Ultra-precision lathe motion control method based on fuzzy PID self-tuning calculation

A technology of motion control and self-tuning, which is applied in the field of high-precision control of moving parts and ultra-precision cutting processing, can solve the problems of insufficient precision of ultra-precision cutting, lack of self-tuning, and limited control effect, so as to improve the performance of ultra-precision cutting. Accuracy, optimized output, and the effect of improving positioning accuracy and response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

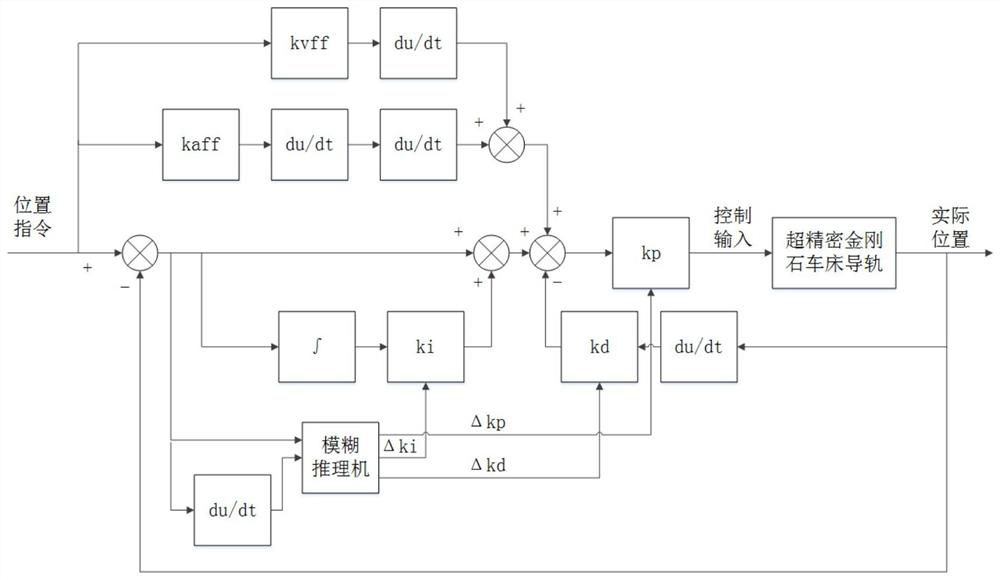

[0041] The motion control method of ultra-precision lathe based on fuzzy PID self-tuning calculation provided in this embodiment includes the following steps:

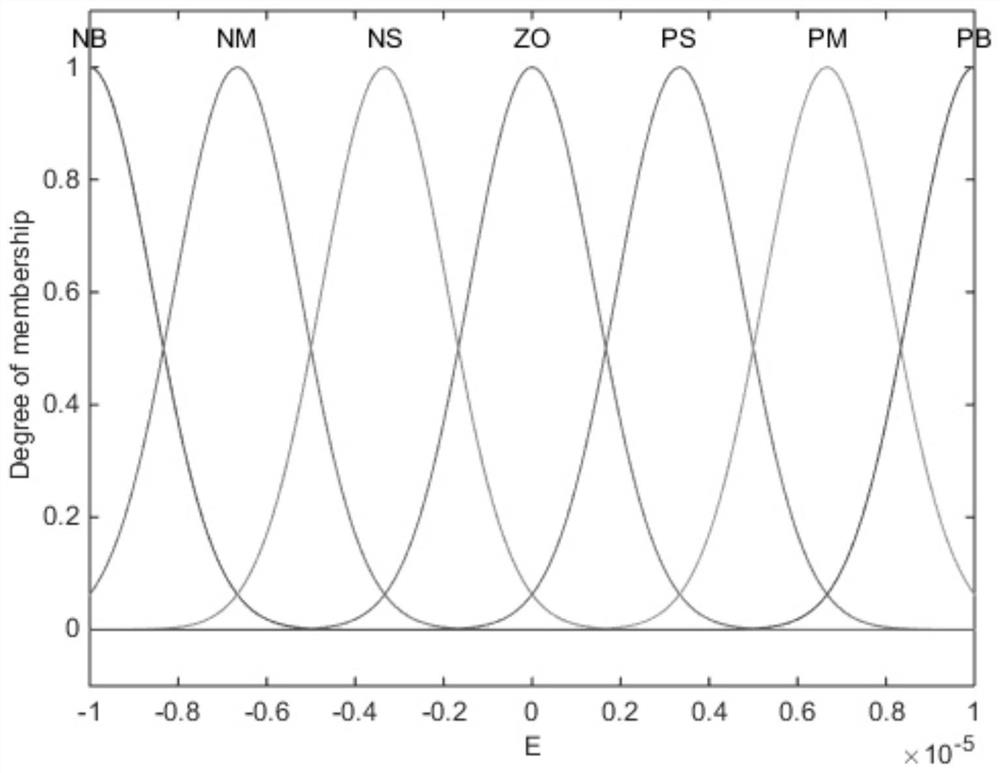

[0042] Taking the linear motion guide rail of the lathe as the controlled object, the preset position information and actual position information of the linear motion guide rail are obtained, and according to the error value and the change rate of the error value between the preset position and the actual position, the fuzzy PID control algorithm is used to calculate the control Output, the control output is input into the control system to control the motion of the linear motion guide rail. This is the main step to control the motion of the linear motion guide rail based on the fuzzy PID algorithm. Although the existing fuzzy PID control algorithm can improve the adaptability of the system to a certain extent, the control effect of fuzzy PID always depends on the selection of the initial PID parameters and the determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com