Device for uniformly manufacturing PVC abrasive powder

A uniform and pulverizing technology, applied in the direction of solid separation, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inability to pulverize PVC bulk materials, not satisfying production and use, etc., and achieve the effect of improving quality and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

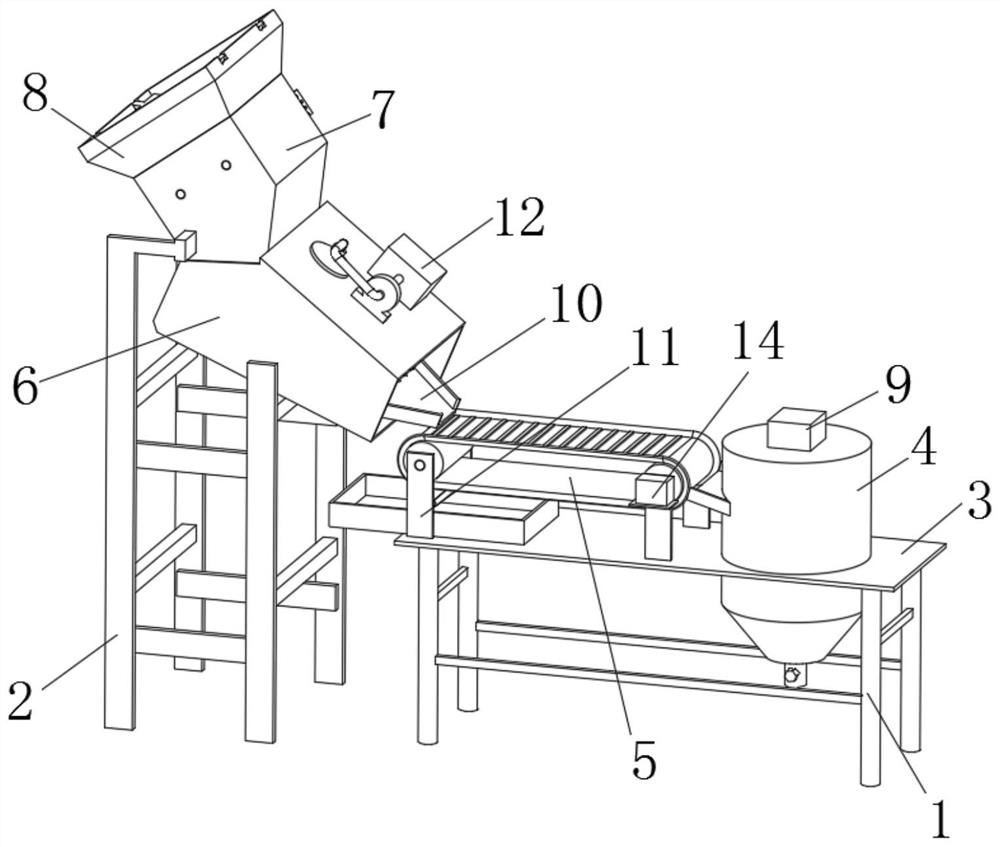

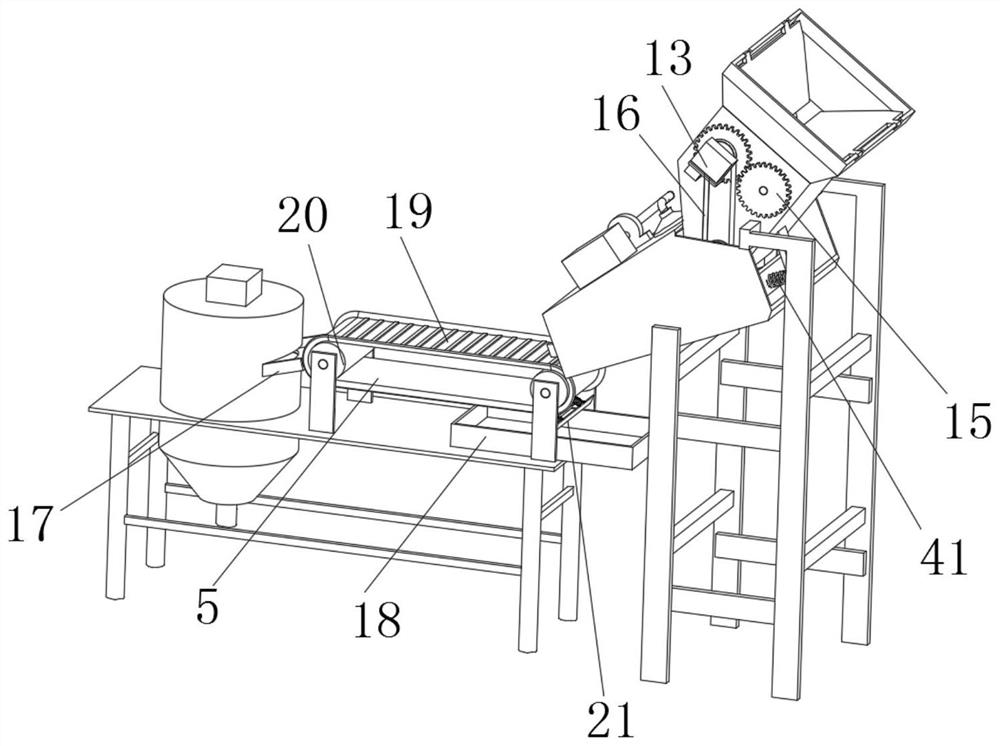

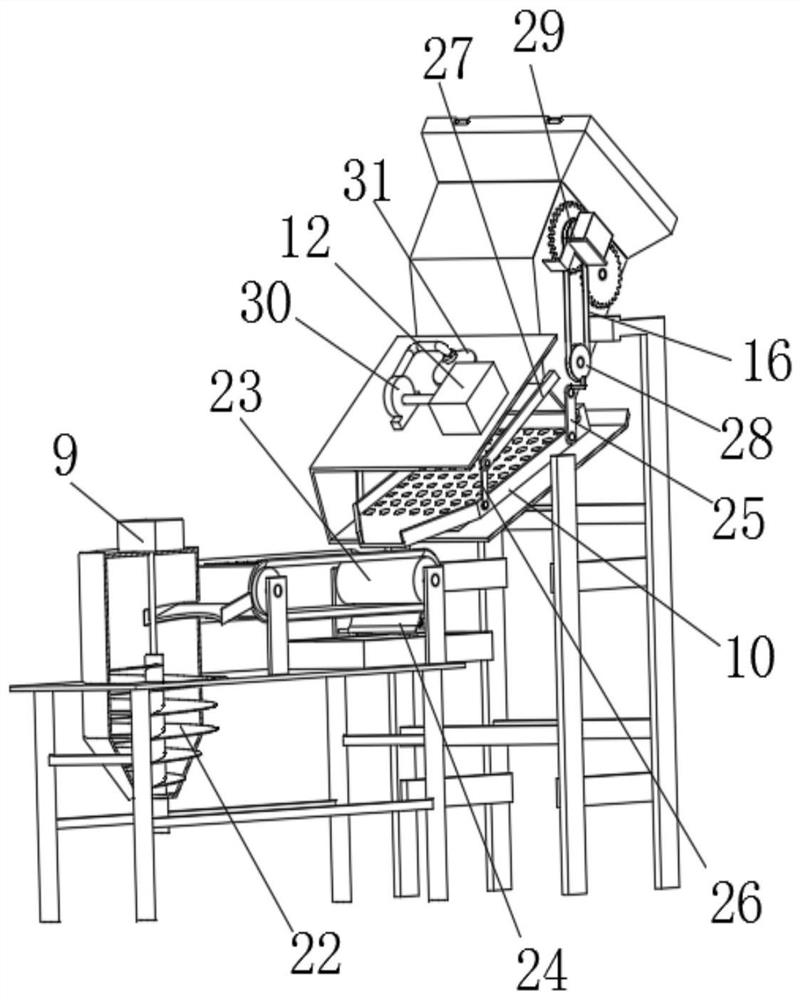

[0040] Example: Reference Figure 1-8 A device for producing uniform PVC grinding materials is shown, including a first support 1 and a second support 2 on one side of the first support 1. The first support 1 and the second support 2 can be welded by a plurality of profiles. The top of the first bracket 1 is fixedly connected with a fixed plate 3, and the fixed plate 3 is fixedly connected with the first bracket 1 by welding; the top of the fixed plate 3 is provided with a mounting hole, and the powder barrel 4 is fixedly sleeved in the mounting hole , the top of the powder barrel 4 is fixedly connected with a first motor 9.

[0041] The output end of the first motor 9 is fixedly connected with a rotating shaft 32, the rotating shaft 32 is fixedly sleeved with a fixed column 33, the fixed column 33 is fixedly sleeved with a helical blade 22, and the side wall of the fixed column 33 is fixedly connected with a plurality of different Long and short crushing blades 34 are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com