Underground cavern consolidation grouting method under high external water pressure dynamic water condition

A technology for consolidating grouting and underground caverns, applied in infrastructure engineering, protection devices, buildings, etc., can solve problems such as water gushing, and achieve the effect of reasonable and feasible technology, cost saving, and quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

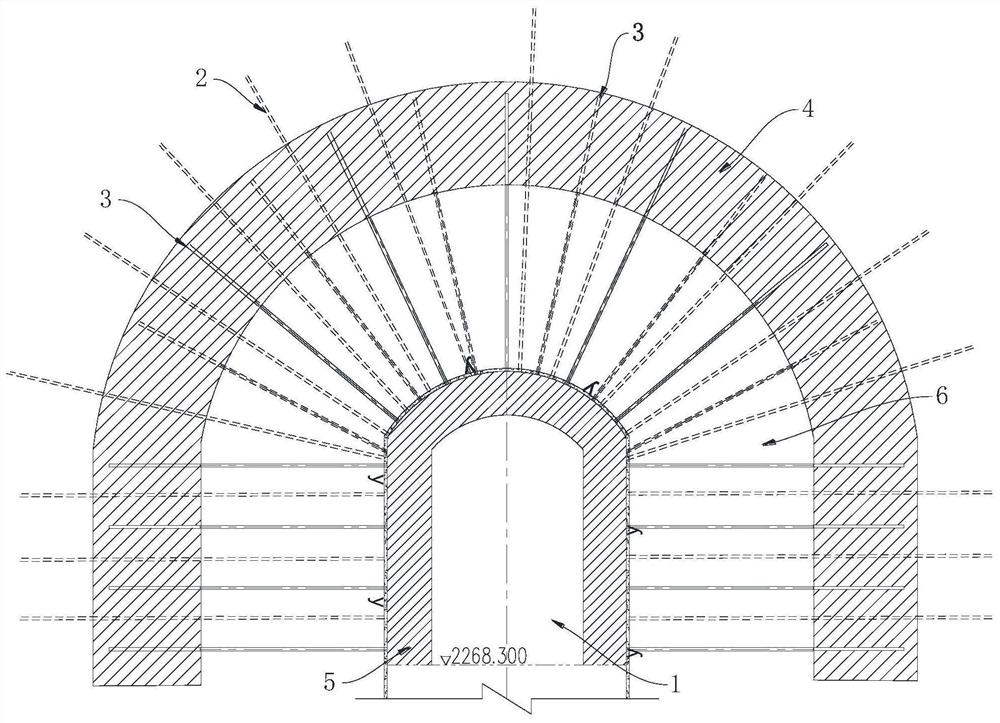

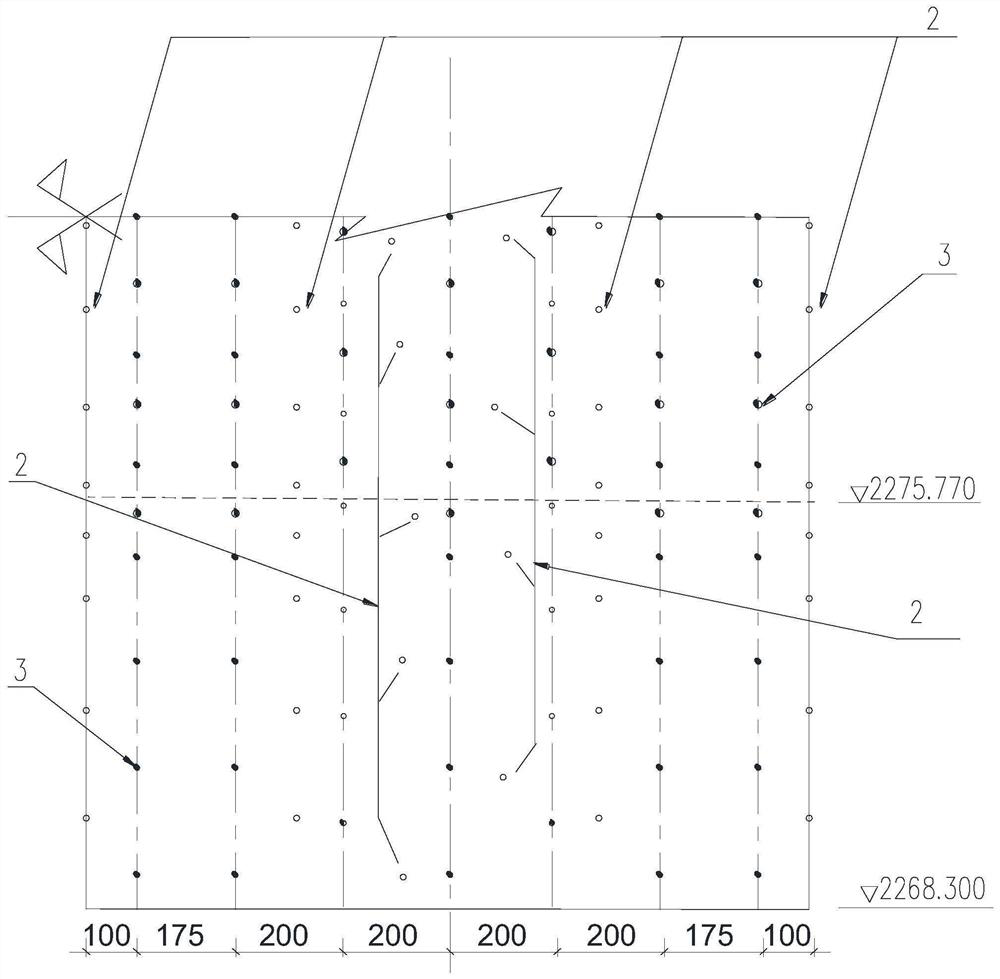

[0053] The present invention will be further described below by taking the consolidation grouting of the underground sluice chamber of the reconstruction vent tunnel of the Duonuo Hydropower Station in Jiuzhaigou County, Sichuan Province as an example. Under the condition of high external water pressure and dynamic water, the consolidation grouting method of underground caverns adopts the strategy of orderly drainage of deep drainage holes and peripheral sealing and blocking, supplemented by rock surface sealing, for seepage and gushing water. The basic conditions for lining concrete pouring and subsequent consolidation grouting construction, refer to figure 1 and figure 2 , including the following steps:

[0054] S1. Drill deep drainage holes on the rock wall of the underground cavern to conduct concentrated drainage of seepage and gushing water.

[0055] Due to the well-developed fissures in the surrounding rock of the underground sluice chamber, seepage gushing water eme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com