Dust removal, desulfurization and white smoke removal integrated method

A desulfurization agent and stage purification technology, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of easy leakage, large floor space, high cost, etc., so that it is not easy to leak gas, and the floor space is reduced , the effect of reducing the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, specific embodiment of the present invention will be described in further detail,

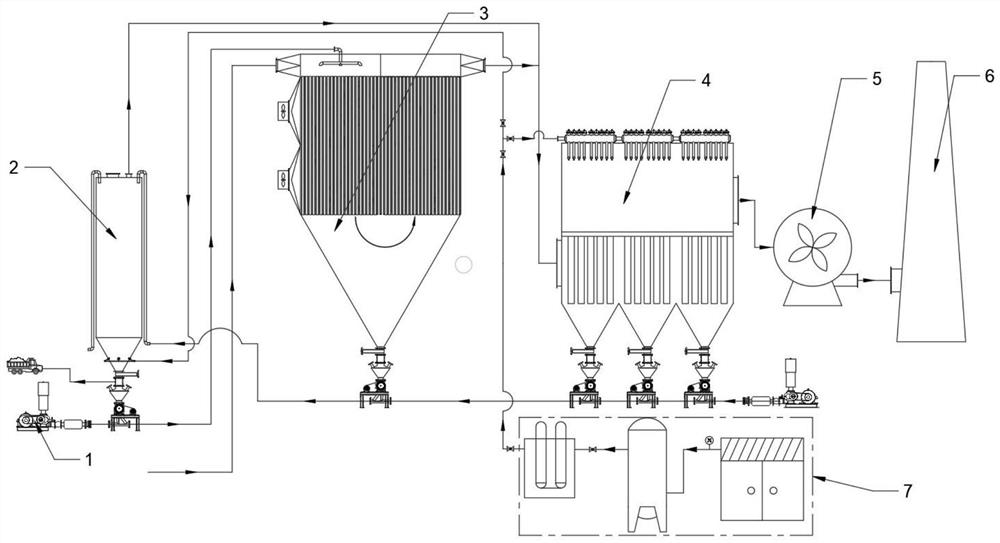

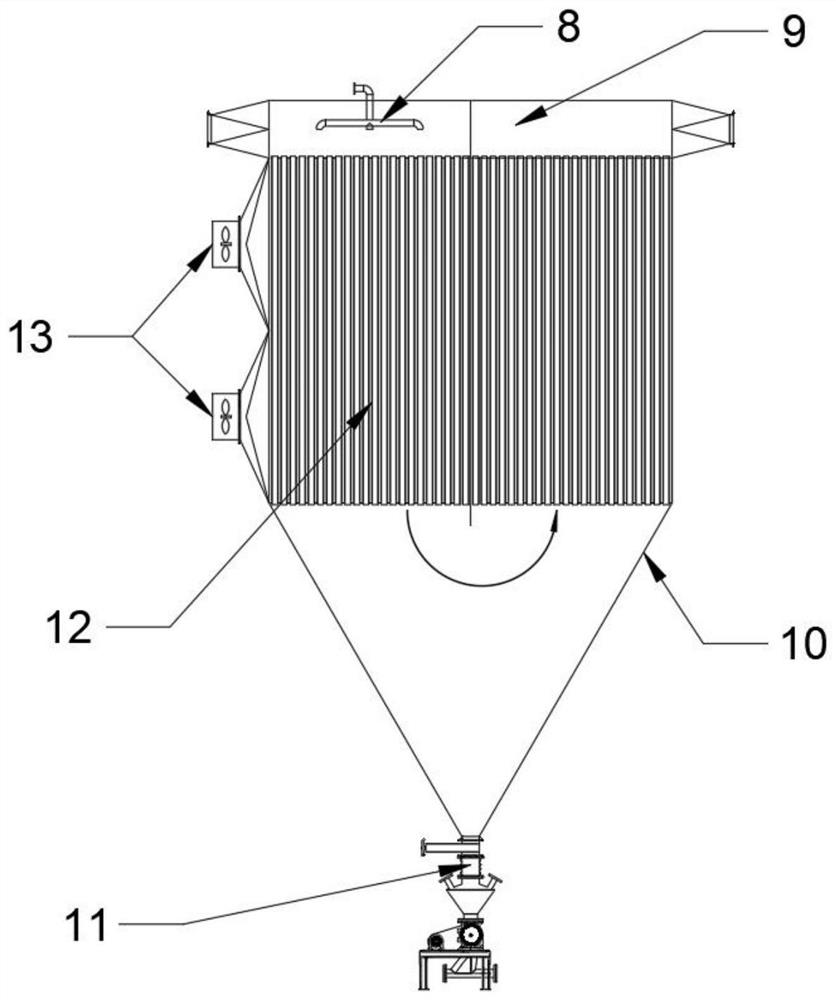

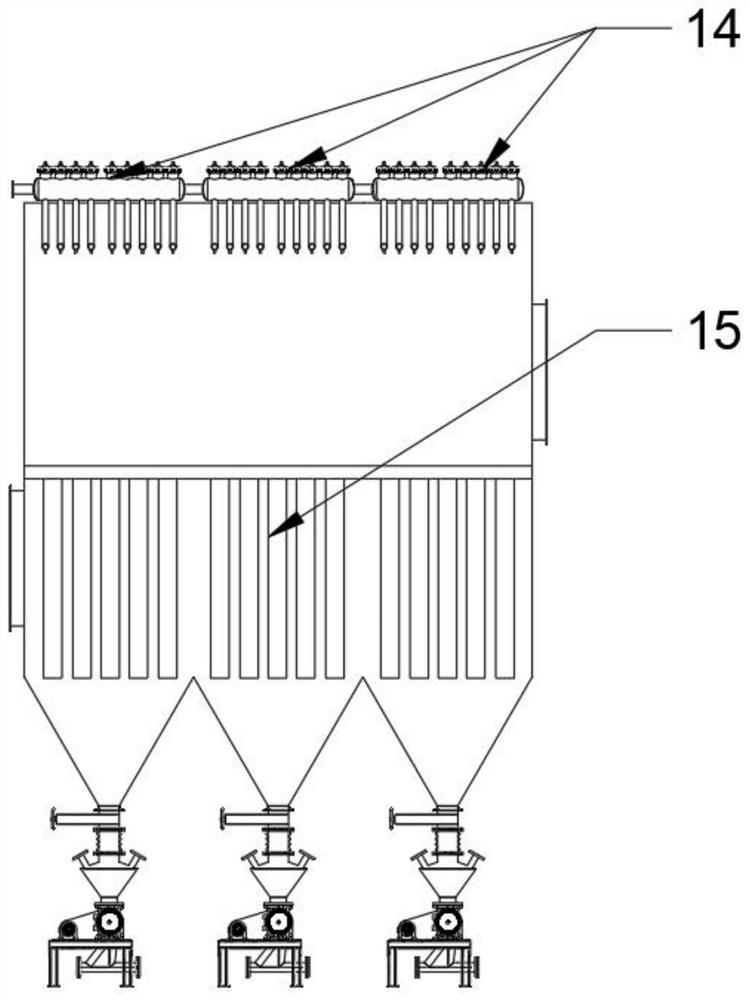

[0018] Such as Figure 1-Figure 4 As shown, an integrated method of dust removal, desulfurization, and dewhitening includes two Roots blowers (1), desulfurization agent warehouse (2), primary purification unit (3), secondary purification unit (4), induction Fan (5), chimney (6) and compressed air unit (7), the air outlet of one Roots blower (1) and the discharge port of desulfurizer warehouse (2) and the primary purification unit (3) The feed inlet is communicated with the pipeline to realize sending the desulfurizer into the primary purification unit (3), and the air inlet of the primary purification unit (3) is communicated with the external coke oven coal charging flue gas source through the pipeline, The dust outlet of the desulfurizer bin (2) and the exhaust port of the primary purification unit (3) communicate with the air inlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com