Wide viscosity type liquid turbine flow sensor

A technology of flow sensor and liquid turbine, which is applied in the direction of volume/mass flow generated by mechanical effects, and by detecting the dynamic effects of fluid flow, etc., which can solve problems such as large errors, and achieve the effect of improving instrument performance, stabilizing performance, and maintaining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

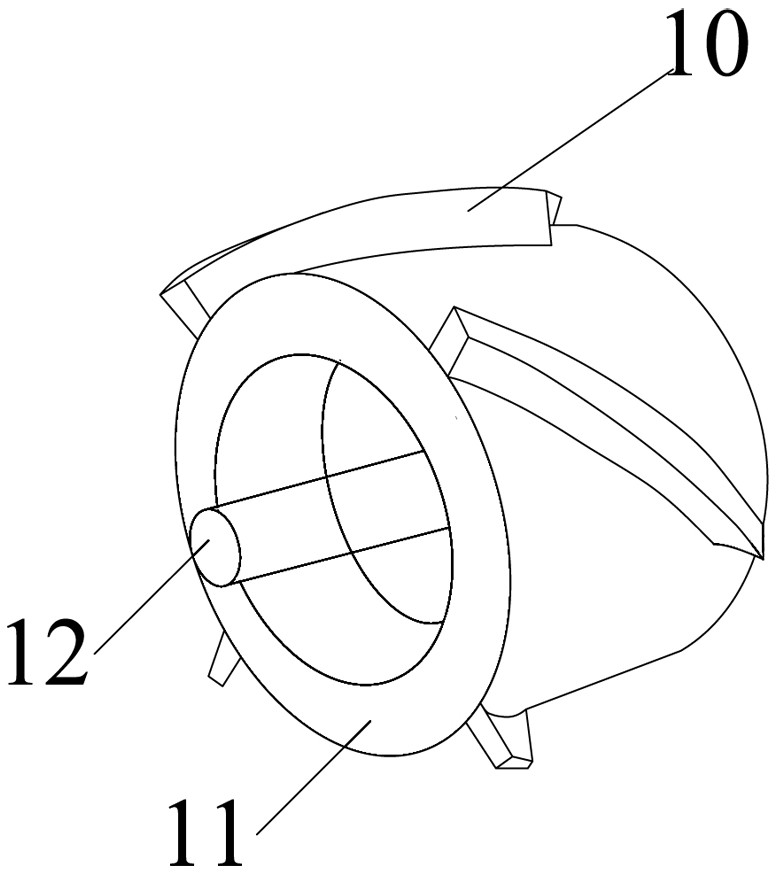

[0015] The liquid turbine flow sensor of the present invention is mainly for improvements to the impeller portion. Such as figure 1 As shown, the axle shaft 12 is provided on the axial center line of the impeller 11, and the outer end of the wheel shaft 12 projects the end face of the impeller to support the impeller in the housing of the turbine flow sensor. The four blade 10 are evenly distributed on the wheel surface of the impeller 11, and each of the blade 10 is fixedly attached to the wheel surface of the impeller 11. The blade distribution form on the impeller 11 is that the end of the front blade is inserted in the impeller axis of the rear blade. That is, the two adjacent blades 10 have no slit in the axial direction of the impeller 11, there is no overlap, and a closed loop structure is formed. Further, the ratio of the diameter of the impeller 11 and the housing of the mounting impeller is 0.8: 1.

[0016] The outer diameter of the housing of the liquid turbine flow se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com