Method and apparatus for advanced treatment and reclamation of industrial wastewater

A technology for advanced treatment and industrial wastewater, applied in the direction of aerobic process treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of difficult COD reduction, differences in technical methods, high cost of filtration or chemical treatment, etc. Achieve the effect of reasonable technology and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

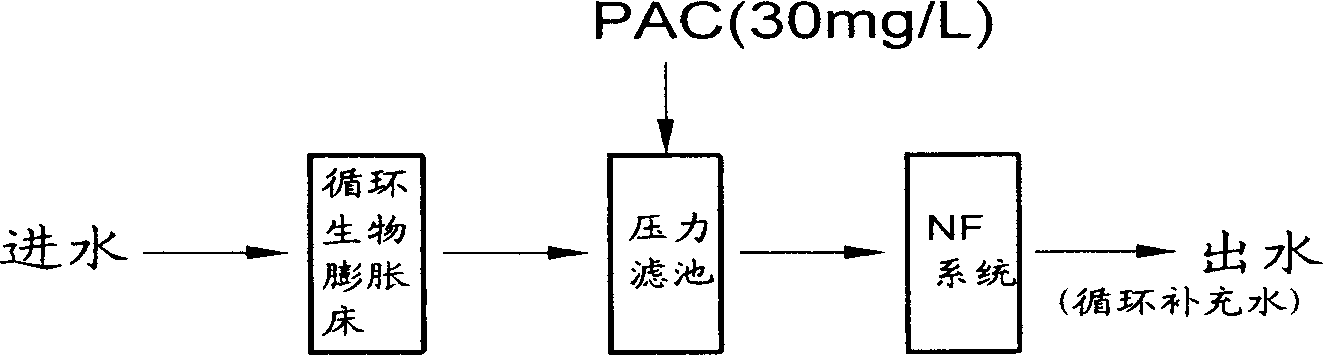

[0032] Example 1: The water quality components of oil refinery wastewater are very complex. In addition to oil, ammonia nitrogen, sulfur, phenol, and cyanide, it also contains benzene, ketones, ethers, organic phosphorus, metal salts, etc., and the concentration of organic matter is high, mostly toxic and harmful substances. Difficult to deal with. After the secondary treatment, the COD is still around 80~100mg / L, the suspended solids are around 20~30mg / L, the total hardness is around 200~300mg / L, and the turbidity is also high. It must go through a series of advanced treatments. Only then can it be reused. craft see figure 2 , See Table 1 for water quality indicators after treatment.

[0033] After the secondary biochemical discharge water is treated by the circulating biological expanded bed, pressure sand filter system and NF system, the indicators such as COD, ammonia nitrogen, SS, sulfide, phenol, turbidity, and total iron all reach the quality of circulating water rep...

example 2

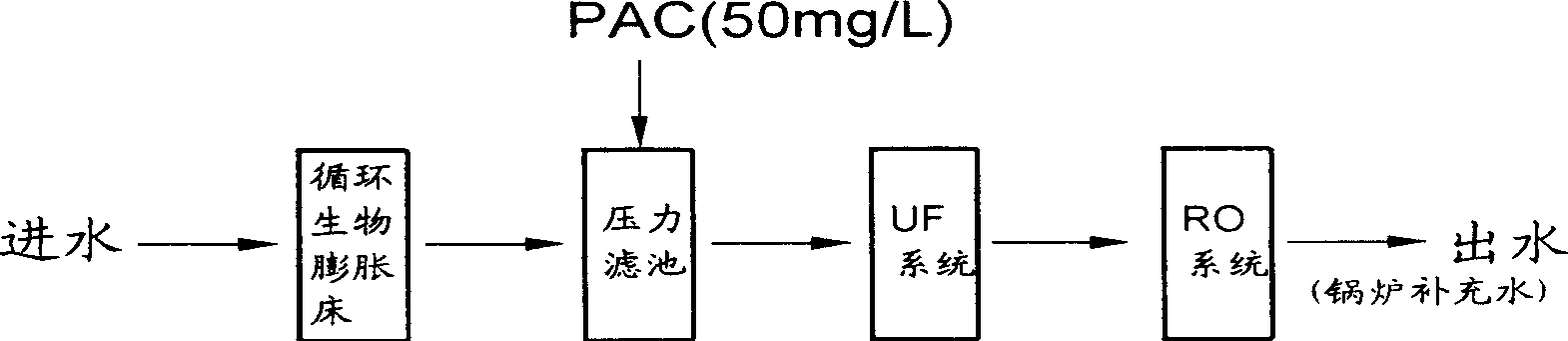

[0034] Example 2: The secondary biochemical discharge water of oil refinery wastewater is reused as boiler feed water after being treated by circulating biological expanded bed, pressure sand filter system, UF and RO system, see process image 3 , See Table 2 for water quality indicators after treatment. After the secondary discharge water is treated by UF ultrafiltration and RO reverse osmosis system, various pollutant indicators and salt indicators are reduced to trace amounts, and the desalination effect is obvious. However, the conductivity index and silica index are sometimes too high, which is not suitable for desalination, and further desalination is required through anion and cation exchangers.

example 3

[0035] Example 3. The secondary biochemical effluent of printing and dyeing wastewater is treated by circulating biological expansion bed, pressure sand filter system and RO system and then reused for the production of make-up water. The process is shown in Figure 4 , See Table 3 for water quality indicators after treatment.

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com