Tea seed crusher for tea oil processing

A pulverizer and tea seed technology, applied in grain processing and other directions, can solve the problems of insufficient pulverization of tea seeds, inability to effectively use tea seeds, poor pulverization effect, etc., and achieve the effects of good pulverization effect, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

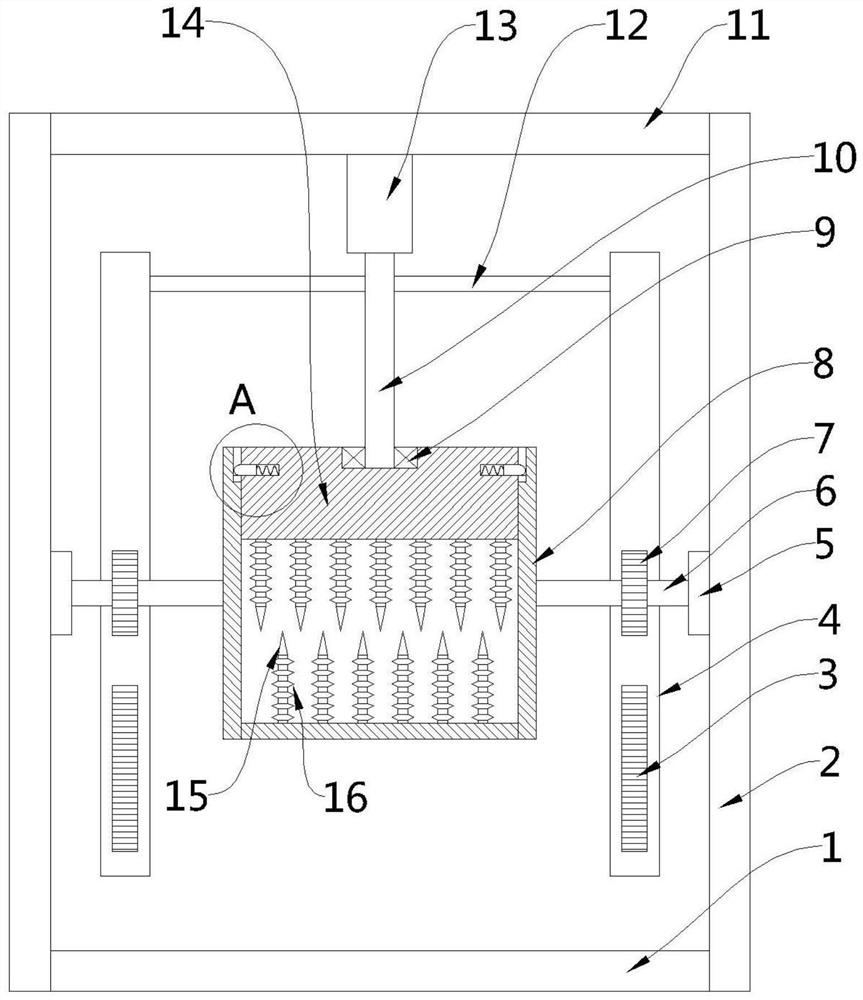

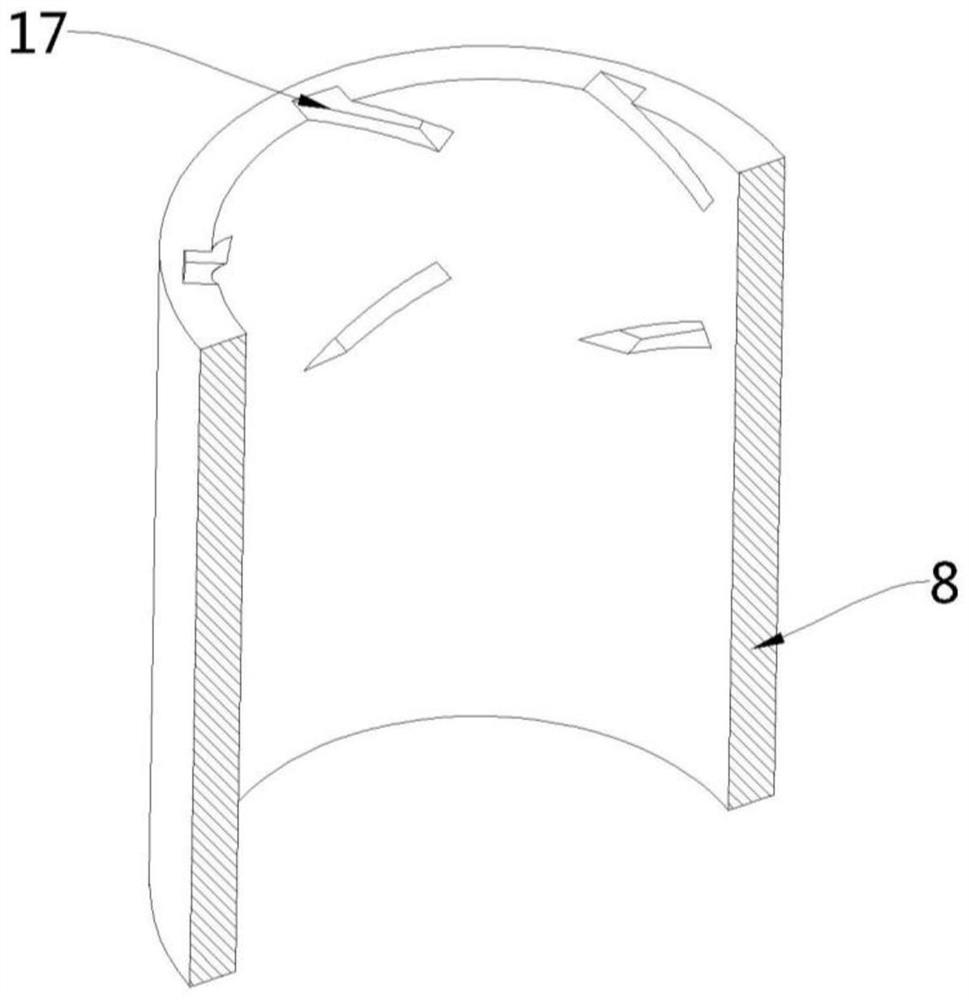

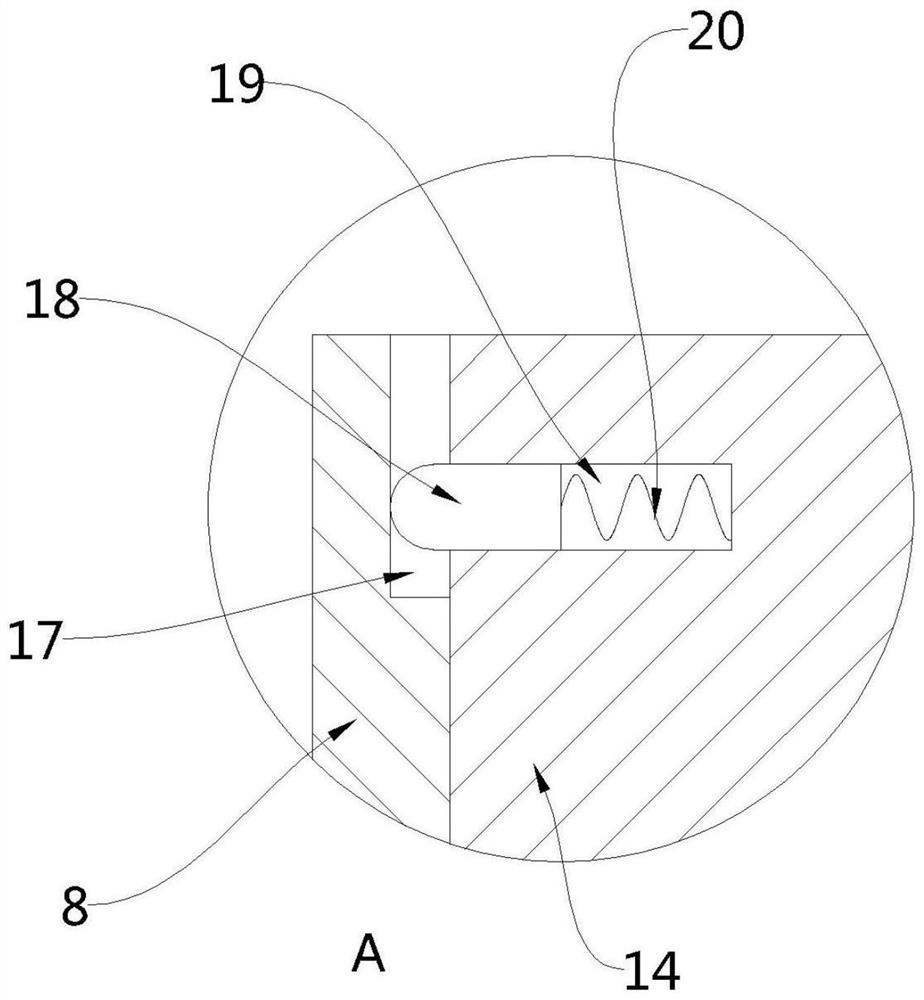

[0024] see Figure 1-3 , the present embodiment provides a tea seed grinder for tea oil processing, comprising a bottom plate 1, vertical plates 2 fixedly arranged on both sides of the bottom plate 1, and a top plate 11 fixedly installed on the upper parts of two sets of vertical plates 2, A storage cylinder 8 is arranged between the two sets of vertical plates 2 , a crushing assembly is arranged above the storage cylinder 8 , and a bottom of the top plate 11 is provided for driving the crushing assembly to move down to enter the storage cylinder 8 . The first driving assembly of the cavity, specifically, the crushing assembly includes a pressing plate 14, and the bottom of the pressing plate 14 and the inner bottom of the storage cylinder 8 are fixedly equipped with a number of pinches 15, and the pinning teeth 15 at the bottom of the pinching plate 14 are connected with the storage The slotting teeth 15 at the inner bottom of the barrel 8 are misaligned with each other, and ...

Embodiment 2

[0030] see figure 1 , a tea seed grinder for tea oil processing. Compared with Embodiment 1, the outer wall of the storage tube 8 is fixed with support rods 6 on both sides of the outer wall of the present embodiment, and the support rods 6 are far away from the side of the storage tube 8. One end is respectively rotatably connected to the corresponding vertical boards 2 , and a second drive assembly for driving the storage tube 8 to turn over is provided between the two groups of vertical boards 2 .

[0031] After the tea seeds are crushed, the hydraulic cylinder 13 can drive the piston rod 9 to move upwards, and then drive the pressure plate 14 to move upwards to be removed from the inside of the storage tube 8. At this time, the second drive assembly can be used to drive the storage tube 8 to turn over, so that the storage tube 8 The crushed tea seeds inside are poured out to realize the discharge of tea seeds.

[0032] Specifically, the end of the support rod 6 away from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com