Rod packaging machine and packaging method

A technology for sticks and packaging machines, applied in the directions of packaging, wrapping paper, wrapping paper shrinkage, etc., can solve the problems of difficult discharge and packaging, high requirements for operators, affecting work efficiency, etc., so as to improve work efficiency and improve grasping. effect, the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following detailed description will explain the general principles of the invention, examples of which are further illustrated in the accompanying drawings. In the drawings, like reference numbers indicate identical or functionally similar elements. As used herein, the term cloth tape may include any required soft tape, such as anti-corrosion cloth, protective film, protective foam tape, etc.; the term sleeve may include any required tubular object, such as metal pipe, PVC Tubes, etc.; the term hose can include any required hoses, such as heat-shrinkable tubes, plastic hoses, etc.; surface treatment mechanisms can be used to clean the surface of rods, such as phosphorus removal, rust removal, dust removal, foreign matter removal, etc., or for Surface coating of rods, such as cleaning fluid, lubricating oil, paint, protective coating, anti-rust oil, etc.

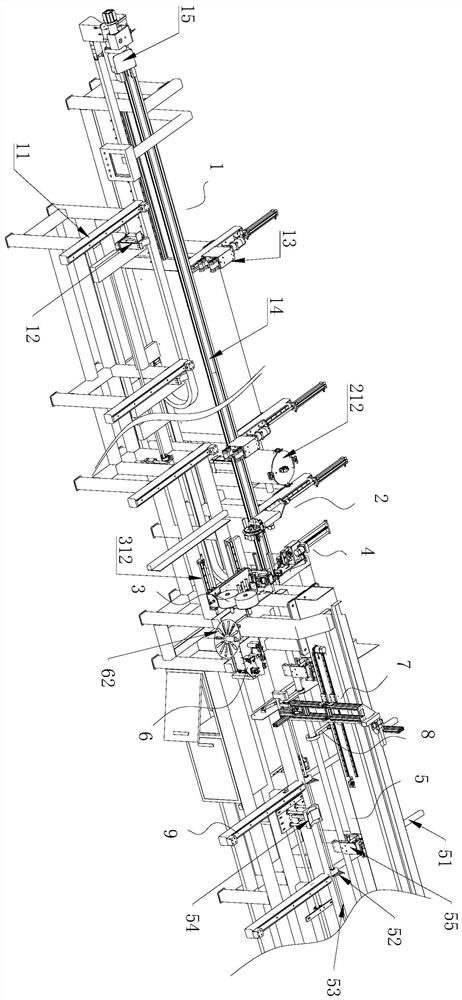

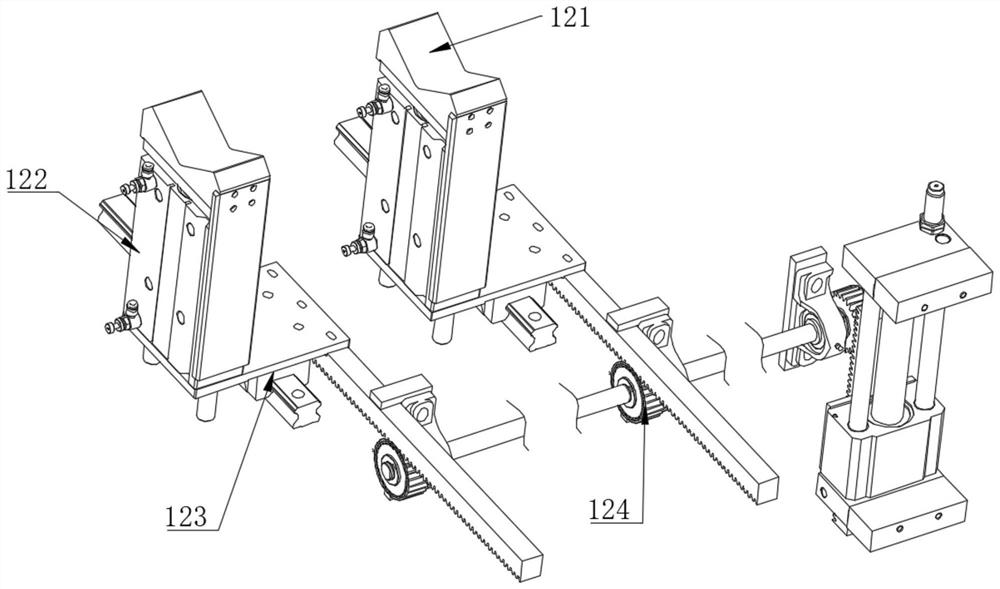

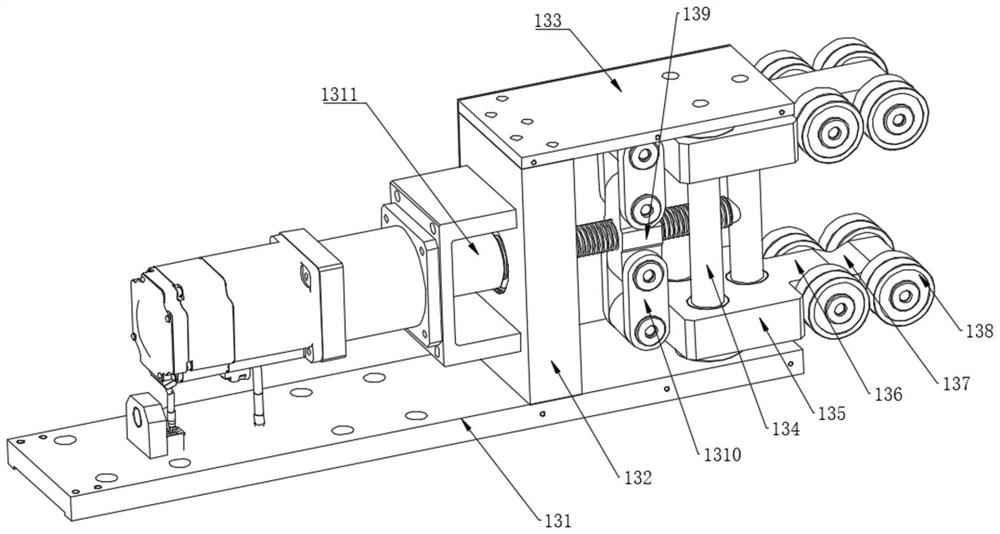

[0049] as attached Figure 1-9 As shown, the present invention provides a stick packaging machine, including a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com