Printing and dyeing setting machine gas leakage detection system based on narrow-band Internet of things

A narrowband Internet of Things, gas leakage technology, applied in electrical components, network topology, climate sustainability, etc., can solve the problems of high cost and high latency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

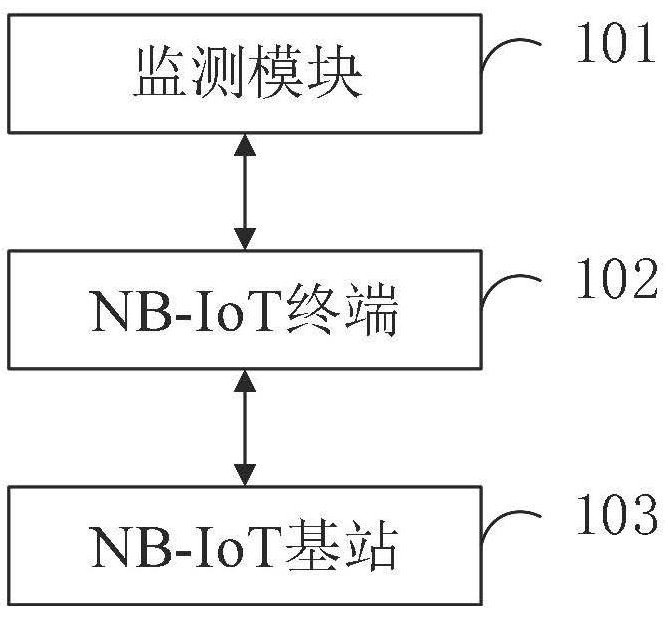

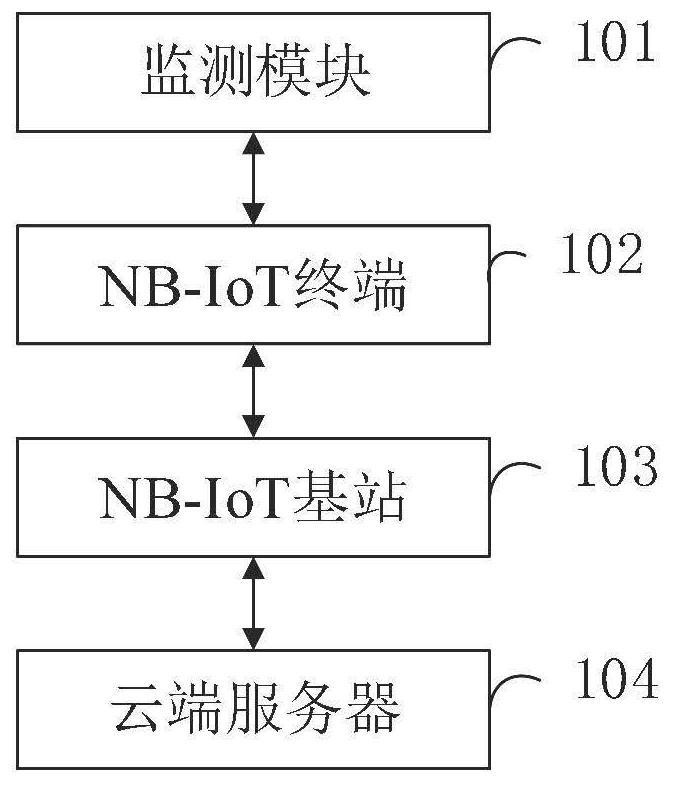

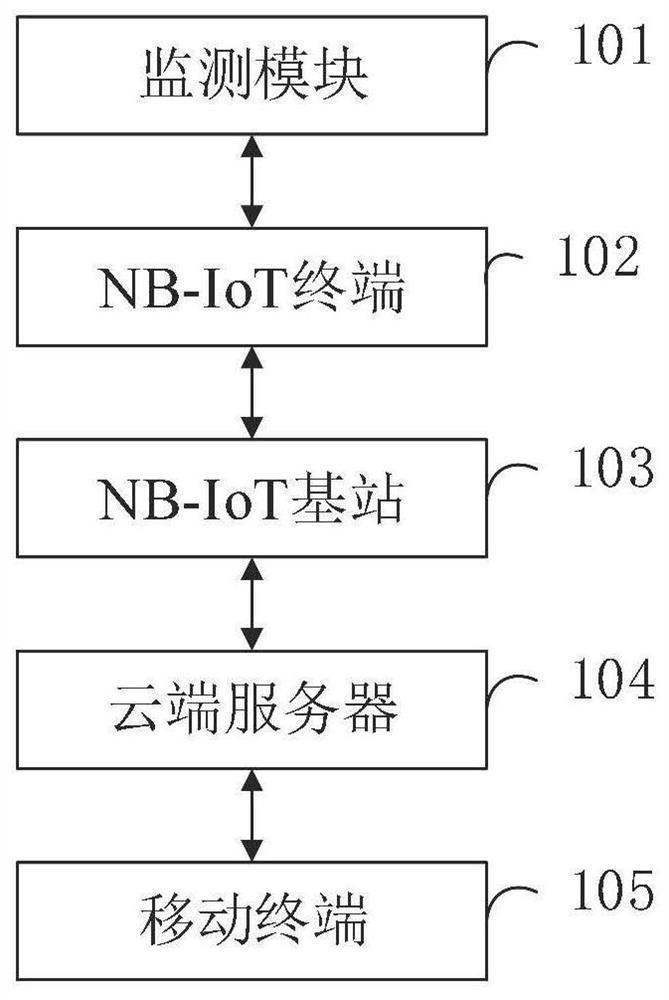

[0029] Embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although certain embodiments of the present disclosure are shown in the drawings, it should be understood that the disclosure may be embodied in various forms and should not be construed as limited to the embodiments set forth herein; A more thorough and complete understanding of the present disclosure. It should be understood that the drawings and embodiments of the present disclosure are for exemplary purposes only, and are not intended to limit the protection scope of the present disclosure.

[0030] It should be understood that the various steps described in the method implementations of the present disclosure may be executed in different orders, and / or executed in parallel. Additionally, method embodiments may include additional steps and / or omit performing illustrated steps. The scope of the present disclosure is not limited in this regard. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com