Wood varnish and preparation method thereof

A technology of wood varnish and main paint, applied in the field of coatings, can solve the problems of easy damage of leather, difficult to use for a long time, etc., achieve good hand feeling, good wear resistance and scratch resistance, and increase market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

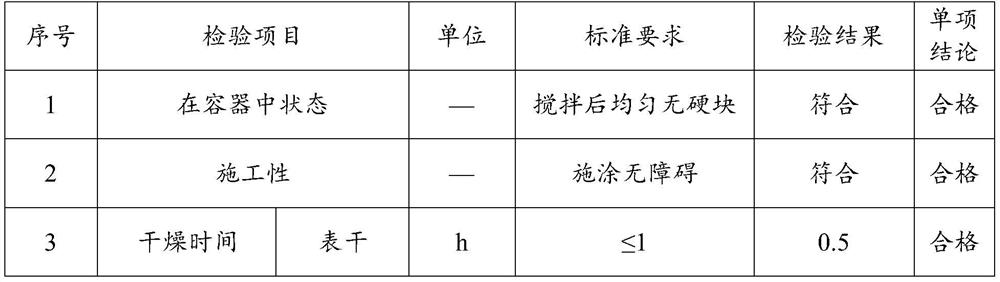

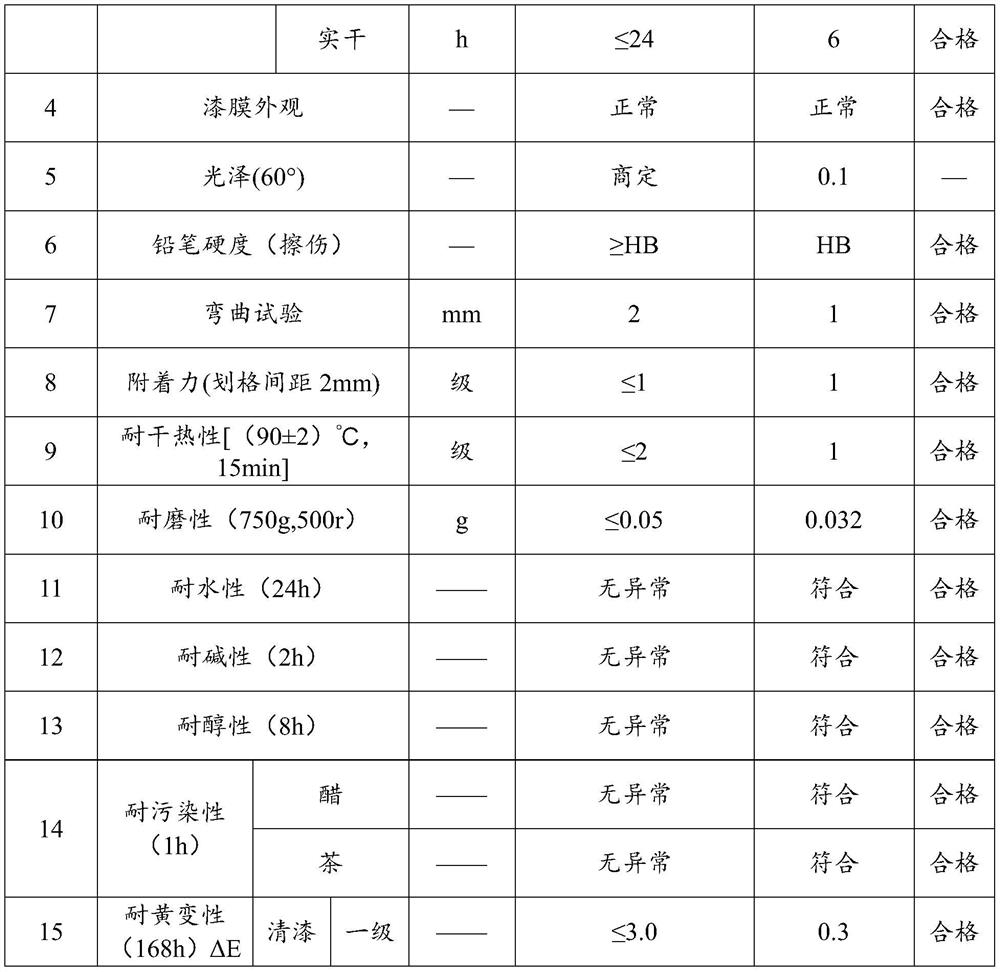

Examples

Embodiment 1

[0082] This embodiment prepares a kind of wood varnish, comprises main paint, curing agent and thinner, and the mass ratio of main paint, curing agent and thinner is 1:0.2:0.6~1 (due to the deviation of customer's construction habit, thinner such as Specifically, the construction of different people has an impact on the paint film, so the scope of use is set here). in:

[0083] The components in the main paint are specifically:

[0084] Elastic polyester resin 25kg,

[0085] Vinyl chloride resin solution 15kg,

[0086] Cyclohexanone 5kg,

[0087] Propylene glycol methyl ether acetate 10kg,

[0088] Matting powder 7kg,

[0089] Add 1kg of leveling agent BYK-306,

[0090] Add 1kg of leveling agent TECH-A255,

[0091] Add 0.5kg of drier T-19,

[0092] Organic bismuth zinc drier 0.5kg,

[0093] Xylene 15kg,

[0094] Butyl acetate 20kg.

[0095] The preparation method of main paint is:

[0096] S1: Add elastic polyester resin, vinyl chloride resin solution, cyclohexanon...

Embodiment 2

[0118] In this embodiment, a wood varnish is prepared, which includes a main paint, a curing agent and a thinner, and the mass ratio of the main paint, curing agent and thinner is 1:0.2:0.6-1. (Due to the deviation of the customer's construction habits, if the thinner is specific, the construction of different people will affect the paint film, so the scope of use is set here). in:

[0119] The components in the main paint are specifically:

[0120] Elastic polyester resin 40kg,

[0121] Vinyl chloride resin solution 10kg,

[0122] Cyclohexanone 3kg,

[0123] Propylene glycol methyl ether acetate 6kg,

[0124] Matting powder 4.5kg,

[0125] Add 0.5kg of leveling agent BYK-306,

[0126] Add 0.5kg of leveling agent TECH-A255,

[0127] Add 0.3kg of drier T-19,

[0128] Organic bismuth zinc drier 0.2kg,

[0129] Xylene 20kg,

[0130] Butyl acetate 15kg.

[0131] The preparation method of main paint is:

[0132] S1: Add elastic polyester resin, vinyl chloride resin solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com