A scissor foot inner and outer frame automatic folding machine

A technology of inner and outer frames and scissor feet, which is applied in household appliances, household components, and other household appliances, can solve the problems of low processing efficiency, high labor cost, and easily damaged products, and achieve improved product yield, convenient operation, and convenience The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

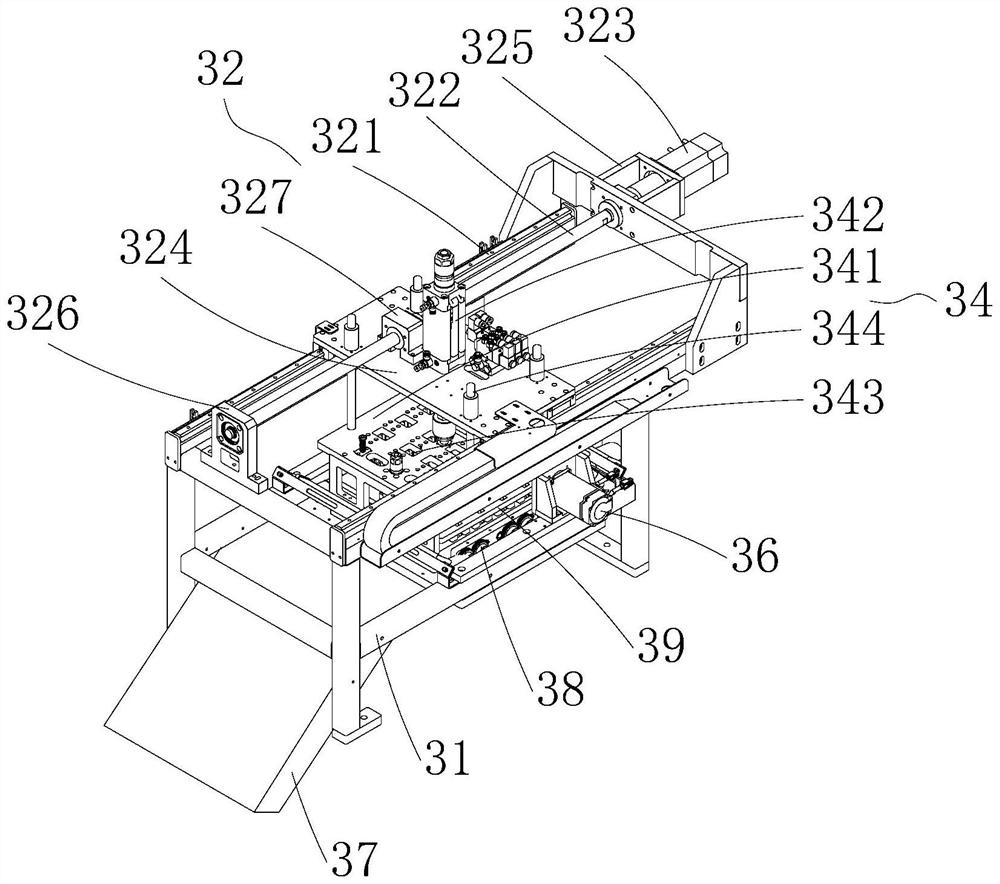

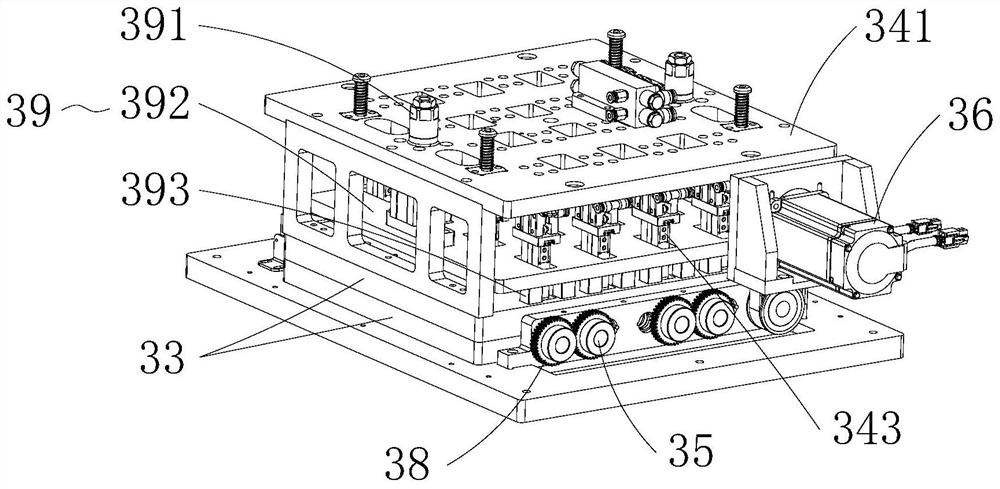

[0029] The present invention is now described in further detail in conjunction with the accompanying drawings. These drawings are simplified schematic diagrams, illustrating only the basic structure of the present invention in a schematic manner, so that it only shows the composition associated with the present invention.

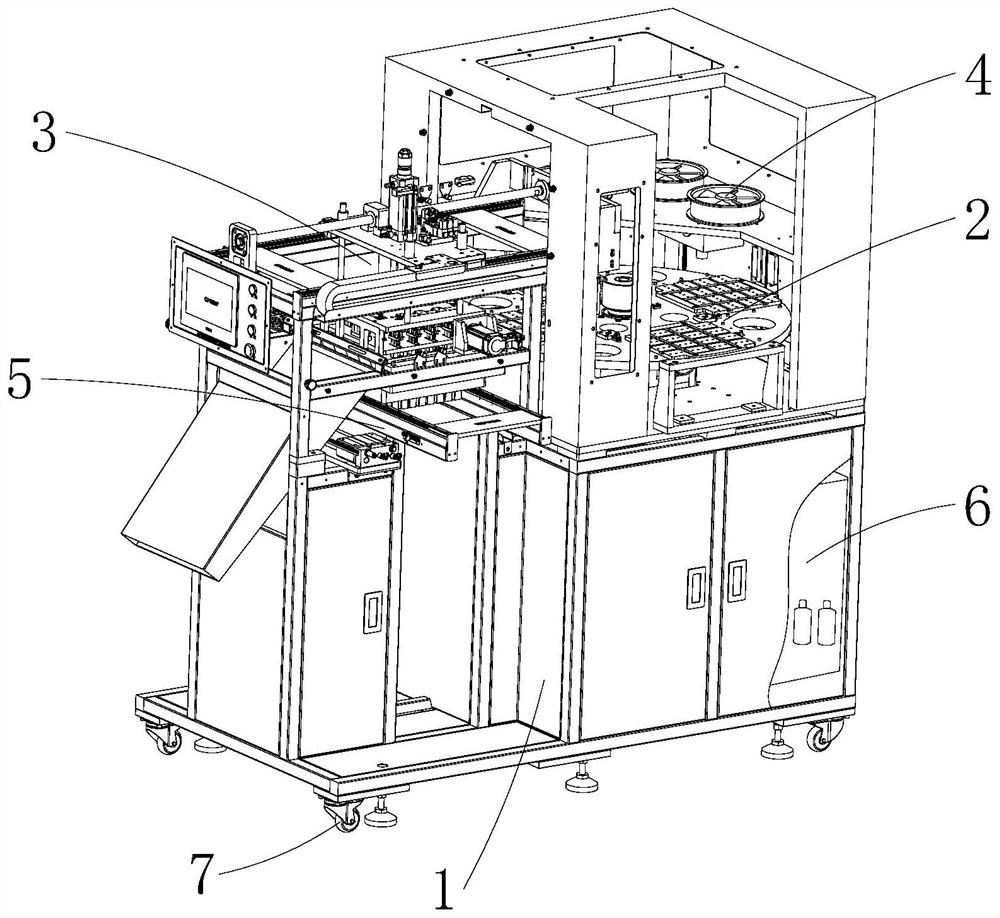

[0030] See Figure 1 , the present invention provides a scissor foot inner and outer frame automatic folding strip machine, comprising a rack 1, the rack 1 is provided with a multi-station turntable mechanism 2 and a transplanting breaking mechanism 3, the multi-station turntable mechanism 2 is provided above the air-cooled electrostatic mechanism 4, the transplanting breaking mechanism 3 is provided below the duplex collection mechanism 5;

[0031] The machine can be used with injection molding machine online production, injection molding products are delivered by the injection molding machine manipulator (pictured in the picture) to the multi-station turntable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com