Textile processing edge cutting device with waste recycling function

A waste recycling and functional technology, which is applied in the cutting of textile materials, metal processing, textiles and paper making, etc., can solve the problems of inability to recycle waste materials, and achieve the effects of convenient centralized processing, easy buffering, and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

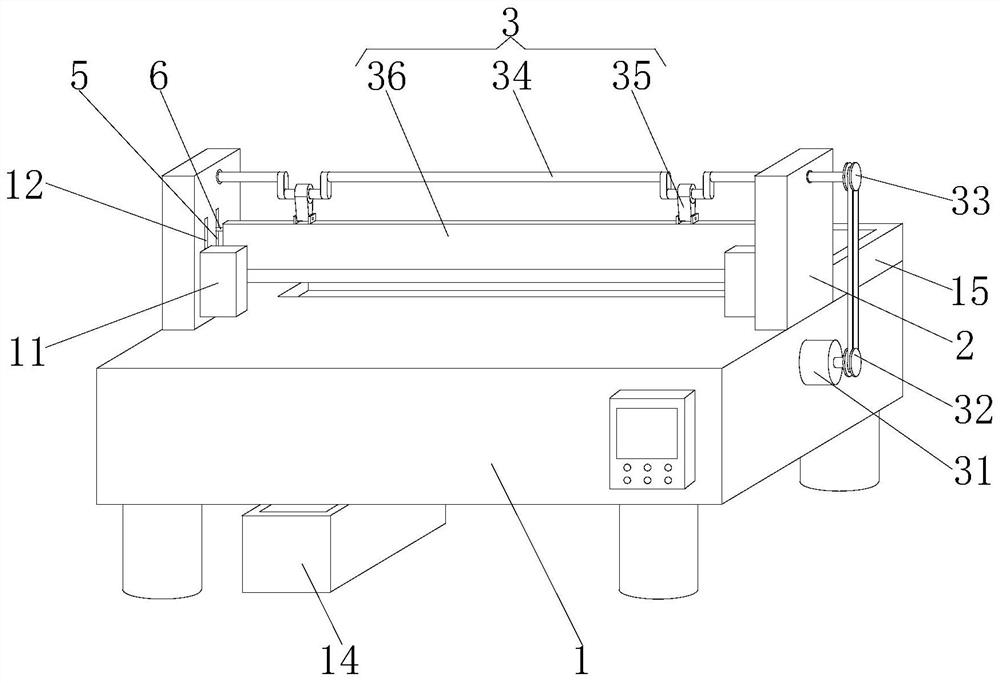

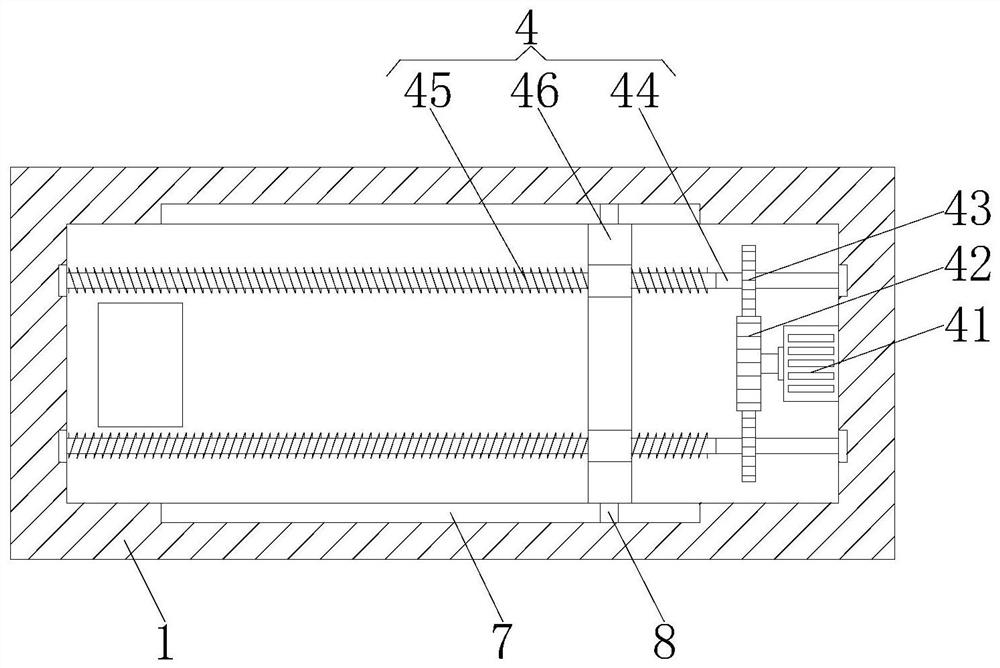

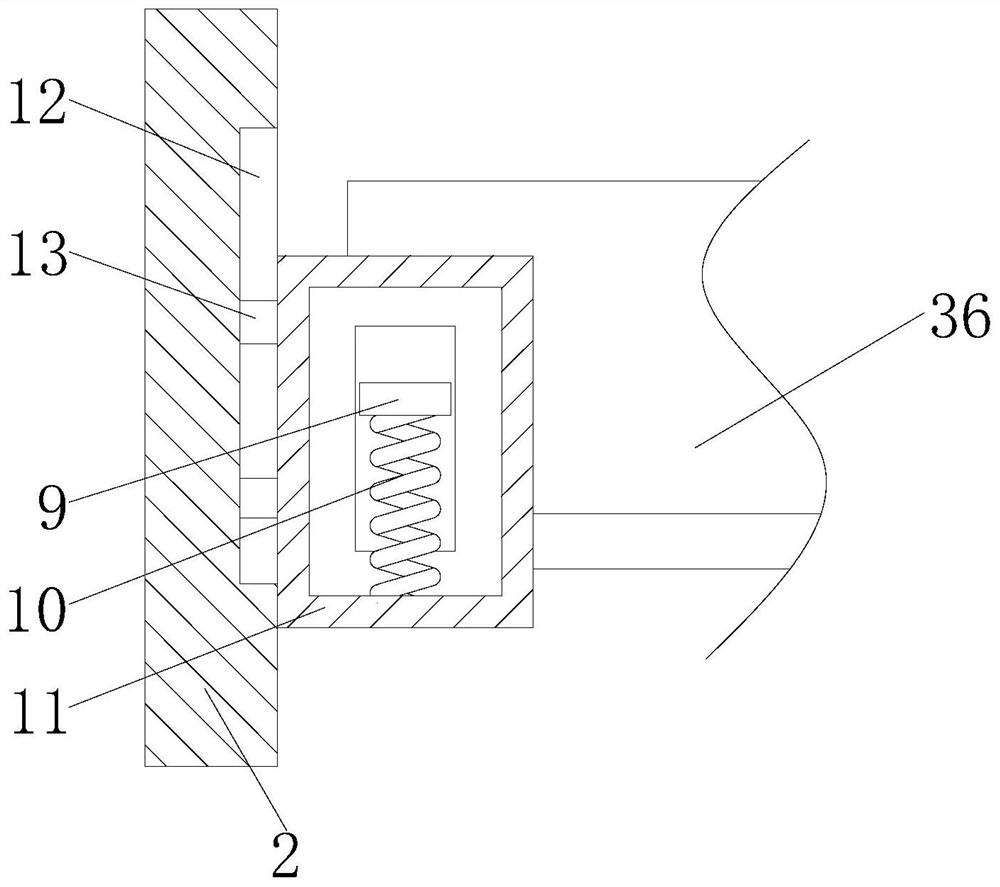

[0023] Please refer to figure 1 , figure 2 and image 3 ,in figure 1 A structural schematic diagram of a preferred embodiment of a textile processing edge trimming device with waste recycling function provided by the present invention; figure 2 for figure 1 The structural top view section view of the shown box; image 3 for figure 1 The structural sectional view of the movable box shown is a textile processing edge trimming device with waste recycling function, which includes a box body 1, and supporting legs are bolted around the bottom of the box body 1, and support legs on both sides of the top of the box body 1 A support plate 2 is bolted to the center, a cutting mechanism 3 is provided on the opposite side of the support plate 2, a first through groove is opened on the back of the top of the box body 1, and the inner cavity of the box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com