A four-wheel drive system for an all-terrain vehicle

A transmission system and technology for all-terrain vehicles, applied in the field of all-terrain vehicles, can solve problems such as affecting vehicle stability, unsuitable layout, and harsh driving conditions, so as to improve transmission efficiency and dynamic response speed, improve vehicle stability, Compact and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical solutions of the present invention, the present invention will be described in detail below through specific embodiments.

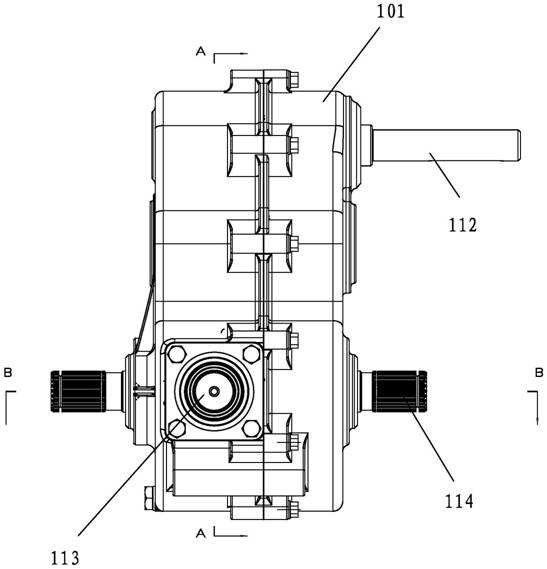

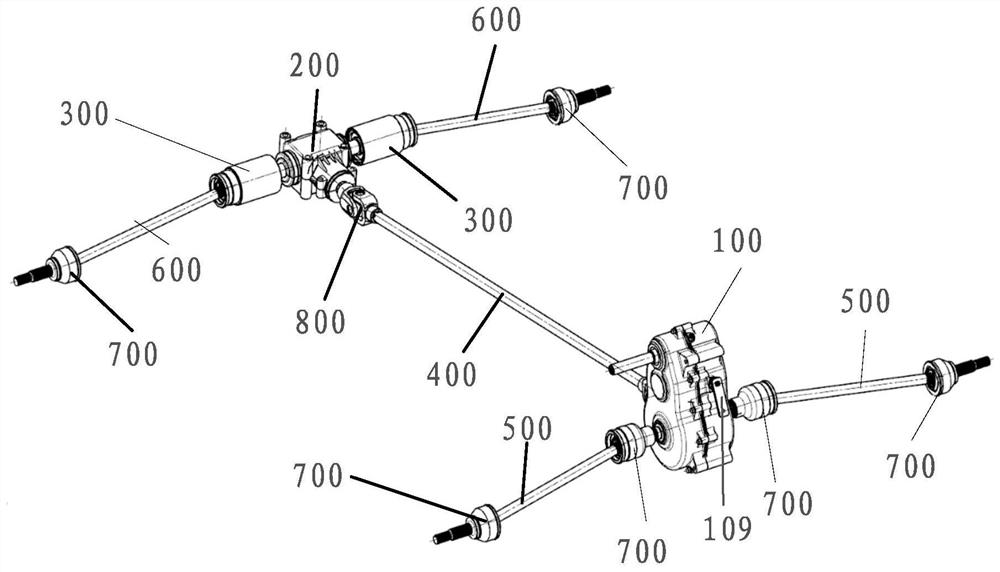

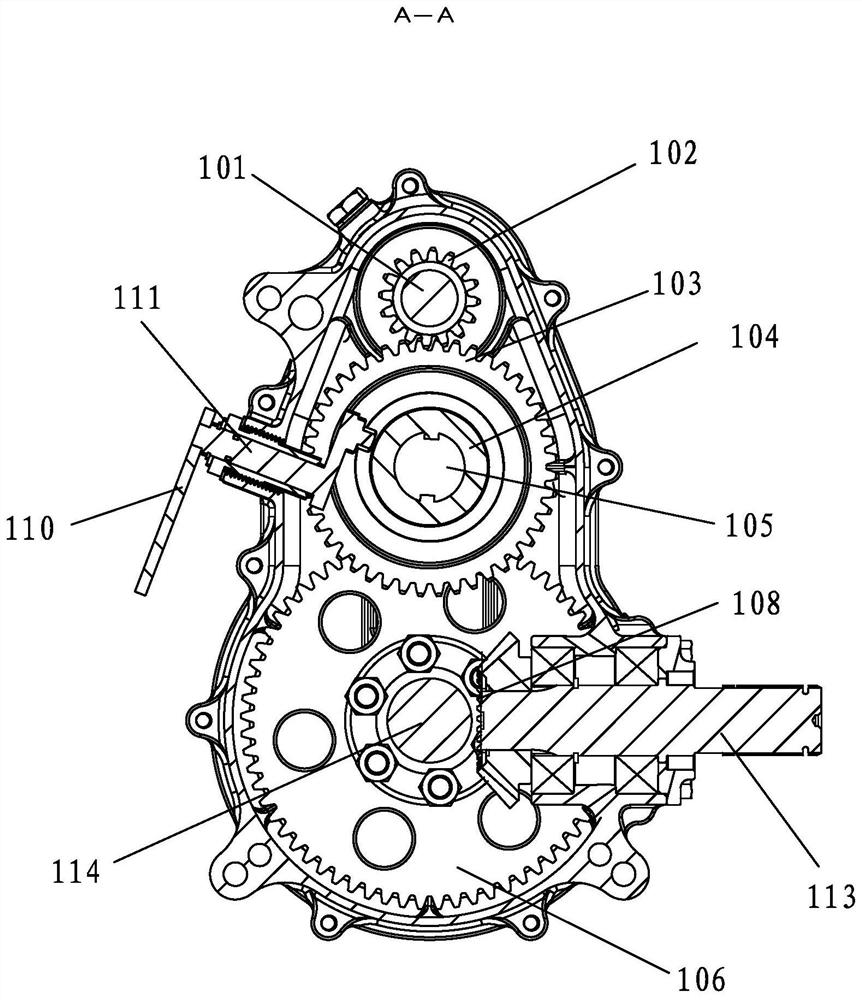

[0035] like Figure 1-8 As shown, this case provides a four-wheel drive transmission system for an all-terrain vehicle, which includes a rear axle transfer reducer 100, a front axle reducer 200, a coupling 300, an intermediate transmission shaft 400, two rear axle shafts 500 and two front half shafts 600, the front half shaft 600 is connected to the front wheel of the car through the constant velocity joint 700, and the rear half shaft 500 is connected to the rear wheel of the car through the constant velocity joint 700. The rear axle transfer reducer 100 includes a first input shaft 112 connected with the engine, a middle output shaft 113 connected with the first input shaft 112 in a driving manner, and a cross universal joint is passed between the first input shaft 112 and the middle output shaft 113 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com