Helicopter pumping unit

A pumping unit and direct-lift technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the restrictions on popularization and application of beamless pumping units, high power consumption of motors, and large space occupation and other issues, to achieve the effect of novel design, improved operating efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

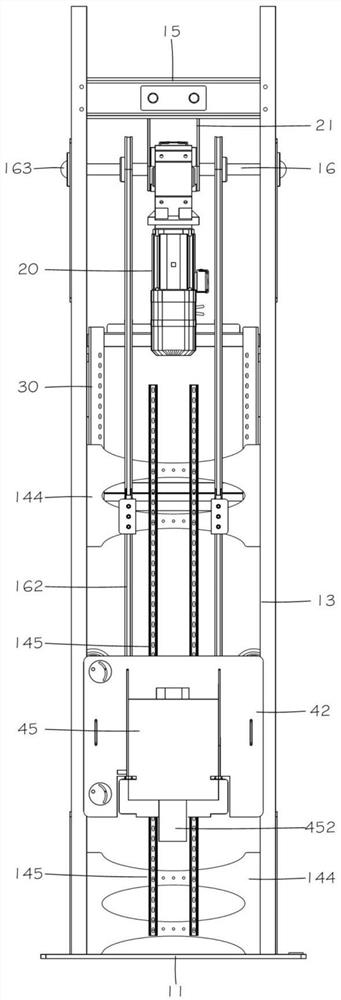

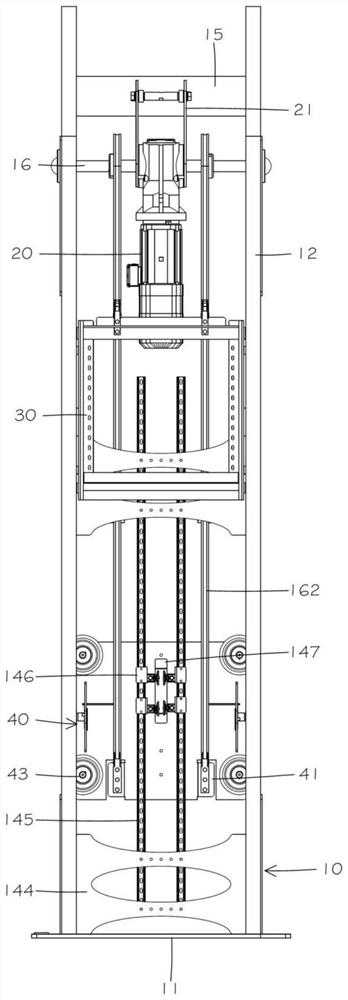

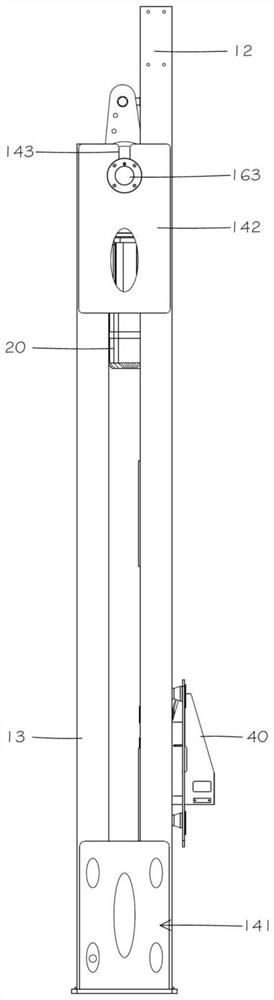

[0031] like Figure 1 to Figure 10 The helical pumping unit of the present invention shown includes a mounting bracket 10 , a geared motor 20 , a counterweight 30 and a connecting device 40 . The structure is reasonable, the design is novel, and the volume of the pumping unit is greatly reduced through the close cooperation of the installation bracket, the counterweight and the connecting device.

[0032] The mounting bracket 10 includes a base 11, a front bracket 12, a rear bracket 13, a reinforcing plate 14 and a crossbeam 15, the front bracket 12 and the rear bracket 13 are all provided with mounting grooves 131, and the reinforcing plate 14 includes a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com