Painting device for cinerary casket processing

A technology for urns and placing boards, which is applied in the direction of spraying devices, devices for coating liquid on the surface, coatings, etc., and can solve problems such as strong smell, easy to get on the skin, and bad skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

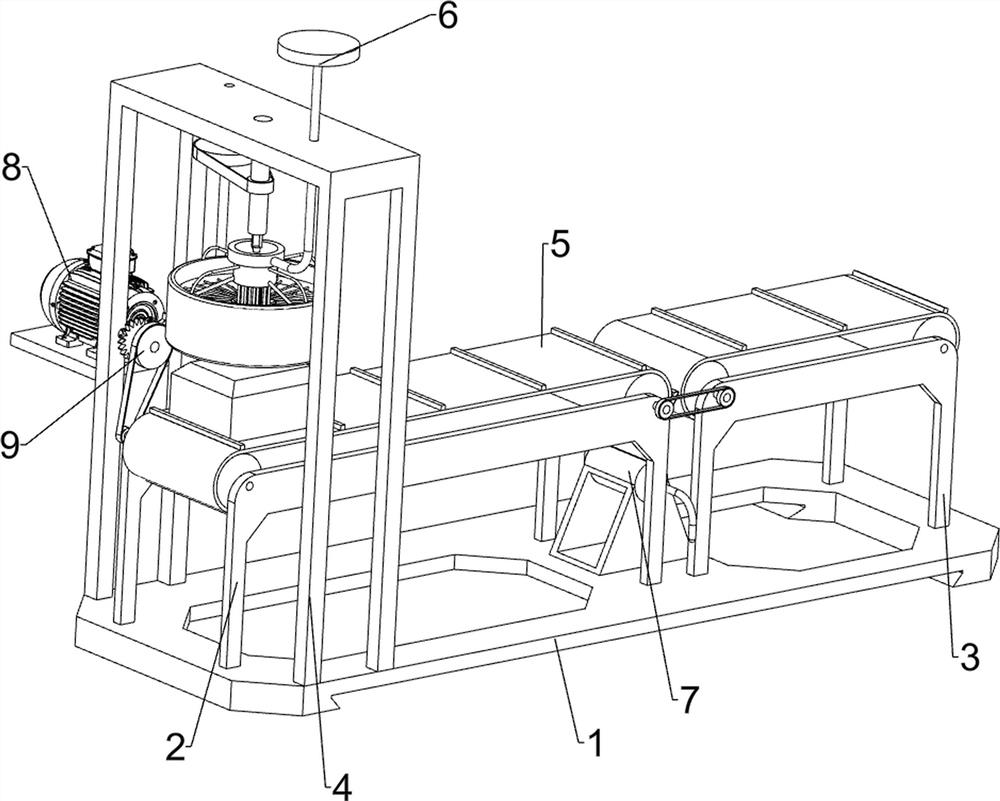

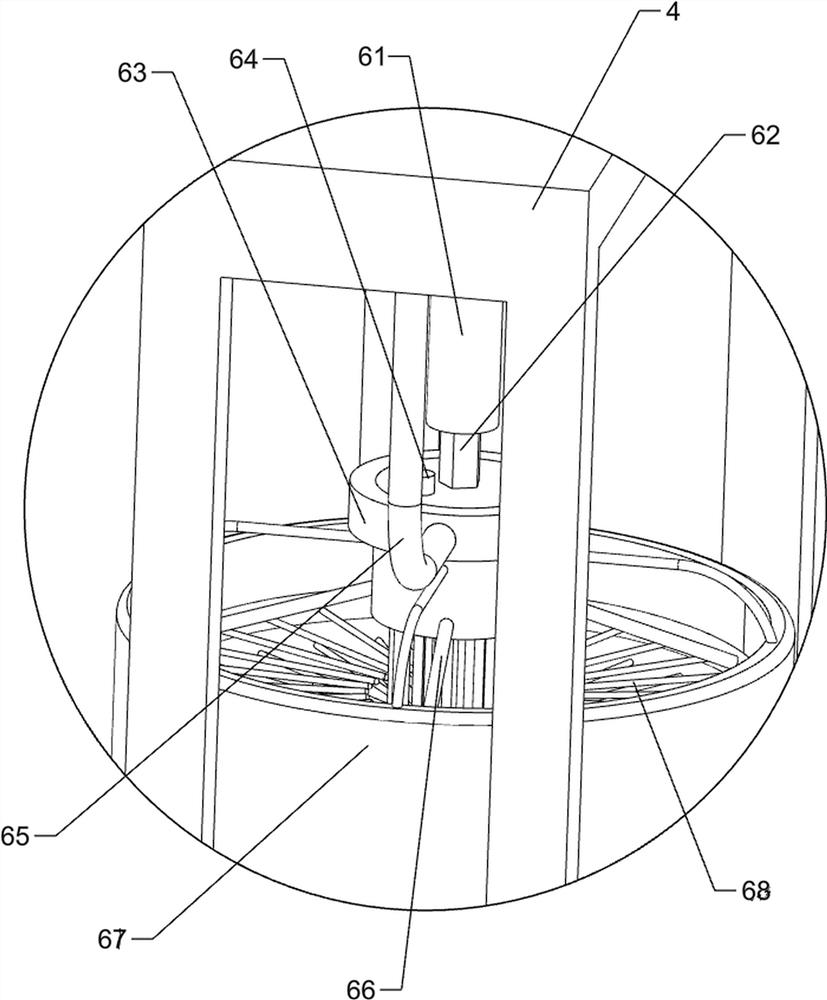

[0025] A kind of painting device for urn processing, such as figure 1 , figure 2 with image 3 As shown, it includes a placement board 1, a long bracket 2, a short bracket 3, a frame 4, a transport assembly 5, a lifting assembly 6 and a painting assembly 7, and the left side of the placement board 1 is connected with a long bracket 2 on the front and rear sides, and the placement board 1. Short brackets 3 are connected to the front and rear sides of the right part. The short bracket 3 is directly to the right of the long bracket 2. The frame 4 is connected to the left side of the top of the placement plate 1. The upper part of the long bracket 2 and the short bracket 3 is rotatably connected to the transportation component 5. The upper part of the frame 4 is slidably connected with a lifting assembly 6, and the middle of the top of the placing plate 1 is connected with a painting assembly 7.

[0026] The transportation assembly 5 includes a first roller 51, a first belt 52,...

Embodiment 2

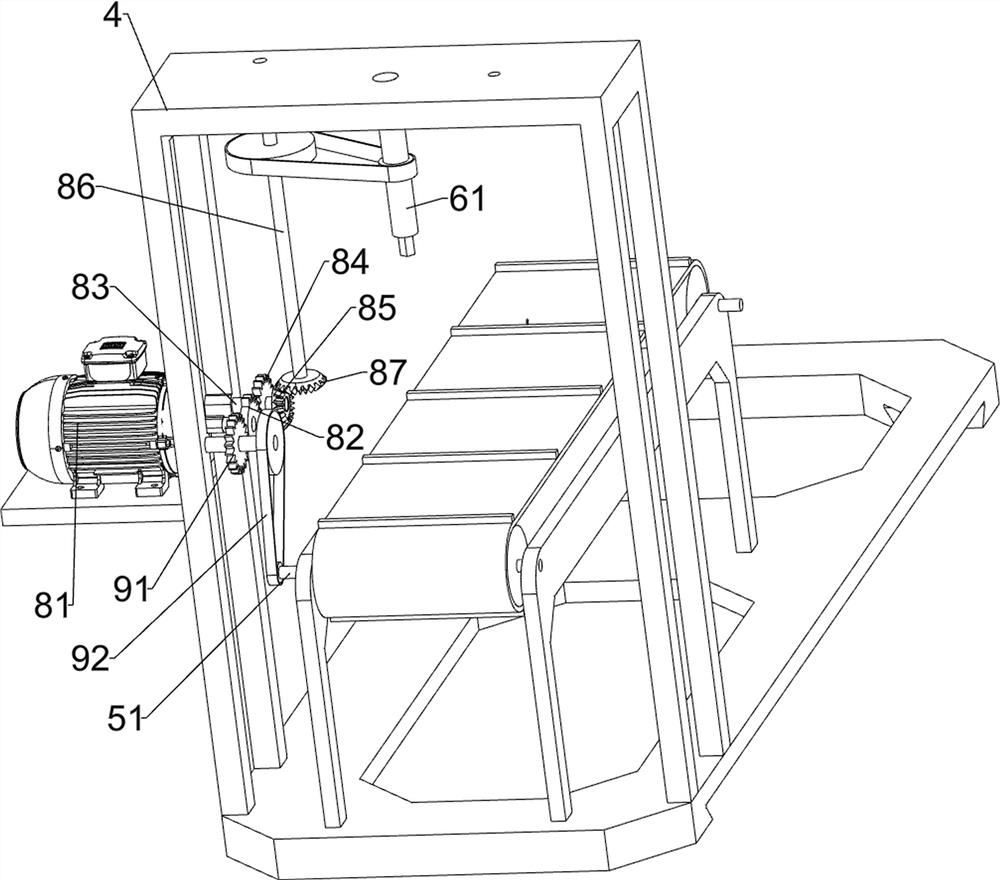

[0031] On the basis of Example 1, such as Figure 4 As shown, a drive assembly 8 is also included, and the drive assembly 8 includes a motor 81, a missing gear 82, a first rotating shaft 83, a first gear 84, a first bevel gear 85, a second rotating shaft 86 and a second bevel gear 87, and the frame 4. A motor 81 is installed on the rear side of the upper part. A missing gear 82 is connected to the output shaft of the motor 81. The rear side of the upper part of the frame 4 is rotatably connected with a first rotating shaft 83. The first rotating shaft 83 is connected with a first gear 84 in the middle. The first gear 84 Mesh with the missing gear 82, the front side of the first rotating shaft 83 is connected with the first bevel gear 85, the upper part of the frame 4 is rotatably connected with the second rotating shaft 86, and the lower part of the second rotating shaft 86 is connected with the second bevel gear 87, the second bevel gear 87 is meshed with the first bevel gear...

Embodiment 3

[0034] On the basis of Example 2, such as Figure 4 As shown, a transmission assembly 9 is also included, the transmission assembly 9 includes a second gear 91 and a transmission belt set 92, the upper rear side of the frame 4 is rotatably connected with a second gear 91, and the second gear 91 meshes with the missing gear 82, A drive belt set 92 is connected between the second gear 91 and the first roller 51 on the left.

[0035] When the missing gear 82 is not meshed with the first gear 84, the missing gear 82 rotates to drive the second gear 91 to rotate, and the second gear 91 rotates to drive the first roller 51 on the left side to rotate, so that there is no need to manually rotate the first roller on the left side 51 transport the urns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com