Ultrasonic probe device and workpiece sound velocity measuring method

An ultrasonic probe and measurement method technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, measuring devices, and the use of sonic/ultrasonic/infrasonic waves to analyze solids, etc. , to ensure the effect of good coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the following specific examples will further describe the present invention in detail. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

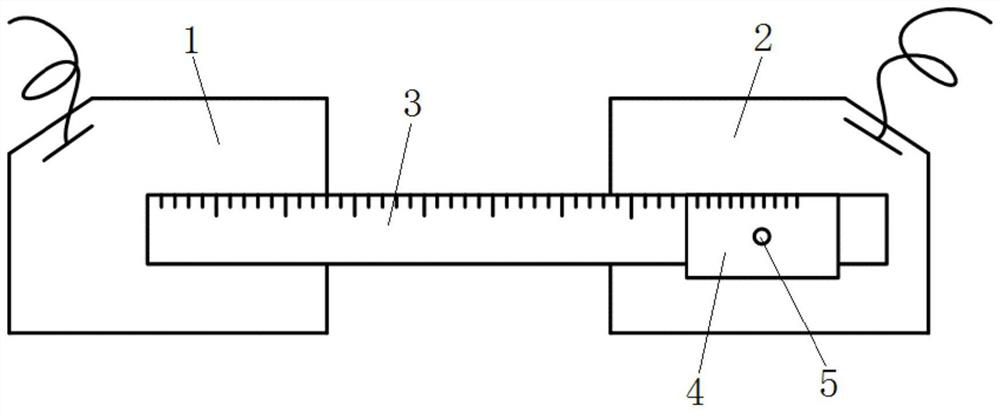

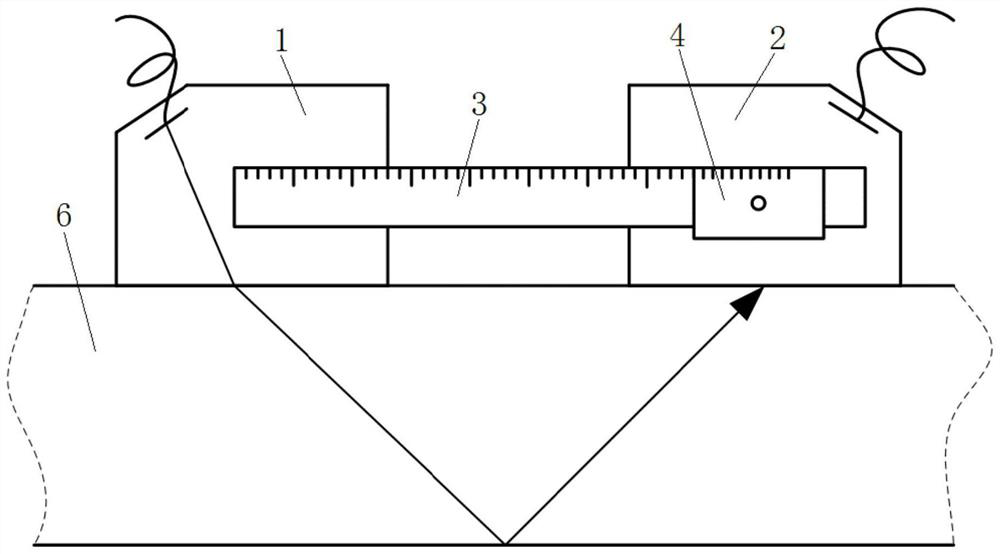

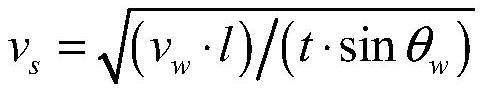

[0039] as attached Figure 1-2 As shown, the present invention provides an ultrasonic probe device, comprising a first shear wave probe 1, a second shear wave probe 2, a measuring scale 3, a vernier ruler 4 and a connector 5; the first shear wave probe 1 and the second shear wave probe 2 are both Slidingly set on the measuring stick 3, the incident angles of the first shear wave probe 1 and the second shear wave probe 2 are the same, and the incident angles of the two shear wave probes are fixed values; the measuring stick 3 is used to measure the incident point of the first shear wave probe 1 Distance from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com