Automatic production line for sweet potato nutritional meal powder

An automatic production line, sweet potato technology, applied in food drying, food science, food heat treatment and other directions, can solve the problems of sweet potato food inconvenient to eat, pantothenic acid, inconvenient to eat, etc., to avoid moisture or pollution, nutritional balance, convenient to eat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings of the description.

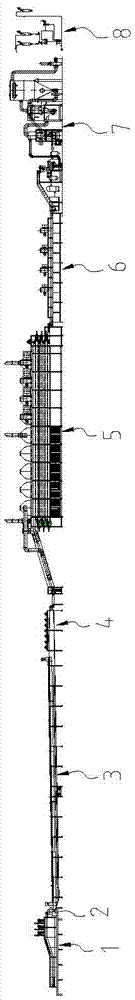

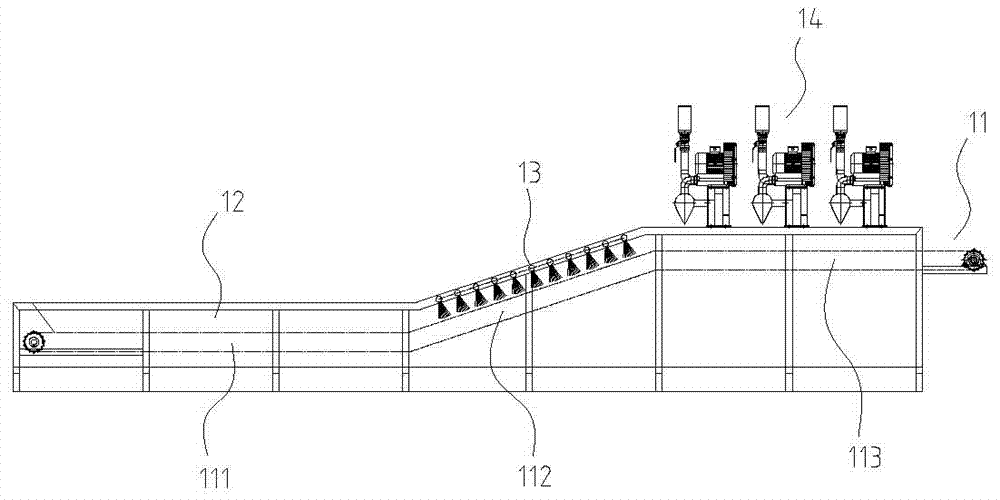

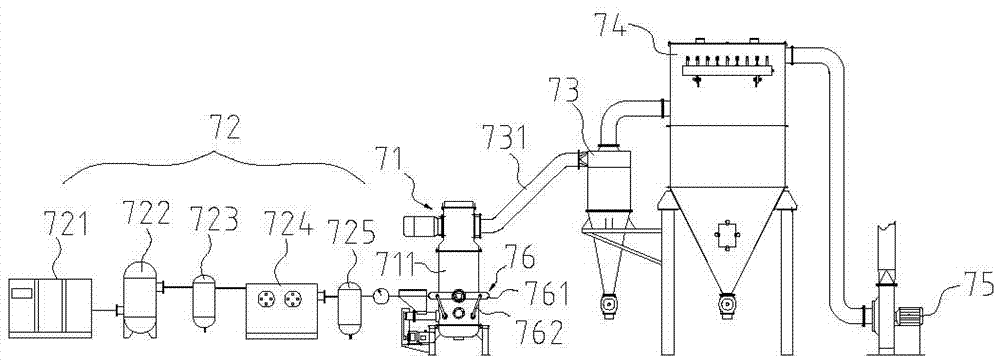

[0035] Such as figure 1 As shown, an automatic production line for sweet potato nutritional meal powder includes a cleaning device 1 for cleaning fresh sweet potatoes without destroying the skin of sweet potatoes, a slicing device 2 for slicing sweet potatoes, and a cleaning device for steaming sweet potatoes according to the material conveying direction. Cooking device 3, first cooling device 4 for cooling sweet potatoes, drying device 5 for drying fresh sweet potato chips, second cooling device 6 for cooling dry potato chips, crushing device for crushing sweet potatoes 7. A dry powder powder mixing device 8 and a packaging device for mixing sweet potato powder and nutritional powder. The output end of the cleaning device 1 is docked with the input end of the slicing device 2, the output end of the slicing device 2 is connected with the cooking dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com