracket body 11 is at a right angle, which is convenient for the archwire 20 to be completely in place, so that the force on the teeth 30 reaches an ideal state, which can shorten the orthodontic time and improve the orthodontic function. distorted effect.

[0033] In order to facilitate the industrialized high-precision production of the bracket body 11, the bracket body 1...

Embodiment 2

[0036] The manufacturing method of a personalized lingual orthodontic appliance provided by this embodiment is characterized in that it includes an orthodontic appliance manufactured according to the following sequential steps:

[0037] (1) Take the patient's original dental model and scan it or directly scan it in the mouth to obtain a digital dental model model, and combine the specific conditions of the patient's teeth 30 to arrange teeth on the digital dental model model, so as to obtain the ideal normal dentition shape suitable for the patient dentition model.

[0038] The original dental model uses professional silicone rubber material to copy the dentition in the mouth, and then pours the plaster model with superhard or zero-expansion gypsum. Multiple plaster models can be prepared according to the needs of doctors.

[0039] Then use a three-dimensional scanner to scan the plaster model (original dental model) to obtain a three-dimensional digital dental model, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com