Punching device for long-life precision mold manufacturing

A technology of precision molds and punching equipment, which is applied in metal processing, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inconvenient adjustment of the depth of punching, poor applicability, etc. The effect of strong practicality and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

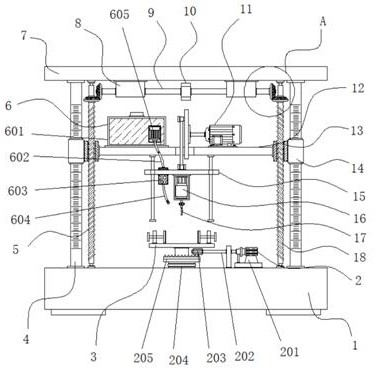

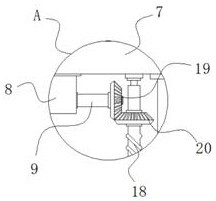

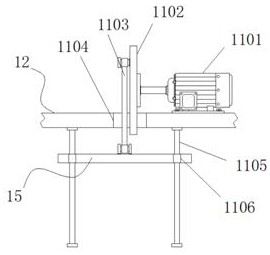

[0035]Example 1: SeeFigure 1-6, A hole in a long life precision mold, including a base 1 and a table 3, and a table 3 is disposed at the intermediate position at the top of the base 1, and the top end of the table 3 is provided with facilitating structural 21, the workbench 3 A automatic rotating mechanism 2 is provided between the bottom end and the top end of the base 1, and both sides of the top end of the base 1 are respectively fixed, and the support column 4 is fixed, respectively, and the front end of the support column 4 is provided with a scale label, and the top end of the support column 4 is fixedly connected to the top plate. 7. A cross plate 12 is provided between the support columns 4, and the bottom end of the cross plate 12 is provided with a fixing plate 15. The bottom end of the fixing plate 15 is fixedly connected to the drive motor 16, and the model number of the drive motor 16 can be Y80M2-2, drive The output of the motor 16 is fixedly connected to the drill bit...

Embodiment 2

[0040]Example 2: The automatic rotating mechanism 2 consists of a stepper motor 201, a rotating shaft 202, a pinion 203, a movable shaft 204, and a large gear 205, and the bottom end of the movable shaft 204 is fixed to the top end of the base 1, and the top end of the movable shaft 204 is fixed Connected to a large gear 205, the step motor 201 is fixed to one side of the top end of the base 1, and the model number of the step motor 201 can be XC866, and the output end of the step motor 201 is fixedly connected to the shaft 202, and the rotating shaft 202 is fixedly connected. There is a pinion gear 203, and the top end of the large gear 205 is fixed to the bottom end of the table 3;

[0041]The pinion gear 203 is engaged between the large gear 205, and the pinion 203 is in the same vertical surface on one side of the large gear 205;

[0042]Specifically, such asfigure 1 withFigure 6 As shown, in use, the step motor 201, the step motor 201 drives the shaft 202, and the rotating shaft 202 ...

Embodiment 3

[0043]Example 3: The dust collecting mechanism 6 is composed of a water tank 601, a hose 602, a nebulator 603, a spray head 604, and a water pump 605, and the water tank 601 is fixedly attached to one side of the top end of the cross plate 12, and a water pump is fixed to one side of the front end of the water tank 601. 605. The model number of the water pump 605 can be 350qz-50, and the output of the water pump 605 is fixedly connected to the hose 602, and the atomizer 603 is fixedly attached to the inside of the fixed plate 15 side, and the bottom end of the atomizer 60 is fixedly connected to nozzle. 604;

[0044]Specifically, such asfigure 1 As shown, in use, the water pump 605 is activated, and the water pump 605 can extract the water inside the water tank 601 and supplied to the nebulizer 603 by the hose 602, and the atomizer 603 is ejected by the spray head 604, so that The driver motor 16 boosted the dust generated in the process of high-speed rotation of the drill bit 17 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com