Welding device with high safety performance for manufacturing mining mechanical equipment

A technology of safety performance and mechanical equipment, applied in the field of welding devices for mining machinery and equipment manufacturing, can solve the problems of user workload, multi-working hours, occupation, etc., reduce the amount of action, meet the complex use environment, and avoid the problem of easy damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

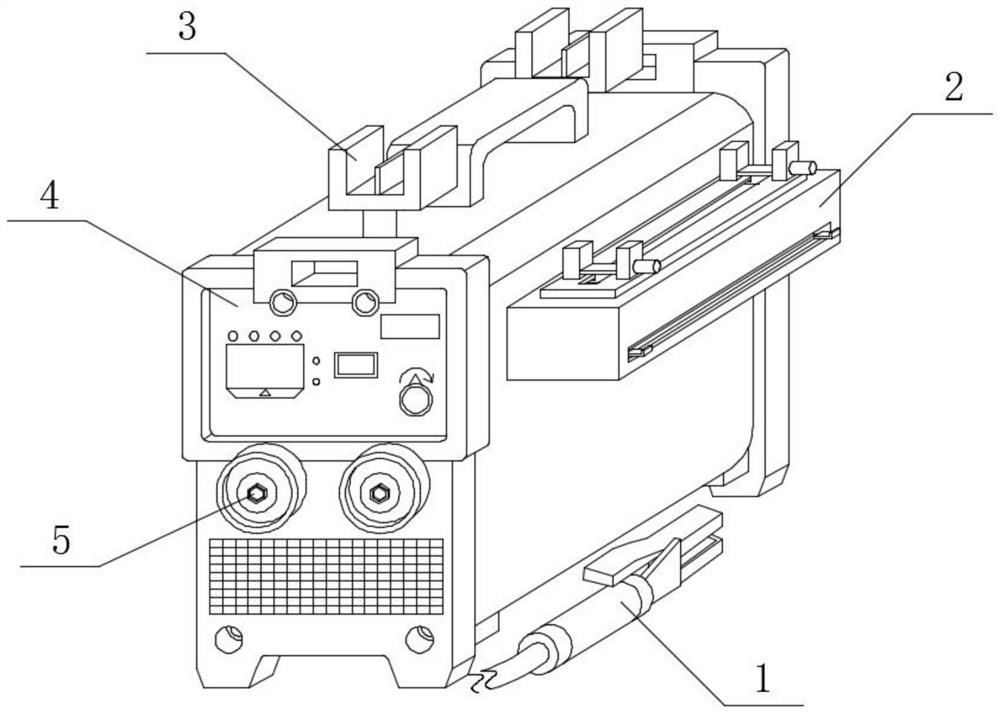

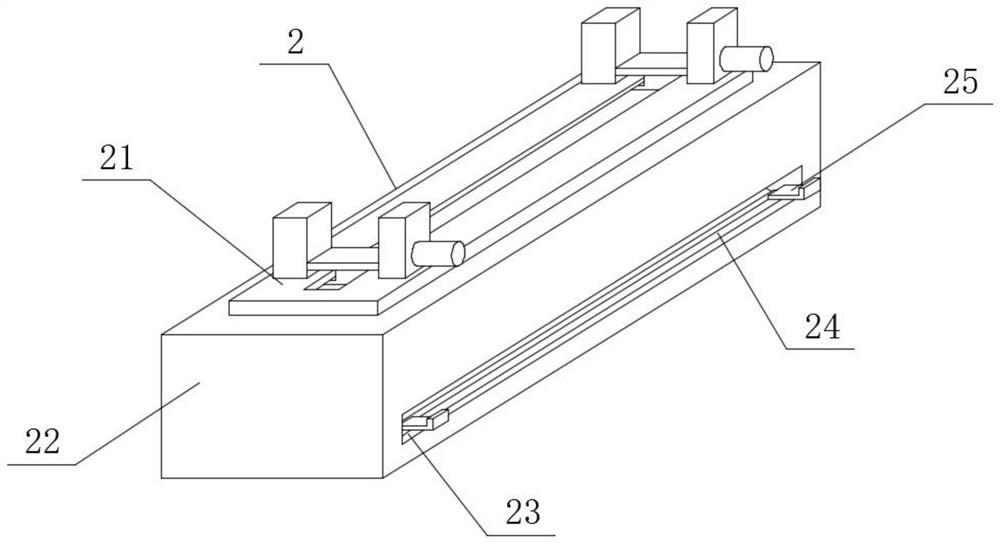

[0027] Such as Figure 1-2 As shown, a welding device with high safety performance for the manufacture of mining machinery and equipment includes a chassis 4, the top of the chassis 4 is movably connected with a fixing fixture 3 through threads, and the front end face of the chassis 4 is provided with a connecting hole 5, and the connecting hole 5 A welding tongs 1 is movably connected to the inner surface, and a welding rod cabinet 2 is fixedly connected to the side end of the cabinet 4. The welding rod cabinet 2 includes a long cabinet 22, and the top of the cover plate 21 is connected to the cover plate 21 by hinge rotation, and the long cabinet 22 The right end of the outlet is provided with a discharge chute 23, the inner surface of the discharge chute 23 is plugged and movably connected with a connecting plate 24, and the top of the connecting plate 24 is fixedly connected with a protruding plate 25.

[0028] During use, spare welding rods can be placed on the inner side...

Embodiment 2

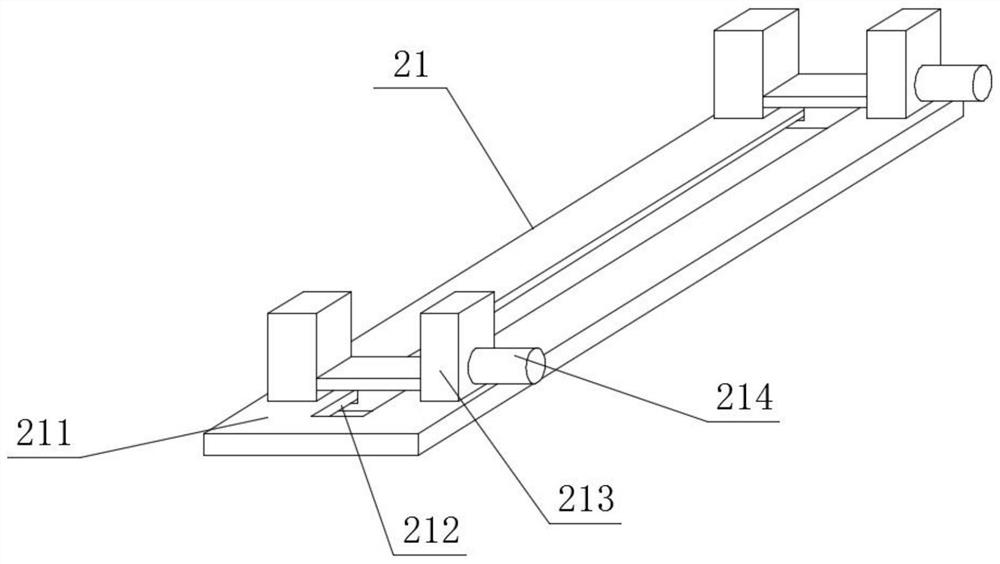

[0030] Such as Figure 1-3 As shown, a welding device with high safety performance for the manufacture of mining machinery and equipment includes a chassis 4, the top of the chassis 4 is movably connected with a fixing fixture 3 through threads, and the front end face of the chassis 4 is provided with a connecting hole 5, and the connecting hole 5 A welding tongs 1 is movably connected to the inner surface, and a welding rod cabinet 2 is fixedly connected to the side end of the cabinet 4. The welding rod cabinet 2 includes a long cabinet 22, and the top of the cover plate 21 is connected to the cover plate 21 by hinge rotation, and the long cabinet 22 The right end of the chute is provided with a discharge chute 23, the inner surface of the discharge chute 23 is movably connected with a connecting plate 24, and the top of the connecting plate 24 is fixedly connected with a protruding plate 25, and the cover plate 21 includes a flat plate 211, the flat plate 211 The top is prov...

Embodiment 3

[0033] Such as Figure 1-4 As shown, a welding device with high safety performance for the manufacture of mining machinery and equipment includes a chassis 4, the top of the chassis 4 is movably connected with a fixing fixture 3 through threads, and the front end face of the chassis 4 is provided with a connecting hole 5, and the connecting hole 5 A welding tongs 1 is movably connected to the inner surface, and a welding rod cabinet 2 is fixedly connected to the side end of the cabinet 4. The welding rod cabinet 2 includes a long cabinet 22, and the top of the cover plate 21 is connected to the cover plate 21 by hinge rotation, and the long cabinet 22 The right end of the chute is provided with a discharge chute 23, the inner surface of the discharge chute 23 is movably connected with a connecting plate 24, and the top of the connecting plate 24 is fixedly connected with a protruding plate 25, and the fixing fixture 3 includes a limit clamp 31, a limit clamp 31 A boundary plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com