Composite absorption core and preparation method and application thereof

A technology of absorbing core and carrier layer, applied in the field of composite absorbing core and its preparation, can solve problems such as poor conductivity of absorbing core, achieve the problem of not easy to disperse, increase diffusion conductivity, and reduce the probability of occurrence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

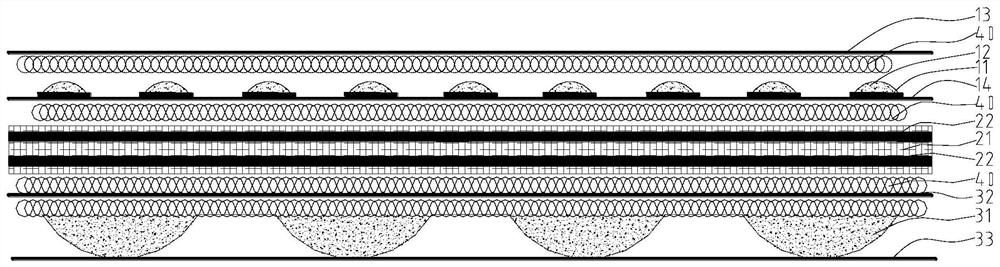

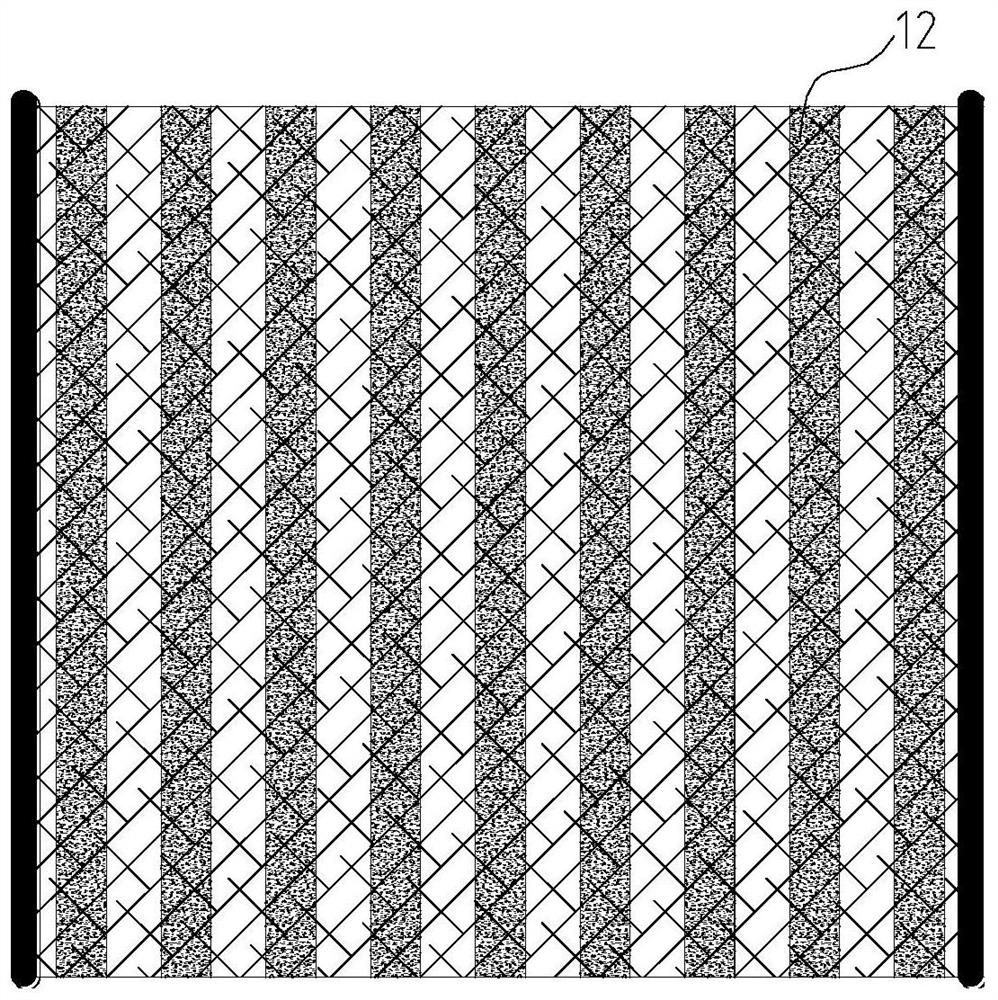

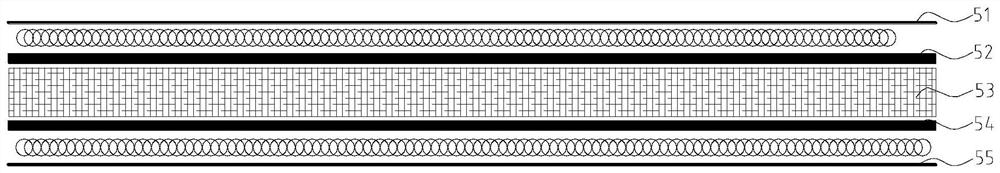

[0042] Such as Figure 1-2 As shown, a preparation method of a composite absorbent core, the composite absorbent core includes an upper layer material, a middle layer material and a lower layer material stacked in sequence, the upper layer material includes a first carrier layer 13, a second carrier layer 14, and the A diversion structure between the carrier layer 13 and the second carrier layer 14, the diversion structure includes several first strip-shaped wood pulp layers 11 arranged in sequence along the horizontal direction, and the width of the first strip-shaped wood pulp layer 11 is 10 mm, corresponding to The spacing of the adjacent two first strip-shaped wood pulp layers 11 is 10mm, and the first resin layer 12 is covered on several first strip-shaped wood pulp layers 11, and the spreading width of the first resin layer 12 is 8mm; Including the absorbent base layer 21, the absorbent base layer 21 is a fluffy non-woven fabric, composed of 70% three-dimensional hollow ...

Embodiment 2

[0051] The difference between Embodiment 2 and Embodiment 1 lies in: the specific selection of each material layer, see Table 2 below for details.

[0052] Table 2 The material list of the composite absorbent core of Example 2

[0053]

[0054]

[0055] All the other are identical with specific embodiment 1.

Embodiment 3

[0057] The difference between embodiment 3 and embodiment 1 is that: in the upper material, the width of the first strip-shaped wood pulp layer is 15mm, and the distance between two adjacent first strip-shaped wood pulp layers is 25mm, and the first resin The spreading width of the layer is 18mm; in the material of the lower layer, the width of the second strip-shaped wood pulp layer is 30mm, and the distance between two adjacent second strip-shaped wood pulp layers is 20mm.

[0058] All the other are identical with specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com